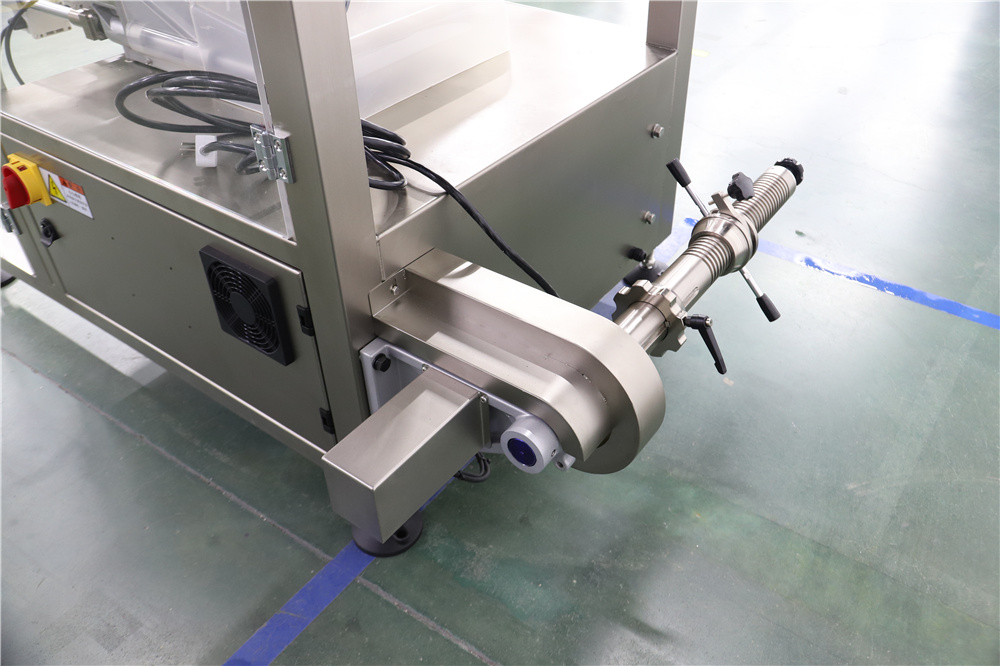

ZL200P Vertical Packaging Machine

ZL200P Vertical Packaging Machine Typical Applications

- Granules (rice, nuts, beans, sugar, salt)

- Powders (flour, milk powder, spices, chemicals)

- Liquids & pastes (sauces, condiments, dairy, shampoo, detergents)

- Snacks (chips, candies, small baked items)

The Soontrue ZL200P is a highly versatile and fully automated vertical packaging machine, engineered as a comprehensive VFFS (Vertical Form-Fill-Seal) solution. It is specifically designed to be a reliable food packaging machine for small to medium-sized enterprises.

Whether you need a precise powder filling machine for spices, a high-performance granule packing machine for nuts and snacks, or a clean liquid bagging machine for sauces, the ZL200P provides an all-in-one system. By integrating film pulling, bag forming, product dosing, and sealing into one compact and hygienic unit, it helps you increase production efficiency, reduce labor costs, and ensure consistent package quality.

Machine Parameters

| Specifications | ZL-200P | ZL-200PH(high speed) | ZL-270 | ZL-300P | ZL-350 |

| Bagging size range | L 50-300 mm | L50-300 mm | L120-350 mm | L80-400 mm | L100-500 mm |

| W90-200 mm | W90-200 mm | W100-265 mm | W200-295 mm | W175-350 mm | |

| Packing fim width | 200-420 mm | 200-420 mm | 225-555 mm | 420-620 mm | 375-725 mm |

| Packing speed | 20-90 bags/min | 20-120 bags/min | 15-70 bags/min | 15-60 bags/min | 5-45 bags/min |

| General power | 3.9 Kw | 4.9 Kw | 4.0 Kw | 4.65 Kw | 5.8Kw |

| Power supply | 220V/1Ph/50Hz | 220V/1Ph/50Hz | 220V/1Ph/50Hz | 220V/1Ph/50Hz | 220V/1Ph/50Hz |

| Machine weight | 240 kg | 280 kg | 600 kg | 600 kg | 980 kg |

| Machine dimensions | 1300×1170x1582 mm | 1427×1170x1562 mm | 1795×1139x1568 mm | 1620×1380x1680 mm | 2200x1500x2090 mm |

| End Sealing | Open-close motion | Continuous motion | Open-close motion | Open-close motion | Open-close motion |

| Packing material |

PP,CPP,PVC,PS,EVA,PET,PVDC+PVC,OPP/CPP,etd. |

Laminated film | |||

| View Machine | View Machine | View Machine | |||

📌 Reference: Internal test data by Soontrue R&D Lab (2024)

