SW60X Horizontal Flow Wrapping Machine

SW60X Horizontal Flow Wrapping Machine Typical Applications

- Bakery & Confectionery: biscuits, cookies, petite cakes, chocolate bars, waffles

- Snacks & Convenience Foods: instant noodle blocks, energy bars, frozen dumplings, small bread rolls

- Household & Daily Products: pocket tissues, wet wipes, disposable tableware, sanitary goods

- Industrial & Hardware: small tools, fittings, electronic accessories, hardware kits

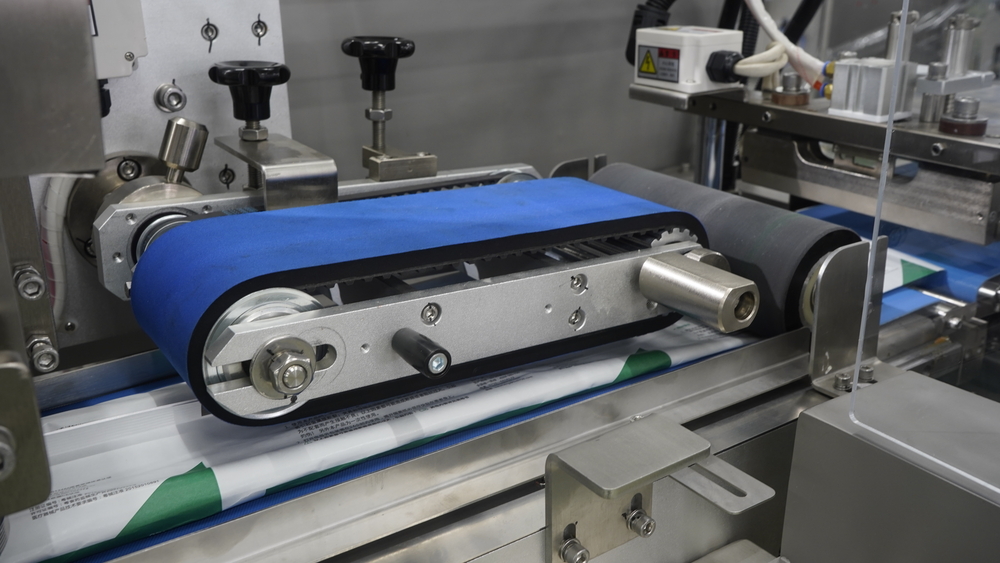

The SW60X Horizontal Flow Wrapping Machine is a compact, servo-driven solution designed for stable and efficient packaging of small-to-medium products across food, household, and light industrial sectors. Unlike entry-level wrappers, it employs a bottom-film feeding system, keeping products firmly positioned on the infeed conveyor. This design minimizes misalignment, particularly when handling soft, heavy, or irregularly shaped goods such as bakery rolls, frozen dumplings, or hardware kits.

The SW60X also integrates a box-motion end sealing system, which delivers longer sealing dwell time than rotary sealing. This ensures strong, airtight, and visually consistent seals, even with thicker or multi-layer films often used for extended shelf life. Controlled entirely by multi-servo motors, the SW60X guarantees accurate film pulling, precise registration, and minimal material waste.

Compact yet powerful, this model is ideal for manufacturers who require industrial-grade sealing performance in a space-saving machine, and it can be easily integrated with upstream feeders, printers, metal detectors, and downstream case packers for full-line automation.

Machine Parameters

| Specifications | SW60X | SW80X | SZ280XW | SZ750XW | SZ801w |

| Bagging size range | L90-450 mm | L90-450 mm | L120-600 mm | L120-600 mm | L150-600 mm |

| Product size rgnge | W10-180 mm | W35-200 mm | W70-200 mm | W150-330 mm | W70-350 mm |

| H 5-60 mm | H 5-80 mm | H 5-80 mm | H 5-80 mm | H 60-130 mm | |

| Packing speed | 30-120 bags/min | 30-100 bags/min | 25-60 bags/min | 25-60 bags/min | 20-50 bags/min |

| Packing fim width | 90-420 mm | 90-500 mm | 200-600 mm | 300-750 mm | MAX. 900 mm |

| Power supply | 220V/1Ph/50Hz | 220V/1Ph/50Hz | 220V/1Ph/50Hz | 220V/1Ph/50Hz | 220V/1Ph/50Hz |

| General power | 8.0 KW | 8.0 KW | 6.6 KW | 7.6 KW | 8.6 KW |

| Machine weight | 730 kg | 750 kg | 775 kg | 800 kg | 850 kg |

| Machine dimensions | 4820x1065x1450 mm | 5100x1100x1500 mm | 4330x1130x 1410 mm | 4325x1325x1410 mm | 2800x1320x1610 mm |

| Packing material | PP,PVC,PS,EVA,PET,PVDC+PVC,OPP+CPP etc. | ||||

| View Machine | View Machine | View Machine | View Machine | ||

📌 Reference: Internal test data by Soontrue R&D Lab (2024)

Key Features

- Bottom-Film Feeding:Keeps products stable; reduces skew, scuffing, and rewraps on soft/irregular items.

