vertical packing machine

Biscuit & cookies packaging solution refers to integrated packaging systems for cookies and biscuits that protect fragile products from breakage, keep crispness, and deliver consistent shelf-ready presentation at industrial speed.

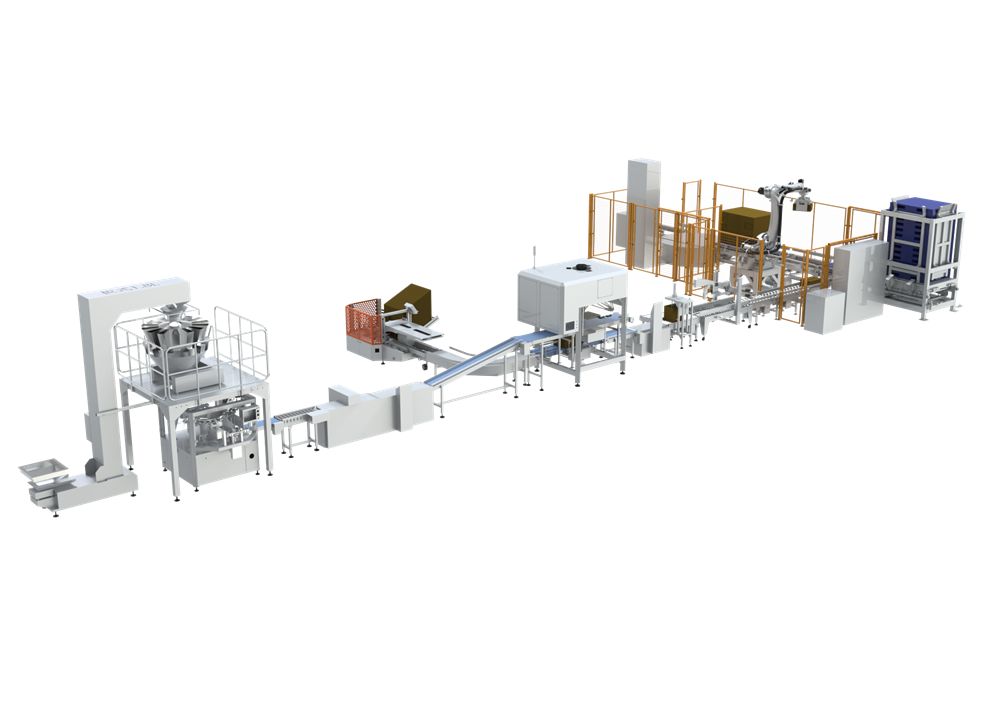

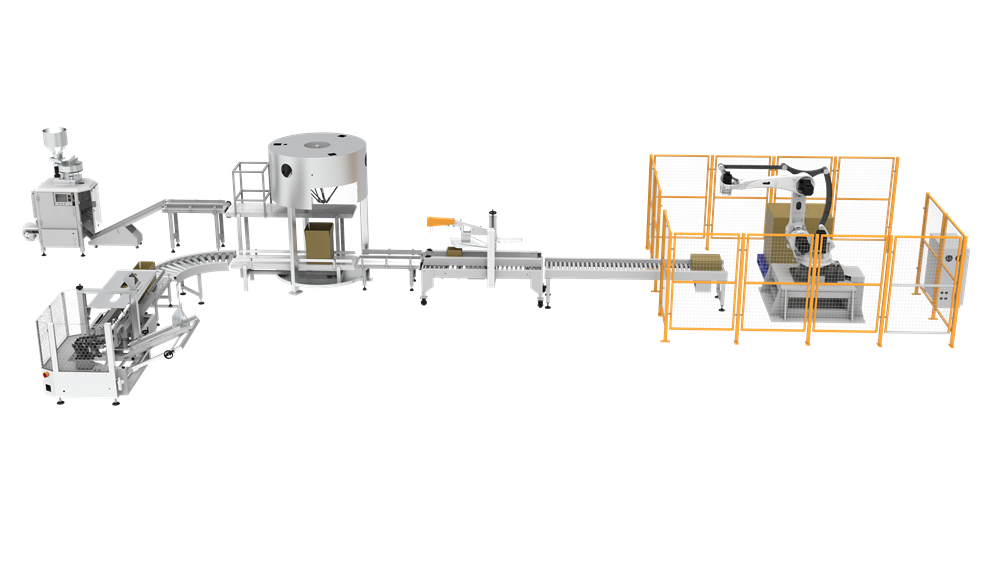

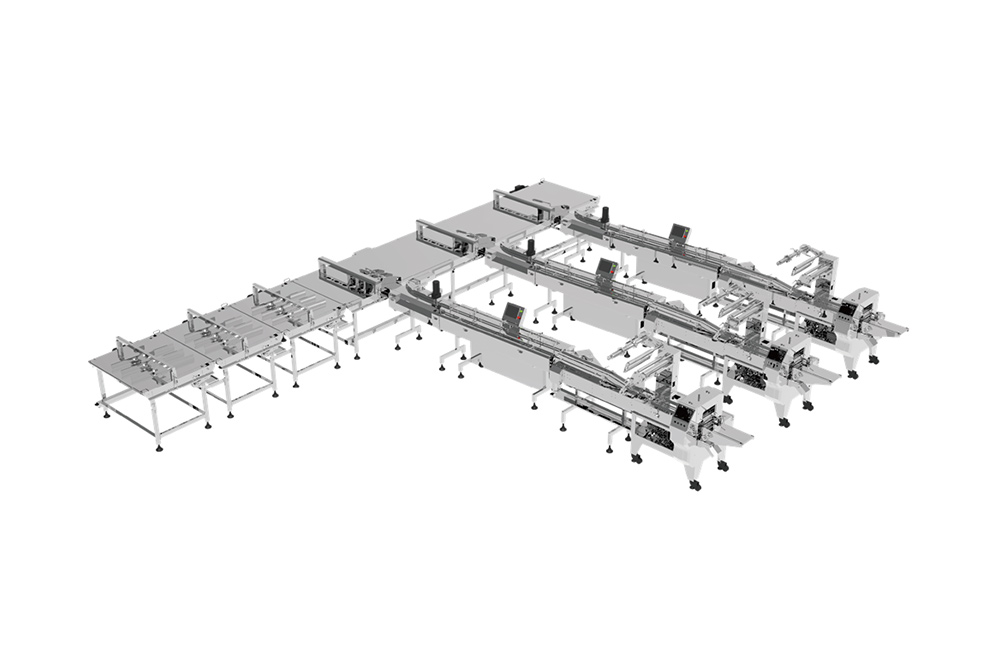

