Automatic Rice Rollers and Similar Products Packaging Line

Automatic Packaging Line Typical Applications

- Rice Rollers & Rice-Based Snacks: Traditional rice rolls, sticky rice snacks

- Egg Rolls & Wafer Rolls: Crisp egg rolls, wafer sticks, cream-filled rolls

- Snack Bars: Chocolate bars, cereal bars, nougat bars

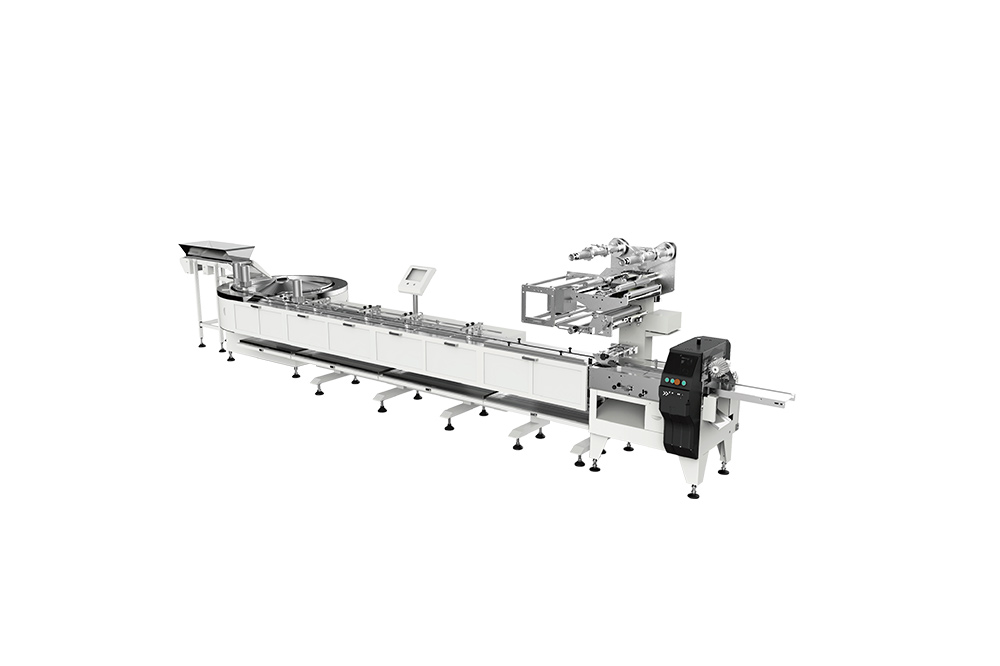

The Automatic Rice Rollers and Similar Products Packaging Line is a dedicated solution for handling fragile, cylindrical, and roll-shaped products. Unlike general-purpose packaging systems, it is designed to ensure gentle feeding, precise alignment, and flexible stacking, making it ideal for products such as egg rolls, wafer sticks, rice rolls, and snack bars.

This line supports both single-layer and dual-layer packaging, including perfectly aligned double layers and non-aligned patterns such as 4+5 formations, which are often required for family packs. This unique flexibility makes the system especially valuable for manufacturers who need to handle delicate items while still meeting high-volume demands.

How It Works

1. Product Feeding

- Products are fed by vibrating feeders or rotary feeders for smooth, controlled entry into the line.

- Feeding design minimizes collisions and reduces breakage of fragile rolls.

2. Sorting & Aligning

- Conveyors and guides channel products into straight rows for consistent packaging.

3. Counting & Grouping

- Servo counters ensure precise product quantities for each pack (e.g., 8 rolls, 10 rolls, 20 rolls).