Key Features

- Flexible dosing systems for powders, granules, and liquids

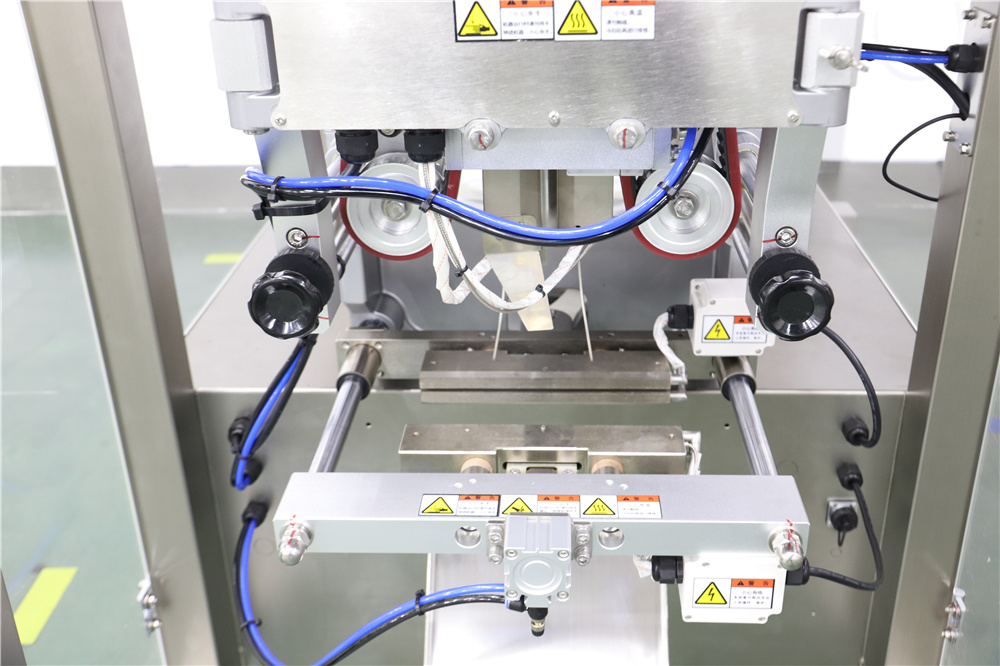

- Servo-driven motion control for precise sealing and stable film pulling

- Compact footprint for easy integration in production lines

- Multi-bag style support including pillow, gusset, and flat-bottom bags

- Easy changeovers with quick-adjust forming sets

- Hygienic design with stainless steel structure, easy to clean

Application

The ZL200P is engineered for flexibility, making it an ideal food packaging machine for diverse products. Whether you need a high-precision powder filling machine for spices and flour, a reliable granule packing machine for snacks and coffee beans, or a sanitary liquid bagging solution for sauces and detergents, the ZL200P adapts to your needs. Its quick-changeover design allows you to switch between different products with minimal downtime.

-

Biscuit & Cookie Packaging Solutions

-

Candy Packaging Solutions

-

Chocolate Packaging Solutions

-

Dried Fruits Packaging Solutions

-

Frozen Food Packaging Solutions

-

Nuts Packaging Solutions

-

Oil Packaging Solutions

-

Coffee Powder Packaging Solutions

-

Puffed Food Packaging Solutions

-

Detergent Powder Packaging Solutions

-

Seasoning Powder Packaging Solutions

-

Pet Food Packaging Solutions

-

Rice & Cereal Packaging Solutions

-

Sugar & Salt Packaging Solutions

-

Medical Supplies Sterile Packaging Solutions

-

Personal Care Liquid Packaging Solutions

-

Sauce Packaging Solutions

-

Beverage Packaging Solutions

-

Secondary Packaging (Random Bag Packaging Solutions)

Bag Type

The ZL200P primarily produces the pillow bag, the most cost-effective and common bag style. However, its supports a wide range of bag styles, including gusset bags, flat-bottom bags, and multi-layer laminated film pouches, this capability makes our vertical bagging machine a versatile asset for your branding needs.

Competitive Advantage

- Efficiency and Speed: With speeds up to 90 bags/min, the ZL200P significantly boosts your production throughput, lowering your cost-per-package compared to standard models.

- Stronger Sealing Quality: High-precision servo sealing system ensures fewer leakages and rejects versus standard pneumatic systems.

- Seamless Line Integration: Designed as a core component of an automated packaging solution, the ZL200P integrates flawlessly with upstream weighers and downstream cartoners, creating a truly automated production line.

- Built for Durability: Constructed with a heavy-duty stainless steel frame and high-quality components, this machine is engineered for a long service life and reduced maintenance, ensuring a higher return on investment.

Why choocse Soontrue

Choosing Soontrue means partnering with a manufacturer that combines over three decades of packaging innovation with a global support network. Our vertical form fill seal machines are engineered with precision, ensuring higher efficiency, longer durability, and easier operation than most alternatives in the market. We don’t just deliver machines—we provide end-to-end packaging solutions, from design to integration, tailored to your production needs. Backed by reliable after-sales service and a strong reputation across food, chemical, and consumer goods industries, Soontrue is the trusted choice for businesses seeking both performance and peace of mind.

FAQ - ZL200P Vertical Packaging Machine

Q1: Can the ZL200P pack both liquid and powder products without changing tools?

No. Liquids and powders require different dosing systems, so the weighing or filling tool must be changed accordingly. The ZL200P is designed for quick changeovers, allowing you to switch between different dosing units—such as auger fillers for powders and liquid pumps for sauces or condiments—ensuring precise and reliable packaging for each product type.

Q2: What types of bags are compatible with the ZL200P?

The ZL200P supports a wide range of bag styles, including pillow bags, gusset bags, flat-bottom bags, and multi-layer laminated film pouches, making it suitable for diverse packaging needs across industries.

Q3: How easy is it to maintain and clean the machine?

The ZL200P is designed with a hygienic structure and tool-free disassembly of key parts. This makes daily cleaning, maintenance, and replacement of contact components quick and convenient, especially important for food and pharmaceutical applications.

Q4: Does Soontrue provide training and after-sales support?

Yes. Soontrue offers comprehensive operator training, installation guidance, and 24/7 online support. Global service centers and spare parts supply ensure customers receive timely assistance and long-term reliability for their packaging operations.