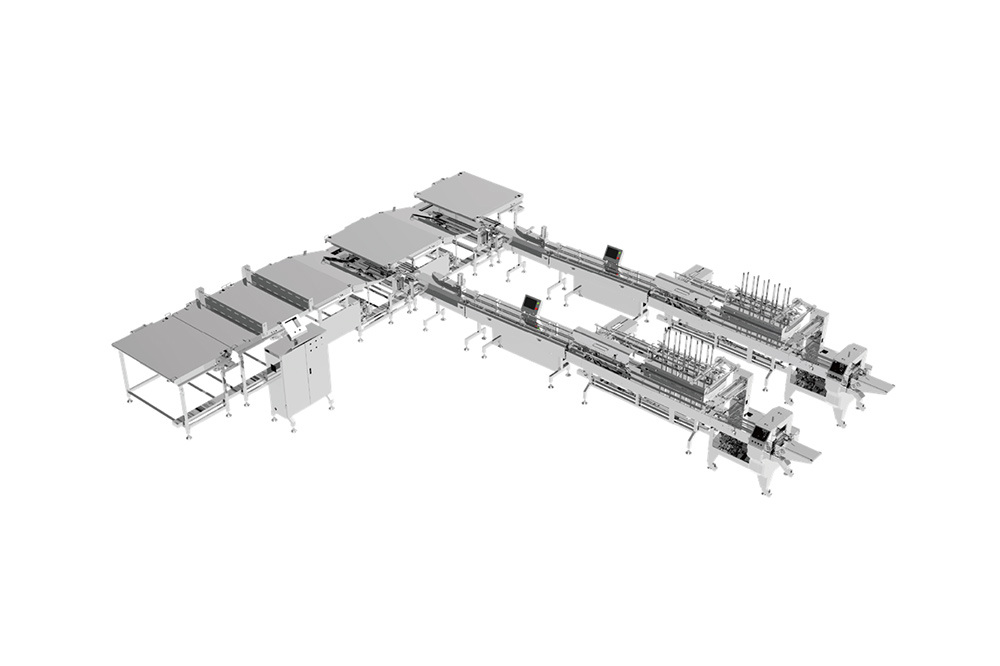

A complete solution may include a cookie packing machine (primary packing), a cookie wrapping machine (flow wrapping for pillow packs and multipacks), and optional modules such as checkweighing, metal detection, coding, and cartoning. For manufacturers aiming to upgrade OEE and reduce waste, a complete cookie packaging line can be configured from feeding to secondary packaging.