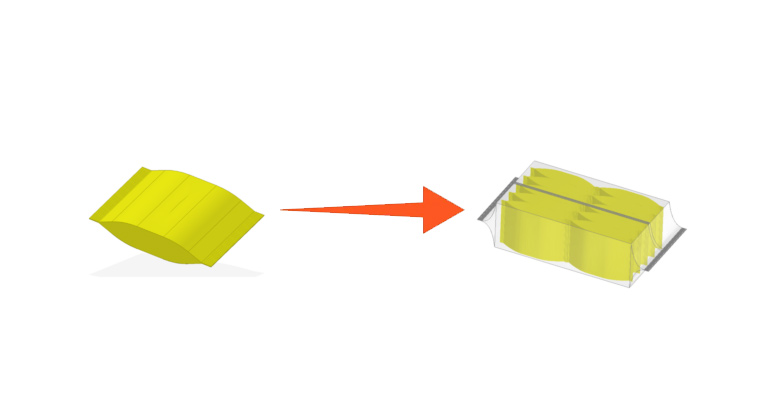

4. Stacking & Layering

- Products can be packed in aligned double layers for neatness, or in non-aligned double layers such as 4+5 formations for efficient use of packaging space.

- This adaptability is a key highlight of the system.

5. Primary Packaging

- Products are packed in pillow packs, trays, or cartons.

- Tight sealing preserves freshness and prevents contamination.

6 .Secondary Packaging (Optional)

- Packed units can be automatically loaded into retail cartons, display boxes, or cases for wholesale.

👉 Core Value: This line ensures gentle handling, precise arrangement, and flexible stacking formats, solving the challenge of packaging fragile roll-shaped products without compromising speed.

Machine Parameters

Key Features

- Accurate Counting: Servo-driven grouping guarantees precise pack quantities

- Flexible Stacking: Supports aligned double layers and unique staggered formations like 4+5

- Versatile Packaging – Suitable for pillow bags, trays, and cartons

- Food-Safe Design – Stainless steel construction for hygienic production

- Customized handling for delicate products: The packaging line is designed to handle fragile products like rice rollers with care, minimizing breakage or damage during the process.

- Flexible packaging formats: Capable of packaging single-piece products as well as multi-piece configurations, whether individually wrapped or grouped together in a family pack.

- High-speed and precise operation: Ensures rapid packaging while maintaining the quality and uniformity of the product, allowing for high-volume production.

- Multi-layer and single-layer packaging: Suitable for stacking products in multiple layers, providing flexibility based on product size and packaging needs.

- Gentle material handling system: Equipped with special conveyors and gripping systems to maintain the shape and texture of delicate rice rollers and similar products.

Application

Bag Type

Competitive Advantage

Many packaging lines struggle with fragile roll-shaped products, leading to breakage or inconsistent stacking. Soontrue's solution addresses this by combining gentle product feeding (vibration + rotary) with smart stacking technology capable of handling both aligned double layers and non-aligned staggered formations like 4+5. This flexibility not only reduces manual adjustment but also allows manufacturers to offer different pack formats without changing equipment. Compared with traditional systems, Soontrue's line achieves higher speed, lower breakage, and better adaptability, making it a superior choice for snack and bakery producers.

Why Choose Soontrue?

With over 30 years of experience in packaging automation, Soontrue understands the unique challenges of fragile product packaging. Our rice roller packaging line integrates cutting-edge servo control, precise counting, and versatile stacking to deliver reliable performance at scale. Backed by a global service network, responsive technical support, and proven engineering expertise, Soontrue provides more than just machines—we provide confidence and long-term partnership. Choosing Soontrue means your products reach the market in perfect condition, every time.

FAQ About Automatic Rice Rollers and Similar Products Packaging Line

Q1: Can the line handle fragile rolls without breaking them?

Yes. Gentle feeding systems (vibrating or rotary) are designed specifically for fragile items.

Q2: What stacking patterns are supported?

The line supports both aligned double layers and non-aligned formats like 4+5, depending on customer needs.

Q3: Can the line handle both single and multi-layer packs?

Yes. It can package individual rolls, single layers, or family-size dual layers.

Q4: Is changeover between formats easy?

Yes. Quick adjustments allow fast switching between single, double, or staggered layouts.

Q5: What industries benefit from this line?

Food industries producing egg rolls, wafer sticks, rice rolls, snack bars, and frozen spring rolls.