TD200L Vertical Premade Pouch Packing Machine

TD200L Vertical Premade Pouch Packing Machine Typical Applications

- Rice and grains

- Beans, lentils, and pulses

- Nuts and dried fruits

- Snacks and small solid foods

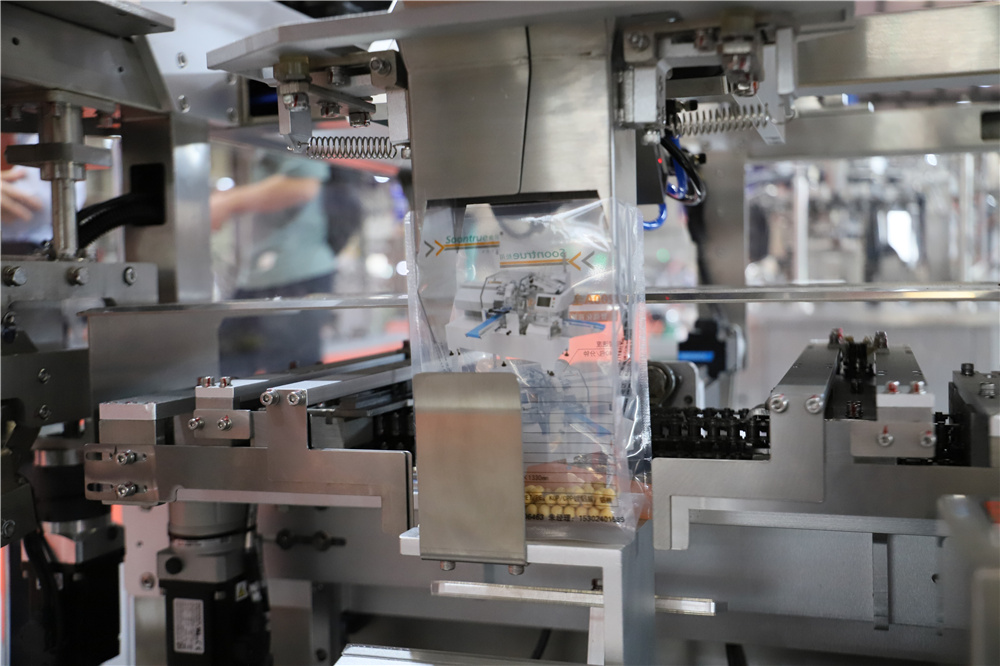

The TD200L is a Vertical Premade Pouch Packing Machine engineered specifically for granule and particulate food products. Unlike horizontal pouch machines designed for large or irregular items, the TD200L uses a vertical pouch handling system combined with weighing and dosing units to ensure accurate filling and minimal product loss.

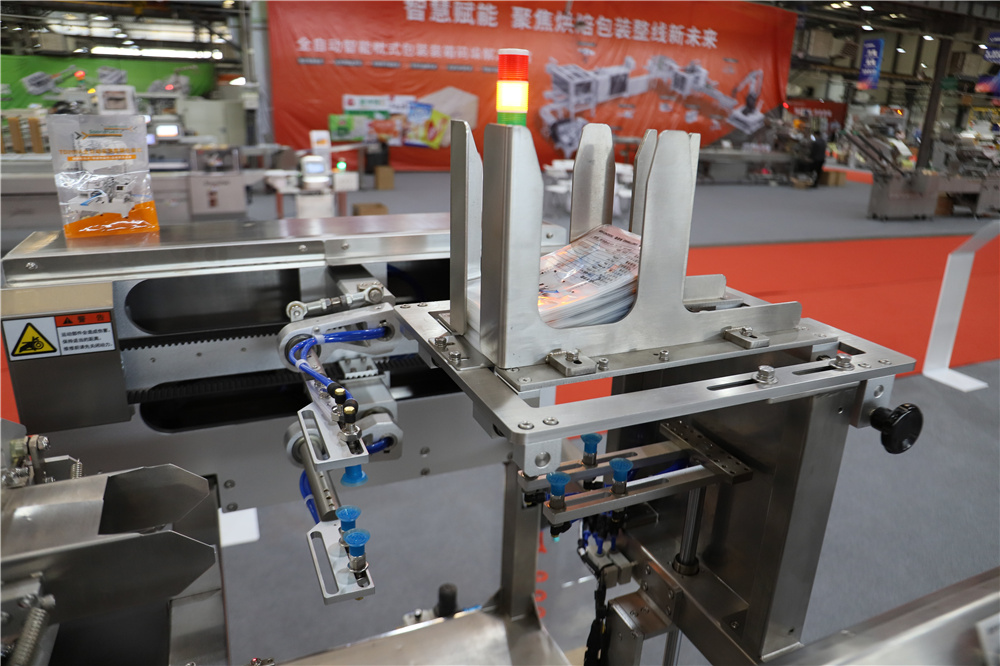

It supports a wide range of premade pouch formats, including stand-up pouches, gusset bags, and zipper pouches, making it suitable for retail-ready food packaging. With its servo-driven controls, fast changeover system, and compact design, the TD200L delivers both efficiency and reliability for granule product manufacturers.

