Automatic Packaging Line With Deoxidizer

Versatile Packaging Solution for Diverse Products

Baked Goods: Bread, cakes, mooncakes, cookies

Snacks & Nuts: Chips, peanuts, dried fruits, trail mixes

Meat & Protein Products: Jerky, sausages, vacuum-sealed meat

Ready-to-Eat & Preserved Foods: Rice meals, pickled vegetables, preserved seafood

Other Oxygen-Sensitive Products: Coffee, tea, traditional delicacies

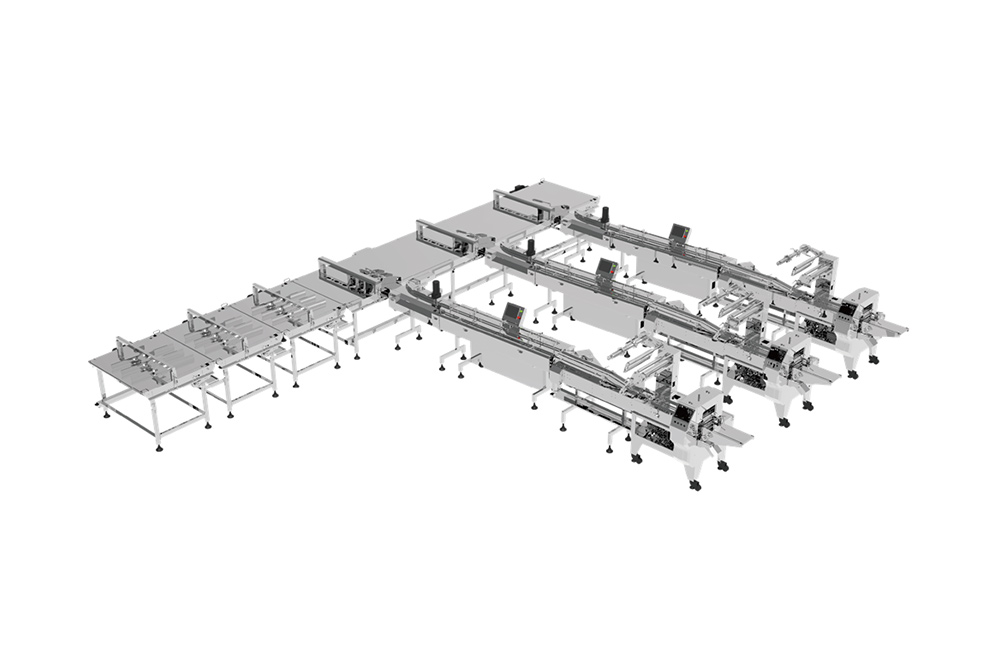

An Automatic Packaging Line with Deoxidizer is a specialized packaging system designed to integrate deoxidizer sachet dispensing into the packaging process. Unlike standard packaging lines, it not only sorts and packs products but also ensures that each package contains a precisely placed deoxidizer sachet, creating a low-oxygen environment that extends shelf life and preserves product quality.

How It Works

1. Product Feeding & Sorting

- Products are automatically aligned using conveyors and feeding systems.

- Items such as bread, cookies, or meat snacks are positioned correctly for packaging.

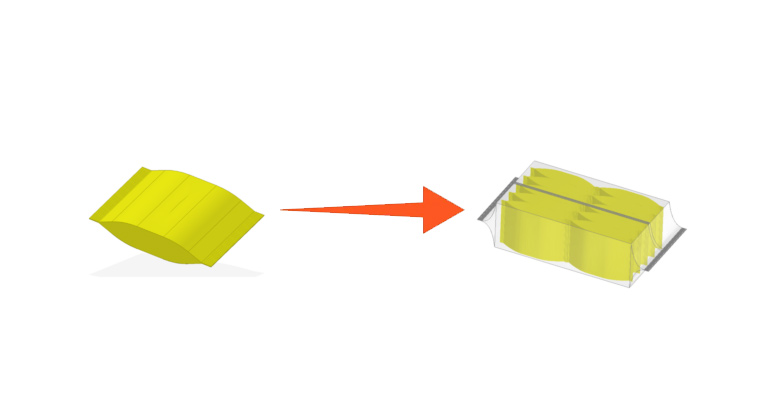

2. Deoxidizer Dispensing

- A high-precision sachet dispenser inserts one deoxidizer into each package.

- Advanced sensors prevent errors such as double-sachet placement or missed sachets.

3. Sealing & Oxygen Control

- The packaging machine (flow wrapper, VFFS, or pouch machine) seals the product.

- Special sealing ensures minimal oxygen remains inside, preventing oxidation and spoilage.

4. Final Output

- Products are discharged in ready-to-ship form, with extended freshness, improved safety, and consistent quality.

👉 Core Value: By combining packaging and deoxidizer insertion, this line eliminates manual handling, reduces human error, and guarantees product preservation for industries with strict quality standards.

Machine Parameters

Key Features

- Integrated Sachet Dispensing – Ensures accurate placement of deoxidizer in each pack

- High Precision & Reliability – Sensors detect missing or double sachets to avoid waste and risk

- Flexible Packaging Compatibility – Works with pillow packs, stand-up pouches, and vacuum bags

- Customizable Configuration – Designed to match your product, speed, and packaging format

- Food-Grade Design – Hygienic materials and easy-clean structure for safe food packaging

- Efficiency Boost – Maintains high-speed output while preserving quality

Application

Bag Type

Competitive Advantage

Compared with traditional suppliers who still rely on manual or semi-automatic methods, Soontrue's automatic packaging line with deoxidizer stands out for its accuracy, speed, and flexibility. Our system integrates high-precision sachet placement with intelligent error-detection sensors, ensuring that every package receives the correct deoxidizer without slowing down production. While many competitors offer only standardized solutions, Soontrue provides tailor-made designs adapted to different product types, sachet sizes, and packaging styles. Backed by advanced servo control and IoT-enabled monitoring, our lines guarantee consistent quality and efficiency. Combined with our global service network and proven expertise, this makes Soontrue the trusted partner for food manufacturers seeking to extend product shelf life and maintain strict quality control.

Why Choose Soontrue?

With over 30 years of experience in packaging automation, Soontrue has earned its reputation as a trusted partner for global food manufacturers. What sets us apart is our ability to design tailor-made solutions that perfectly match each customer's production layout, packaging style, and speed requirements. From consultation and engineering design to manufacturing, installation, and training, we provide a one-stop service that ensures smooth implementation and long-term reliability. Our commitment to continuous innovation—including servo control, IoT monitoring, and AI-based quality checks—keeps your production future-ready, while our global service network guarantees responsive after-sales support wherever you are. Choosing Soontrue means choosing a partner who combines technical expertise, proven reliability, and world-class service to help your business grow with confidence.

FAQ About Automatic Packaging Line With Deoxidizer

Q1: Can the machine adapt to different deoxidizer sizes?

Yes. The dispenser is adjustable and can be configured to match different sachet sizes and weights.

Q2: Will adding deoxidizers reduce production speed?

No. Our system integrates sachet dispensing without slowing down the packaging line.

Q3: What types of packaging are supported?

It is compatible with pillow packs, pouches, trays, and vacuum-sealed bags.

Q4: Is maintenance difficult?

No. The dispenser is designed for easy cleaning and quick adjustments, ensuring minimal downtime.

Q5: Does the system meet international food safety standards?

Yes. All equipment is built with food-grade materials and complies with CE, UL, and other global standards.