ZL180P Vertical Packaging Machine

ZL180P Vertical Packaging Machine Typical Applications

Granular products (rice, nuts, beans)

Powdered products (flour, milk powder, spices)

Snacks & confectionery (chips, candy, dried fruits)

Frozen food (dumplings, vegetables, seafood)

Non-food items (detergent powder, desiccants)

The ZL180P Vertical Packaging Machine is a high-speed VFFS solution designed for 100 bags per minute output, making it ideal for manufacturers seeking both efficiency and flexibility in medium-to-large-scale production. Unlike ultra-high-speed models that are tailored for continuous mass output, the ZL180P strikes a balance between speed, precision, and adaptability, allowing it to handle a wide range of bag sizes and materials with ease.

Equipped with advanced servo-driven controls and an intelligent touch-screen interface, the machine ensures stable sealing quality and quick format changeovers, minimizing downtime and increasing productivity. Its modular design makes it highly adaptable for different industries, including snacks, grains, powders, and liquids, while still maintaining a compact footprint for factories with limited space.

In short, the ZL180P is built for companies who need reliable high-speed performance without compromising on versatility.

Machine Parameters

| Specifications | ZL-180P | ZL-180PH(high speed) | ZL-200P | ZL-200PH(high speed) | ZL-300P |

| Bagging size range | L50-190 mm | L50-190 mm | L 50-300 mm | L50-300 mm | L80-400 mm |

| W50-150 mm | W50-150 mm | W90-200 mm | W90-200 mm | W200-295 mm | |

| Packing fim width | 100-320 mm | 100-320 mm | 200-420 mm | 200-420 mm | 420-620 mm |

| Packing speed | 20-100 bags/min | 20-100 bags/min | 20-90 bags/min | 20-120 bags/min | 15-60 bags/min |

| General power | 3.9 Kw | 4.65 Kw | 3.9 Kw | 4.9 Kw | 4.65 Kw |

| Power supply | 220V/1Ph/50Hz | 220V/1Ph/50Hz | 220V/1Ph/50Hz | 220V/1Ph/50Hz | 220V/1Ph/50Hz |

| Machine weight | 220kg | 250kg | 240 kg | 280 kg | 600 kg |

| Machine dimensions | 1112x1170x1460 mm | 1200x1170x1460 mm | 1300×1170x1582 mm | 1427×1170x1562 mm | 1620×1380x1680 mm |

| End Sealing | Open-close motion | Continuous motion | Open-close motion | Continuous motion | Open-close motion |

| Packing material |

PP,CPP,PVC,PS,EVA,PET,PVDC+PVC,OPP/CPP,etd. |

||||

| View Machine | View Machine | View Machine | View Machine | ||

📌 Reference: Internal test data by Soontrue R&D Lab (2024)

Key Features

High-Speed Output: Capable of running up to 100 bags per minute, ideal for medium-to-large production facilities.