Soontrue provides modular cookie packaging solutions that scale from a single machine to full automation, suitable for both mass production and premium packs.

Explore how different cookie and biscuit formats are packed with automated equipment. The videos below demonstrate typical configurations such as pillow packs, multipacks, on-edge stacks, tray + flow wrap, and cartoning integration—helping you understand how to build stable biscuit packaging machines and packaging lines for your products.

Cookies and biscuits are sensitive to handling, crumbs, and moisture. Typical packaging challenges include:

To solve these issues, manufacturers often adopt automated biscuit packaging solutions with gentle feeding, stable sealing, and integrated line control.

Soontrue offers packaging formats based on product type, pack style, and target speed. Below is a practical solution matrix:

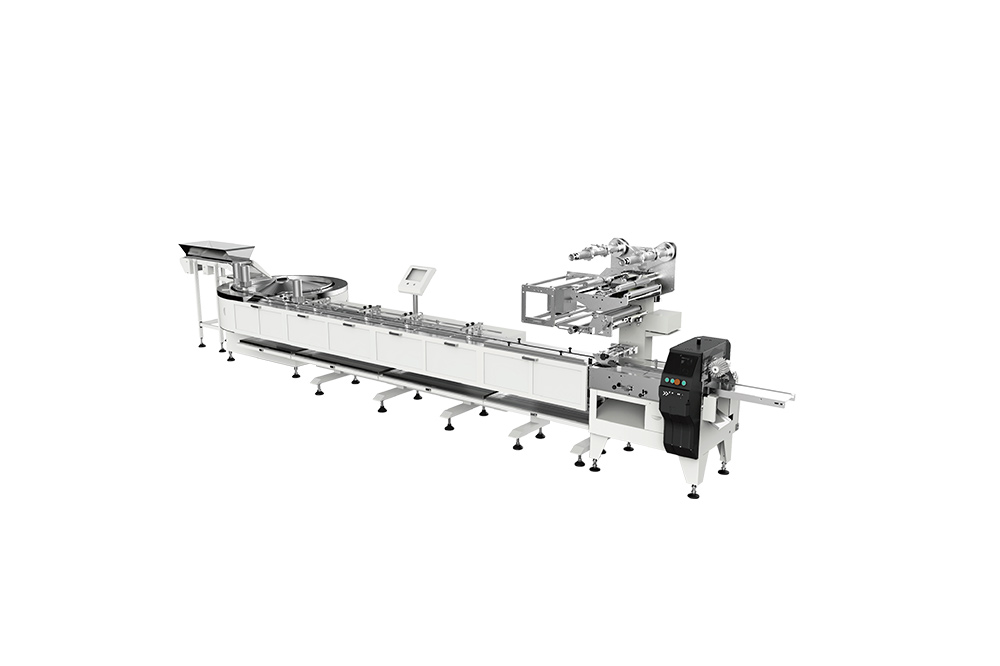

A cookie wrapping machine (horizontal flow wrapper) is ideal for single cookies, sandwich biscuits, and multipacks. It supports stable sealing and gentle handling, reducing breakage while keeping pack appearance consistent.

In real production, “cookies packing machine” often describes a complete packing setup, which may include feeding, counting/collation, and flow wrapping or bagging. This is suitable for factories running multiple SKUs and needing stable output.

A cookie packaging machine based on VFFS is suitable for mini cookies, small biscuits, or bulk bags where flexible bag size and efficient bagging are required.