- Box-Motion End Sealing:Long dwell for strong, airtight seals on tough or multilayer films.

- Full-Servo Control:Accurate film pull and sealing timing; consistent bag length and print mark tracking.

- Compact Footprint:Industrial sealing performance in a smaller frame—easy to fit on existing lines.

- Fast Size Changeovers:Tool-assisted adjustments with recipe storage on touchscreen HMI.

- Hygienic Build:Stainless frame, smooth surfaces, optional washdown modules.

- Options-Ready:Gas flush, hole/euro-slot punch, tear notch, static eliminator, printers/labelers, MD/CW integration.

Application

-

Bread & Bakery Packaging Solution

-

Organized Bag Secondary Packaging Solutions

-

Chocolate Packaging Solutions

-

Frozen Food Packaging Solutions

-

Meat Poultry & Seafood Packaging Solutions

-

Noodle Packing Solutions

-

Vegetable & Fruit Packaging Solutions

-

Hardware Packaging Solutions

-

Household & Hotel Goods Packaging Solutions

-

Medical Supplies Sterile Packaging Solutions

Bag Type

Competitive Advantage

Compared to conventional horizontal wrappers, the SW60X stands out by combining compact design with premium sealing technology:

- Product Stability:Bottom-film feeding ensures smoother wrapping of delicate or heavy products, where top-film machines may struggle.

- Seal Integrity:Box-motion sealing provide stronger and more reliable seals than standard rotary sealers, reducing rejects and rewraps.

- Precision & Waste Reduction:Servo-driven control minimizes film waste and guarantees consistent bag length and appearance.

- Flexibility:Supports multiple bag formats (pillow bags, gusseted bags, euro-slot) and can handle diverse packaging films, from OPP/CPP laminates to recyclable PE-based films.

- Compact Efficiency:Delivers the sealing quality of larger machines but in a footprint that fits smaller workshops or multi-SKU cells.

For buyers, these differences mean greater reliability, fewer product losses, reduced downtime, and a faster return on investment compared to entry-level or purely mechanical flow wrappers.

Why Choose Soontrue?

Choosing the SW60X Horizontal Flow Wrapping Machine also means choosing Soontrue as a long-term packaging partner. With over 30 years of engineering expertise, Soontrue has installed thousands of horizontal flow wrappers worldwide, supporting industries from bakery to medical supplies.

Soontrue offers more than machines—we provide:

Global Support & Training:Installation, spare parts, and local service teams.

Full-Line Integration:Expertise in combining flow wrappers with feeders, printers, inspection devices, and palletizing systems.

Customization:Flexible bag formats, film options, and modules like gas-flush, tear-notch, or remote monitoring.

Reliability & ROI:Machines designed for 24/7 operation, reducing waste, downtime, and overall packaging cost.

This combination of engineering reliability, after-sales service, and scalable integration makes Soontrue not just a machine vendor, but a trusted partner helping manufacturers achieve efficiency and long-term growth.

FAQ - SW60X Horizontal Flow Wrapping Machine

Q1: What kinds of products fit the SW60X best?

Solid, individual or small bundle items—no powders/liquids—including bakery pieces, bars, wipes, and small hardware.

Q2: Why bottom-film feeding instead of top-film?

Bottom-film supports the product during wrapping, improving alignment and finish on soft/heavy/irregular goods.

Q3: What’s the difference between box-motion and rotary sealing?

Box-motion travels with the film to provide longer seal time, yielding stronger end seals than rotary sealing on many films.

Q4: Can it integrate with inspection and coding?

Yes—common integrations include inkjet/TTO printers, labelers, metal detectors, checkweighers, and upstream feeders.

Q5: What films and bag styles are supported?

Typical OPP/CPP, PET/PE, PE-based structures; pillow bags, optional gusset/euro-slot/tear notch, plus gas-flush if needed.

Q6: Is it suitable for food contact environments?

The stainless-steel structure and optional washdown packages support hygienic operation (specify your compliance needs).