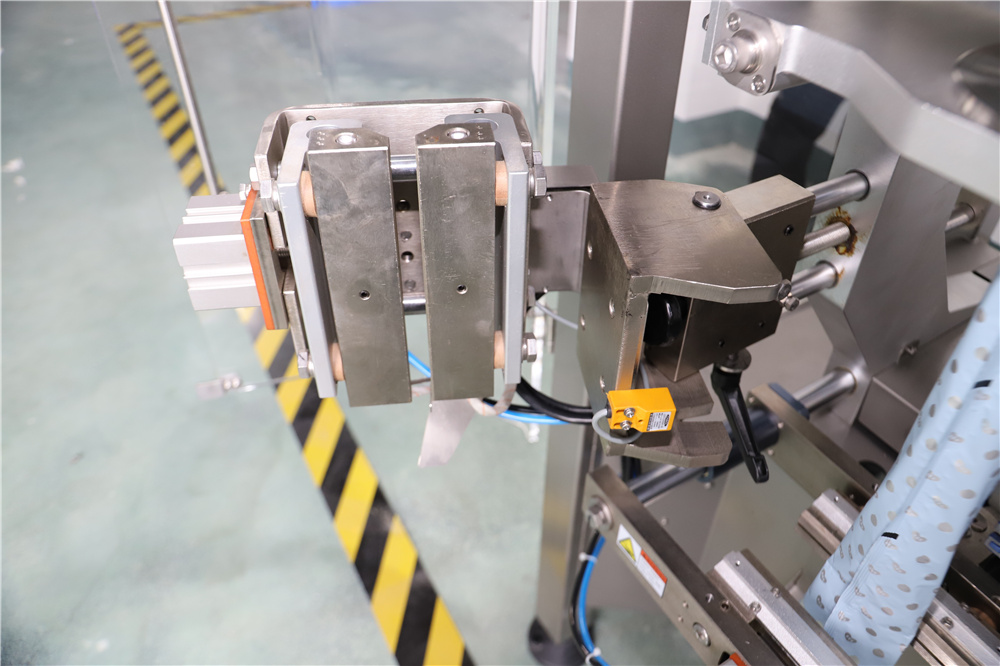

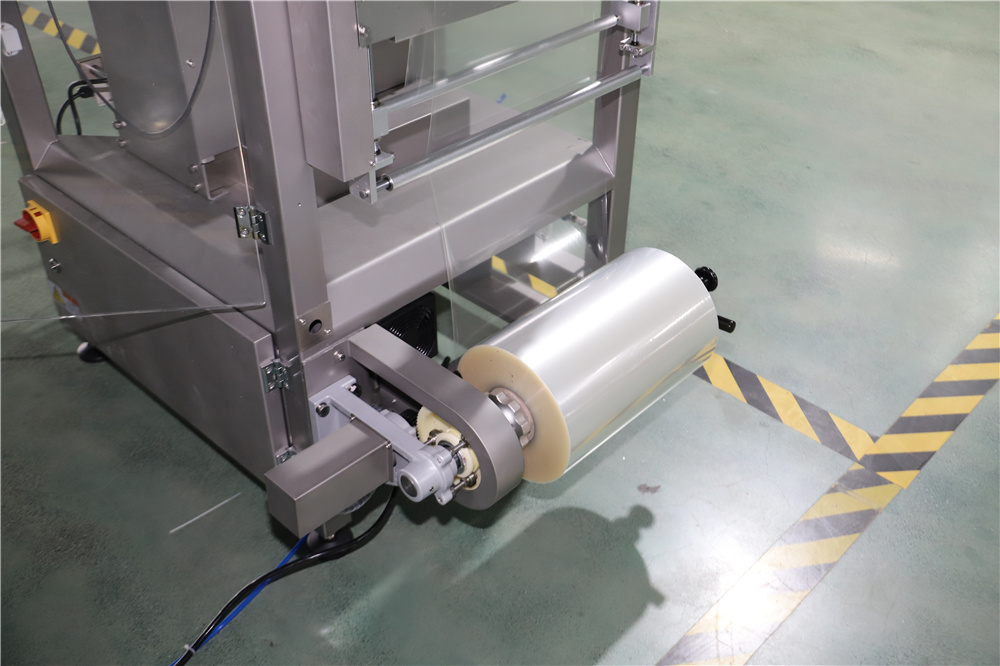

Stable Film Feeding: Advanced servo-driven pulling system ensures precise film handling and reduces film waste.

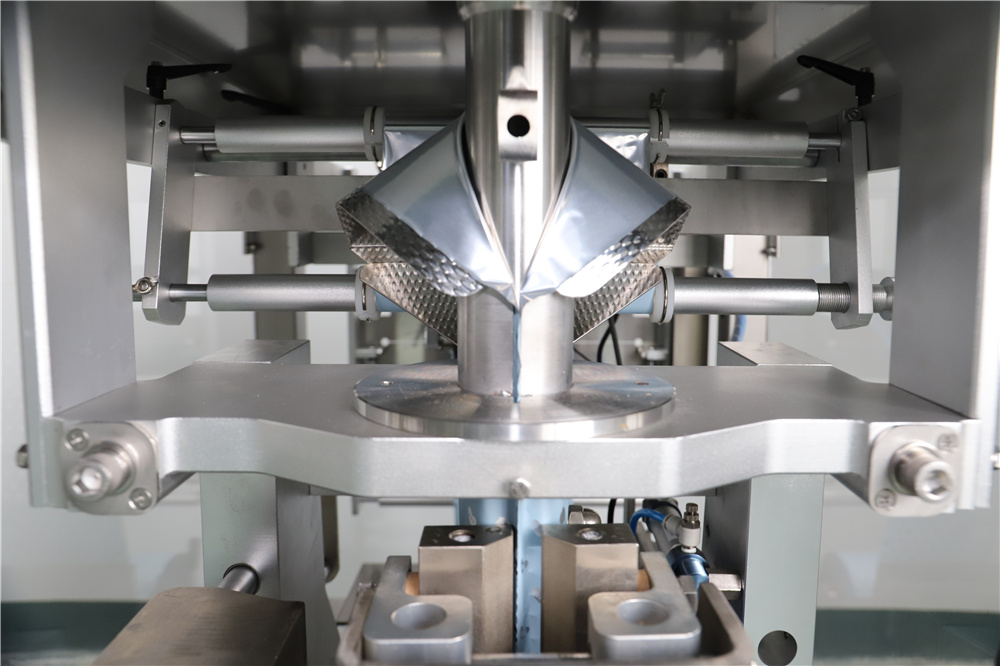

Flexible Bag Formats: Compatible with pillow bags, gusset bags, and flat-bottom bags to meet diverse packaging needs.

