ZL180PH High-Speed Vertical Packaging Machine

ZL180PH High-Speed Vertical Packaging Machine Typical Applications

- Powder products (milk powder, flour, coffee powder, spices)

- Granules (rice, nuts, beans, sugar, salt)

- Small solid items (candies, snacks, seeds)

- Liquids & pastes (sauces, condiments, dairy, shampoo, lotions)

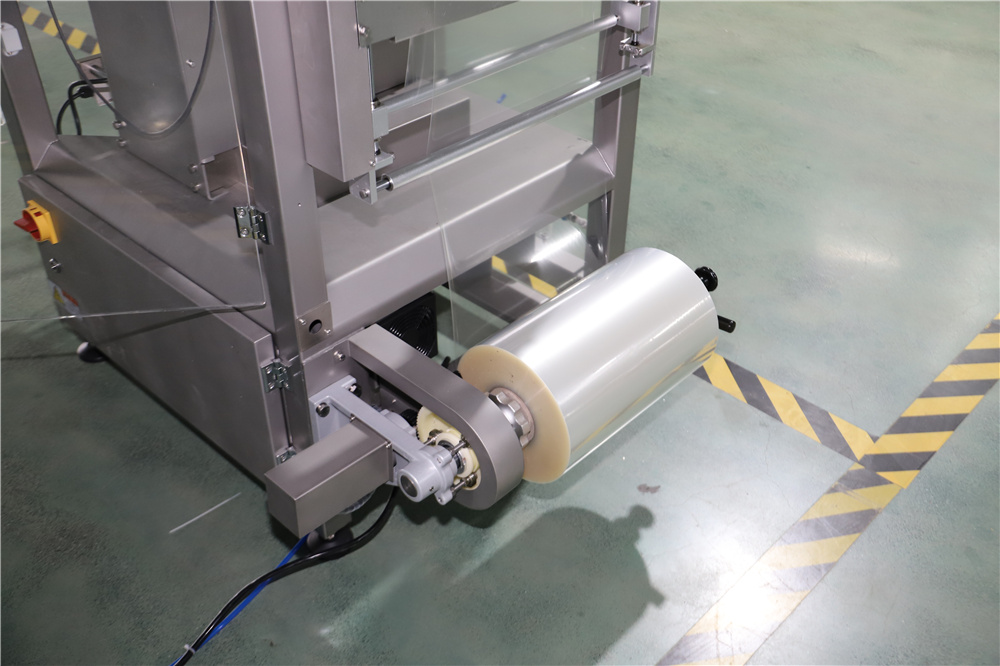

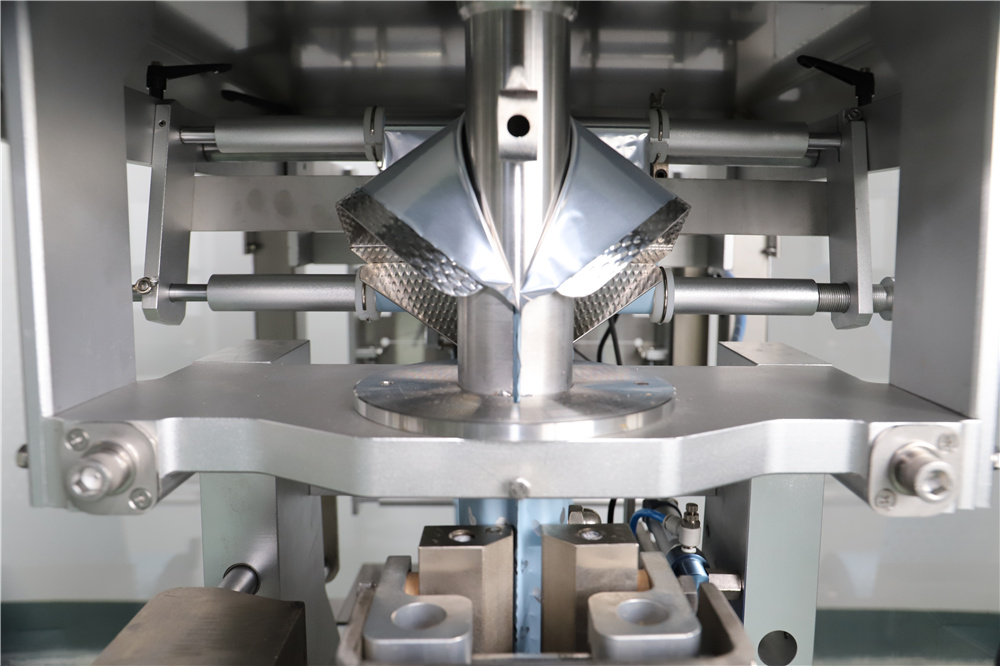

The ZL180PH High-Speed Vertical Packaging Machine is an advanced VFFS (Vertical Form Fill Seal) solution designed for flexible packaging across powders, granules, liquids, and small solid products. Equipped with servo-driven film pulling and intelligent sealing technology, it ensures stable performance even at high operating speeds. Its modular design allows integration with weighing systems such as multihead weighers, volumetric cup fillers, and liquid pumps, giving manufacturers the flexibility to adapt to different product requirements.