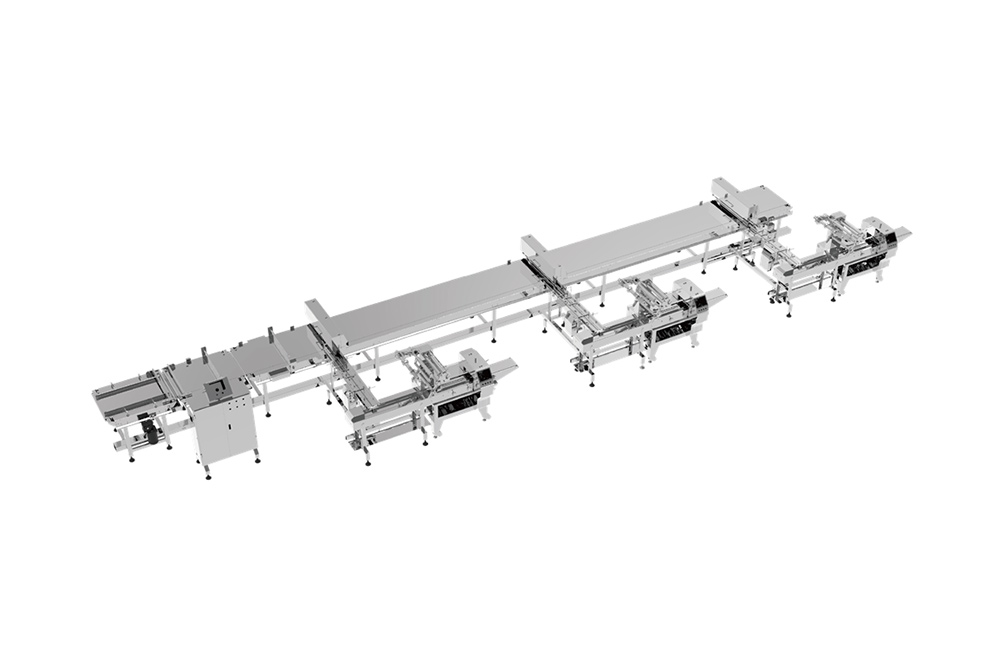

A complete cookie packaging line integrates feeding and alignment, primary packaging, and optional cartoning/case packing. It reduces manual handling, improves OEE, and standardizes pack presentation for retail.

For premium display and convenience, premade pouch packing and cartoning solutions can be combined into cookie packaging solutions for stand-up pouches, zipper pouches, assorted packs, and retail-ready cartons.

Share your cookie/biscuit size, packaging format, and target speed—our team will recommend a suitable machine model and a complete line layout.

Goal: Improve output and reduce breakage in multipacks.

Solution: Automatic feeding + collation + high-speed flow wrapper with stable sealing.

Result: More consistent presentation, improved line efficiency, and reduced product waste.

Goal: Protect stacked biscuits and improve shelf appearance.

Solution: On-edge alignment + controlled transfer + flow wrap system optimized for fragile products.

Result: Fewer tipped stacks, better pack appearance, and more stable high-speed production.

Q1: What is a cookies packing machine used for?

A: It is used to pack cookies or biscuits into the desired format. In many factories, it refers to a complete packing setup including feeding, counting/collation, and primary packaging.

Q2: What is the difference between a cookie packaging machine and a cookie wrapping machine?

A: A cookie wrapping machine typically refers to a horizontal flow wrapper for pillow packs and multipacks, while a cookie packaging machine can include flow wrappers, VFFS machines, or pouch packing machines depending on the pack format.

Q3: How do I build a cookie packaging line for high-speed production?

A: Start from stable feeding and alignment, then select primary packaging (flow wrap/VFFS/pouch), and add optional cartoning/case packing to match your logistics and retail needs.

Q4: What are automated biscuit packaging solutions and when are they needed?

A: They are integrated systems designed to reduce manual handling, improve OEE, and keep pack quality stable—ideal for high volume, multi-SKU production, or premium retail formats.

Q5: Which biscuit packaging machines are best for fragile biscuits?

A: Flow wrappers with gentle feeding and stable sealing are commonly used. For stacked products, on-edge systems help reduce tipping and breakage.

Q6: How can I reduce breakage and crumbs in a biscuits packaging line?

A: Use controlled transfer, gentle conveying, effective crumb management, and sealing-area protection to reduce contamination and downtime.

Q7: What packaging systems for cookies help extend shelf life?

A: High-integrity sealing and suitable barrier films are essential. Optional MAP or deoxidizer integration can be used if needed.

Q8: What packaging formats are common for cookie packaging solutions?

A: Pillow packs, multipacks, on-edge stacks, tray + flow wrap, stand-up pouches, zipper pouches, and retail cartons.

Q9: How do I choose between flow wrapping and VFFS for cookies?

A: Flow wrapping is common for single packs and multipacks with strong presentation needs, while VFFS is suitable for small pieces or bulk bags requiring flexible bag sizing.

Q10: What information is needed to recommend the right cookie packaging line?

A: Product dimensions and weight, fragility/stacking requirements, target speed (packs/min), packaging format, film or pouch type, and whether cartoning/case packing is required.

Recommended models depend on your pack style and production goals:

To recommend the right model faster, please share:

Product size & weight, packaging format (pillow pack/multipack/on-edge/tray/pouch/carton), target speed, film/pouch type, and whether you need cartoning or end-of-line integration.