SZ180 Horizontal Packaging Machine

SZ180 Horizontal Packaging Machine Typical Applications

- Bakery products such as bread, cakes, and croissants

- Confectionery items like candy and chocolate bars

- Daily-use items including small pouches or personal care packs

- Sachet or strip packs for grouped retail display

The Soontrue SZ180 is a best-selling horizontal flow wrapping machine trusted by manufacturers across the food packaging industry. Engineered for medium to high-volume production lines, this pillow packaging solution delivers high-speed, high-precision performance while maintaining the integrity and presentation of your products.

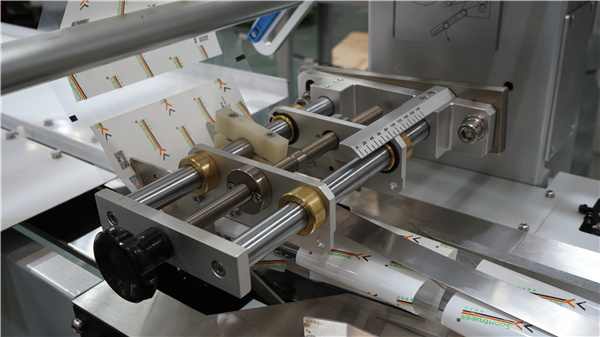

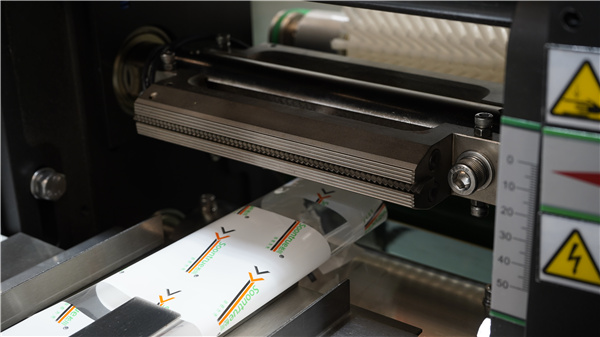

With a servo-control system and rotary end sealing technology, the SZ180 ensures airtight and visually appealing pillow bag — ideal for snacks, baked goods, confectionery, and other fast-moving consumer goods. Its flexible film handling capabilities and adjustable bag sizes make it highly adaptable to a variety of product types and packaging needs.

Whether you're aiming to streamline operations, enhance packaging consistency, or expand product offerings, the SZ180 provides the efficiency, reliability, and versatility needed in a modern packaging line — making it a top choice for both established brands and growing manufacturers.

Machine Parameters

| Specifications | SZ-100 | SZ-180 (double cutter) | SZ-180 (double cutter) | SZ-580 (double cutter) | SZ-580 (triple cutter) |

| Sealing wheels structure | Small | Small | Big | ||

| Bagging size range | L 60-250 mm | L100-350 mm | L100-350 mm | L60-500 mm | L45-300 mm |

| W35-80 mm | W35-160 mm | W35-160 mm | W35-160 mm | W35-80mm | |

| Product size range | H5-35 mm | H 5-50 mm | H 5-50 mm | H 5-60 mm | H 5-30 mm |

| Packing speed | 30-250 bags/min | 30-250 bags/min | 30-300 bags/min | 30-350 bags/min | 30-500 bags/min |

| Packing film width | 90-220 mm | 90-370 mm | 90-370 mm | 90-400 mm | 90-400 mm |

| Power supply | 220V/1Ph/50Hz | 220V/1Ph/50Hz | 220V/1Ph/50Hz | 220V/1Ph/50Hz | 220V/1Ph/50Hz |

| General power | 3.8 KW | 5.3 KW | 6.5 KW | 7.3 KW | 6.6 KW |

| Machine weight | 360 kg | 400 kg | 400 kg | 450 kg | 450 kg |

| Machine dimensions | 4000x930x1370mm | 4000x930x1370mm | 4000x930x1370mm | 4200x970x1640mm | 4200x970x1640mm |

| Packing material | PP, PVC, PS, EVA, PET, PVDC+PVC, OPP/CPP, etd. | ||||

| View Machine | View Machine | View Machine | |||

📌 Reference: Internal test data by Soontrue R&D Lab (2024)

Key Features

- Precision and Reliability: The SZ-180 features servo-control rotary motion end sealing for consistent, airtight seals that protect products from contamination and spoilage. An advanced servo control system ensures reliable and precise performance for every package.

- Versatility in Packaging: With the ability to handle bag widths from 40–100 mm and lengths from 80–300 mm, this machine is highly adaptable to a wide range of product sizes, from small snacks to larger food items. It is compatible with both printed and unprinted film materials.

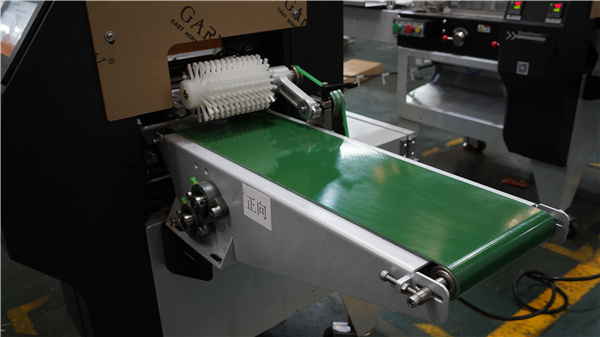

- Ease of Use: The machine is designed for user-friendly operation with a simple interface and tool-free product changeover. Its compact, space-saving design also makes it easy to integrate into existing production lines.

Application

-

Biscuit & Cookie Packaging Solutions

-

Bread & Bakery Packaging Solution

-

Disposable Goods Packaging Solutions

-

Candy Packaging Solutions

-

Chocolate Packaging Solutions

-

Noodle Packing Solutions

-

Hardware Packaging Solutions

-

Household & Hotel Goods Packaging Solutions

-

Medical Supplies Sterile Packaging Solutions

Bag Type

Competitive Advantage

- Soontrue's top-selling flow wrapper worldwide

- Optimized for performance-to-cost ratio — a preferred choice for OEMs and distributors

- Proven long-term reliability in global bakery and snack production lines

- Faster setup and lower film waste compared to conventional models

- Continuous upgrades and support backed by Soontrue R&D teams

Why Choose Soontrue?

With 30+ years of experience in intelligent packaging, Soontrue is globally recognized for durable machinery and responsive service. Our SZ180 model reflects that legacy — delivering high uptime, customizable options, and trusted performance in even the most demanding operations. From installation to lifetime technical support, we ensure every customer receives tailored, value-driven solutions.

FAQ - SZ180 Horizontal Packaging Machine

Q1: What types of film can be used on the SZ180?

The machine is compatible with OPP/CPP, OPP/PE, and other common food-grade laminated films.

Q2: Can it be integrated into an existing production line?

Yes. The compact frame and adjustable feeders allow seamless integration with upstream/downstream equipment.

Q3: Is it suitable for fragile bakery items?

Yes, the machine supports gentle infeed systems ideal for soft or delicate products.

Q4: What is the maintenance requirement?

It requires minimal daily maintenance. Easy-access panels and tool-free adjustments keep downtime low.