User-Friendly Interface: Equipped with an intuitive touchscreen HMI for quick adjustments and recipe changeovers.

Accurate Weighing Integration: Seamlessly works with multihead weighers, auger fillers, and volumetric cup fillers for different product types.

Compact Footprint: Designed to maximize production space efficiency while maintaining robust performance.

Application

The ZL180P stands out as a highly versatile vertical food packaging machine, engineered to handle a diverse range of products across multiple industries. Whether you need a reliable snack food packaging machine for chips and nuts, or a precise VFFS solution for powder packaging like spices and milk powder, the ZL180P delivers with exceptional accuracy. Its adaptability makes it the ideal automatic packaging machine for granules (sugar, salt, coffee beans), frozen foods (dumplings, vegetables), and even non-food items. Explore the common applications below to see how this powerful vertical bagging machine can elevate your production line.

-

Biscuit & Cookie Packaging Solutions

-

Candy Packaging Solutions

-

Chocolate Packaging Solutions

-

Dried Fruits Packaging Solutions

-

Frozen Food Packaging Solutions

-

Nuts Packaging Solutions

-

Oil Packaging Solutions

-

Coffee Powder Packaging Solutions

-

Puffed Food Packaging Solutions

-

Detergent Powder Packaging Solutions

-

Seasoning Powder Packaging Solutions

-

Pet Food Packaging Solutions

-

Rice & Cereal Packaging Solutions

-

Sugar & Salt Packaging Solutions

-

Medical Supplies Sterile Packaging Solutions

-

Personal Care Liquid Packaging Solutions

-

Sauce Packaging Solutions

-

Beverage Packaging Solutions

-

Secondary Packaging (Random Bag Packaging Solutions)

Bag Type

Competitive Advantage

- Superior Speed: While many entry-level vertical bagging machines operate at 70-80 bags/min, the ZL180P consistently achieves 100 bags/min, making it a top-tier automatic packaging machine for growing production demands.

- Advanced Film Saving: Unlike many alternatives, our VFFS machine features a servo-driven film pulling system. This technology minimizes film waste, directly lowering the operational cost of your food packaging line compared to machines with less precise controls.

- Stronger Seal Integrity: Critical for freshness and safety, the ZL180P is engineered for robust seals. This vertical machine for food packaging utilizes enhanced pressure and temperature controls to significantly reduce the leakage issues common in lower-end models.

- Greater Application Versatility: The ZL180P is more than just a single-purpose machine. It's a comprehensive powder and granule packaging machine that also expertly handles snacks, frozen foods, and even small hardware, making it a flexible asset for diverse product portfolios.

- Simplified Maintenance: We designed this vertical packaging machine for maximum uptime. Its modular construction and quick-change parts simplify maintenance, giving you a distinct advantage over traditional machines that require lengthy service downtime.

- Compact, Powerful Footprint: Get high-speed performance without sacrificing floor space. This vertical form fill seal machine offers a significantly smaller footprint than competitor models with similar output, making it easy to integrate into existing production lines.

Why Choose Soontrue?

Choose Soontrue for a partner that blends 30+ years of VFFS engineering with global service and fast parts support. For the ZL180P, we focus on what matters in real factories: 100 bags/min stable output, a compact footprint that fits existing lines, and seamless integration with multi-head weighers, auger or volumetric cup fillers, and downstream automation. Our machines use servo motion, smart HMI recipes, and quick-change tooling to cut changeover time and reduce film waste—lowering total cost of ownership versus many competitor models. Built with food-grade stainless steel and easy-clean access, the ZL180P supports HACCP/GMP workflows while our team provides on-site commissioning, operator training, remote diagnostics, and tailored bag/forming sets for your SKUs. In short, Soontrue delivers the performance, reliability, and ROI you need—backed by responsive experts who keep your line running.

FAQ-What is ZL180P Vertical Packaging Machine?

Q1: Is the ZL180P more suitable for medium or large production runs?

A1: The ZL180P is optimized for medium-to-large scale operations with speeds up to 100 bags/min. It’s ideal for manufacturers who need high efficiency but don’t necessarily require ultra-high-speed models.

Q2: Can the ZL180P handle both food and non-food applications?

A2: Yes. It is widely used for snacks, grains, powders, frozen food, as well as non-food products like detergents and chemicals. Its flexible dosing integration makes it suitable for multiple industries.

Q3: How much space does the ZL180P require compared to larger machines?

A3: The ZL180P features a compact footprint, which saves 15–20% more floor space compared to larger vertical packaging machines with similar performance.

Q4: How easy is it to switch between different bag sizes?

A4: Thanks to its servo-driven controls and modular forming sets, changeovers are fast and simple, often taking just a few minutes without special tools.