Machine Parameters

| Specifications | TD200L |

| Pouch length | 150-250 mm |

| Pouch width | 50-150 mm |

| Pouch height | 40-100 mm |

| Packing speed | 10-40 pouches/min |

| General power | 8.0 Kw |

| Power supply | 220V/1Ph/50Hz |

| Machine weight | 650 kg |

| Machine dimensions | 1420x988x1500 mm |

| Packing material |

OPP/CPP, PT/PE, aluminum film, KOP/CPP aluminum laminated film |

📌 Reference: Internal test data by Soontrue R&D Lab (2024)

Key Features

- Vertical Premade Pouch Packaging: The TD200L is specifically designed for vertical pouch filling and sealing, allowing it to handle a variety of premade pouch styles, such as stand-up pouches, flat pouches, and more. Its vertical design offers superior space efficiency, perfect for high-speed packaging lines.

- High-Speed and Precision: Equipped with advanced servo motor control, the TD200L ensures high-speed operation while maintaining precise pouch positioning. This results in consistent and reliable packaging performance, reducing waste and downtime.

- Adaptable for Various Products: This machine is suitable for packaging a wide range of products, including powders, granules, and pastes. Whether you're packaging food products, chemicals, or other consumer goods, the TD200L is equipped to handle diverse product types with ease.

- Flexible and Customizable: The TD200L can be easily adjusted to accommodate various pouch sizes, making it a highly flexible option for manufacturers.

- User-Friendly Interface: The machine is equipped with an intuitive touch-screen interface, making it easy for operators to set parameters, monitor production, and adjust settings in real time. This user-friendly design reduces the learning curve and increases operational efficiency.

- Robust and Hygienic Construction: Built with stainless steel, the TD200L ensures a durable and easy-to-clean machine body, making it ideal for industries requiring high hygiene standards, such as food and pharmaceuticals.

Application

The TD200L is engineered as a specialized granule pouch packaging machine, perfect for creating attractive, retail-ready products. Its vertical filling system is optimized for free-flowing items, making it the premier choice for rice packaging, nut packaging, and bagging high-value products like coffee beans, seeds, and premium snacks. By ensuring gentle handling and precise dosing into premade stand-up pouches, this machine helps your brand stand out on the shelf.

Bag Type

A key advantage of the TD200L is its flexibility to handle a wide variety of premade pouches. This includes popular formats like stand-up pouches for excellent shelf presence, zipper resealable bags for consumer convenience, and traditional flat or gusseted pouches. This versatility allows you to adapt your packaging to different market demands and enhance your brand's appeal without needing multiple machines.

Competitive Advantage

- Specialized for Granules, Not a Generalist

Unlike all-in-one machines, the TD200L features a granule-specific design. Its integration with multi-head weighers and volumetric fillers ensures high dosing accuracy, which minimizes product giveaway and directly improves your cost control.

- Mastery of Premade Pouches for Premium Appeal

Leverage the superior look and feel of premade bags. This machine is a master of handling stand-up and zipper pouches, providing the retail-ready packaging that modern consumers demand. This gives you a significant advantage over products packed in simple VFFS bags.

- Rapid Changeover for High-Mix Production

Maximize your uptime with tool-less adjustments for different pouch sizes. This feature drastically reduces downtime between production runs, making the TD200L an ideal investment for businesses with multiple SKUs or those needing to react quickly to market trends.

Why Choose Soontrue?

Soontrue has decades of expertise in granule packaging solutions, delivering machines that combine accuracy, stability, and efficiency. The TD200L Vertical Premade Pouch Packing Machine provides a reliable solution for rice, beans, nuts, sugar, and other granular foods, helping buyers achieve attractive retail-ready packaging with consistent quality. With global support and proven engineering, Soontrue ensures long-term performance and faster ROI.

FAQ - TD200L Vertical Premade Pouch Packing Machine

Q1: What types of products can the TD200L pack?

A1: The TD200L is specialized for granular foods such as rice, beans, nuts, seeds, sugar, salt, and small snacks. Its design ensures smooth handling of free-flowing particles as well as slightly irregular granules like roasted nuts or dried fruits without clogging or spillage.

Q2: How does the machine ensure accurate filling for granules?

A2: The TD200L integrates with multi-head weighers, volumetric cups, or auger fillers depending on the product type. For example, high-value nuts or dried fruits can use a multi-head weigher for maximum precision, while rice and sugar can rely on volumetric systems for fast, consistent output.

Q3: Can it run different pouch formats?

A3: Yes. The TD200L supports a variety of premade pouches, including stand-up pouches, zipper resealable bags, gusset bags, and flat pouches. Buyers can easily switch formats to match different retail or bulk packaging needs.

Q4: How does it minimize product loss or waste?

A4: Its vertical pouch feeding system keeps bags stable during filling, while anti-spill controls and precise dosing reduce giveaway. This results in cost savings over time compared with machines that lack granule-optimized filling.

Q5: Is the machine suitable for fragile products like coated nuts or puffed snacks?

A5: Yes. The system uses gentle filling methods to minimize breakage and protect product integrity, ensuring the packaged goods remain visually appealing for retail.

Q6: How easy is it to operate and maintain?

A6: The TD200L comes with a touchscreen HMI and user-friendly settings for pouch size, filling weight, and sealing temperature. Tool-less changeovers and modular parts make it easy for operators to switch between products. Maintenance is simplified with stainless steel construction and easy-clean contact surfaces.

Q7: What is the typical production speed?

A7: Depending on pouch size and product type, the TD200L can reach up to 40 pouches per minute, maintaining balance between speed and filling accuracy for granular products.

Q8: Does Soontrue provide installation and training support?

A8: Yes. Soontrue offers on-site installation, operator training, and remote technical support, ensuring a smooth start-up and long-term reliable operation.