This machine is engineered for industries demanding both speed and accuracy, such as food, beverages, pharmaceuticals, and chemicals. With user-friendly controls, compact footprint, and reliable sealing quality, the ZL180PH provides an efficient packaging solution that maximizes output while minimizing downtime. Its precision and adaptability make it an excellent choice for businesses looking to scale their production capacity while maintaining consistent product quality.

Machine Parameters

| Specifications | ZL-180P | ZL-180PH(high speed) | ZL-200P | ZL-200PH(high speed) | ZL-270 |

| Bagging size range | L50-190 mm | L50-190 mm | L 50-300 mm | L50-300 mm | L120-350 mm |

| W50-150 mm | W50-150 mm | W90-200 mm | W90-200 mm | W100-265 mm | |

| Packing fim width | 100-320 mm | 100-320 mm | 200-420 mm | 200-420 mm | 225-555 mm |

| Packing speed | 20-100 bags/min | 20-120 bags/min | 20-90 bags/min | 20-120 bags/min | 15-70 bags/min |

| General power | 3.9 Kw | 4.65 Kw | 3.9 Kw | 4.9 Kw | 4.0 Kw |

| Power supply | 220V/1Ph/50Hz | 220V/1Ph/50Hz | 220V/1Ph/50Hz | 220V/1Ph/50Hz | 220V/1Ph/50Hz |

| Machine weight | 220kg | 250kg | 240 kg | 280 kg | 600 kg |

| Machine dimensions | 1112x1170x1460 mm | 1200x1170x1460 mm | 1300×1170x1582 mm | 1427×1170x1562 mm | 1795×1139x1568 mm |

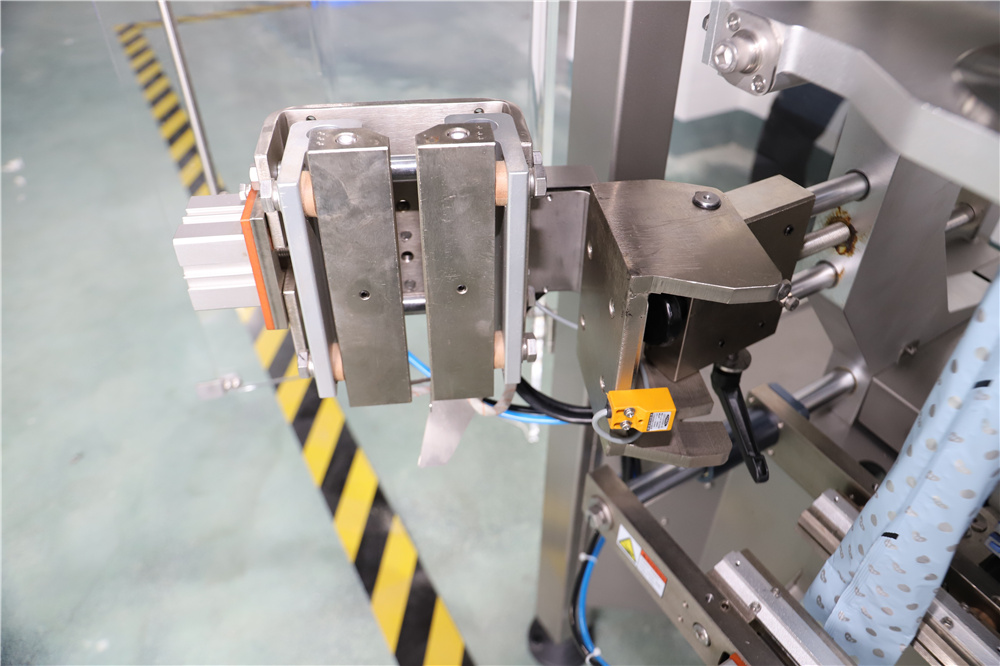

| End Sealing | Open-close motion | Continuous motion | Open-close motion | Continuous motion | Open-close motion |

| Packing material |

PP,CPP,PVC,PS,EVA,PET,PVDC+PVC,OPP/CPP,etd. |

||||

| View Machine | View Machine | View Machine | |||

📌 Reference: Internal test data by Soontrue R&D Lab (2024)

Key Features

High-Speed Packaging: Engineered for continuous, stable operation at higher speeds, ideal for mass production.

Advanced Servo Control: Ensures precise film pulling and consistent sealing accuracy.

Compact Footprint: Space-saving vertical design without compromising efficiency.

Flexible Integration: Works seamlessly with multihead weighers, volumetric fillers, and liquid pumps.

Reliable Sealing Quality: Optimized sealing system to handle powders, granules, and small solids at high speed.

User-Friendly HMI: Touchscreen interface for quick setup, real-time monitoring, and easy recipe changeover.

Application

Master Diverse Products: From Powder to Liquids

Your search for a versatile automatic packing machine ends here. The ZL180PH is not just for standard powders; it excels in challenging applications. Whether you need a hygienic sauce packaging machine for liquid sachets, solution for powder food packaging, or high-speed bagging for nuts and sugar, this system adapts instantly. Its servo-driven technology ensures precise handling of liquids, granules, and solids alike.

-

Biscuit & Cookie Packaging Solutions

-

Candy Packaging Solutions

-

Chocolate Packaging Solutions

-

Dried Fruits Packaging Solutions

-

Frozen Food Packaging Solutions

-

Nuts Packaging Solutions

-

Oil Packaging Solutions

-

Coffee Powder Packaging Solutions

-

Puffed Food Packaging Solutions

-

Detergent Powder Packaging Solutions

-

Seasoning Powder Packaging Solutions

-

Pet Food Packaging Solutions

-

Rice & Cereal Packaging Solutions

-

Sugar & Salt Packaging Solutions

-

Medical Supplies Sterile Packaging Solutions

-

Personal Care Liquid Packaging Solutions

-

Sauce Packaging Solutions

-

Beverage Packaging Solutions

-

Secondary Packaging (Random Bag Packaging Solutions)

Bag Type

Flawless Bag Formation at High Speeds

Achieving consistent seal quality on a high-speed vertical packaging machine can be challenging, but the ZL180PH makes it effortless. Whether producing Pillow Bags for cereal or high-barrier sachets for sauces, our advanced sealing jaws ensure airtight integrity without compromising speed. This guarantees your product looks professional and stays fresh, from the factory floor to the consumer's hand.

Competitive Advantage

- Higher Packing Speed (Up to 120 BPM)

The ZL180PH achieves a remarkable speed of up to 120 bags/min, performing significantly faster than many competitor models in the same range. This high-speed capability ensures maximum output for mass production needs.

- More Stable Sealing Quality

Equipped with advanced temperature control, the machine ensures consistent and airtight seal quality, even during continuous high-speed runs. This reliability prevents leakage and protects product freshness better than standard sealing systems.

- Flexible Material Compatibility

While many peers require separate machines for different products, the ZL180PH handles powders, granules, and liquids on a single unit. Its modular dosing units allow for seamless switching between product types, offering superior versatility.

- Reduced Changeover Time

Featuring a tool-free changeover design, this machine cuts downtime significantly compared to traditional competitor machines. Operators can adjust settings or switch bag sizes quickly without the need for complex manual tools.

- Intelligent Servo System

Unlike competitor models that rely on single-motor drives, the ZL180PH utilizes multi-servo synchronization. This provides smoother motion, higher precision, and greater stability during operation.

Why choose Soontrue?

Since 1993, Soontrue has been a trusted global packaging machinery manufacturer, offering advanced automation solutions across food, chemical, and personal care industries. The ZL180PH reflects our dedication to efficiency, innovation, and customer success. With strong R&D, fast delivery, and reliable after-sales service, Soontrue ensures every customer benefits from both performance and long-term value.

FAQ - ZL180PH High-Speed Vertical Packaging Machine

Q1: How is the ZL180PH different from other VFFS machines on the market?

A1: Unlike many standard VFFS models limited to powders or granules, the ZL180PH supports multiple dosing systems (screw, volumetric cup, liquid pump), making it versatile for powders, granules, and liquids. It also achieves higher speed with more stable sealing.

Q2: Can the ZL180PH reduce changeover downtime compared to competitors?

A2: Yes. Thanks to its tool-free modular design, changeover between products or bag sizes takes minutes, while many competitor models require 30–60 minutes of manual adjustments.

Q3: Is it suitable for high-precision packaging where seal integrity is critical?

A3: Absolutely. The ZL180PH integrates multi-servo motion control and smart temperature regulation. This ensures precise film pulling and consistent seals, outperforming competitor machines that rely on single-motor or less advanced controls.

Q4: How does Soontrue support overseas buyers differently from local suppliers?

A4: Soontrue provides global after-sales service with remote diagnostics, spare parts centers, and multilingual training. Many local competitors only provide limited remote support or slow parts delivery.

Q5: What about cost of ownership compared with similar machines?

A5: While the upfront investment is competitive, the ZL180PH has lower long-term costs due to its energy-efficient design, reduced maintenance needs, and extended component life.

Q6: Can it integrate with secondary packaging or automated lines?

A6: Yes. The ZL180PH is designed for seamless integration with Soontrue’s case erectors, cartoners, and palletizers, which gives you a one-stop automated packaging solution — a level of integration many competitors lack.