Packing Line Solutions for Food Industry and End-of-Line Automation

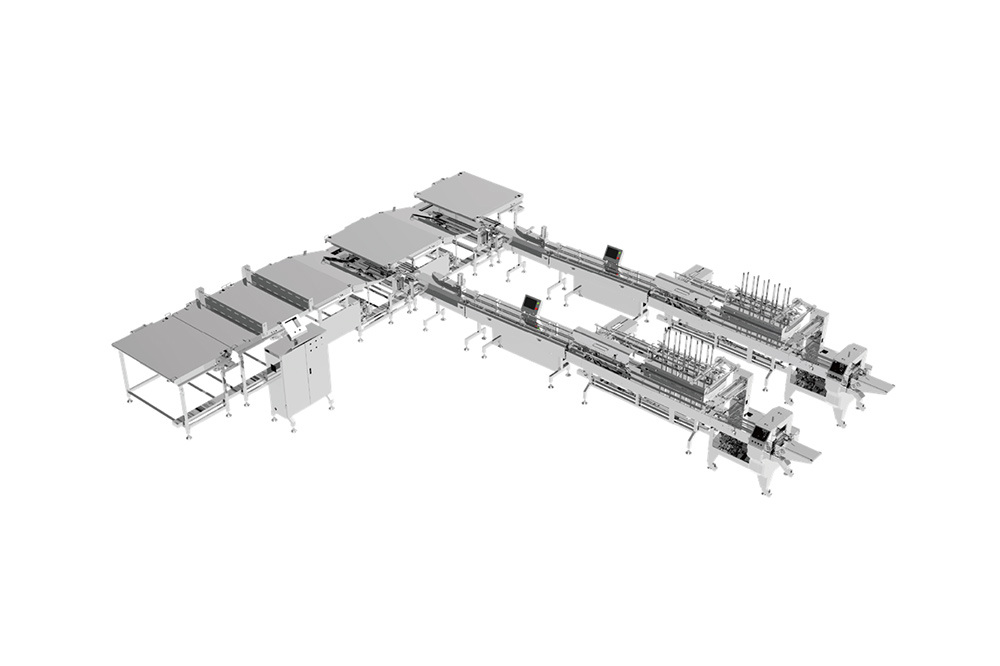

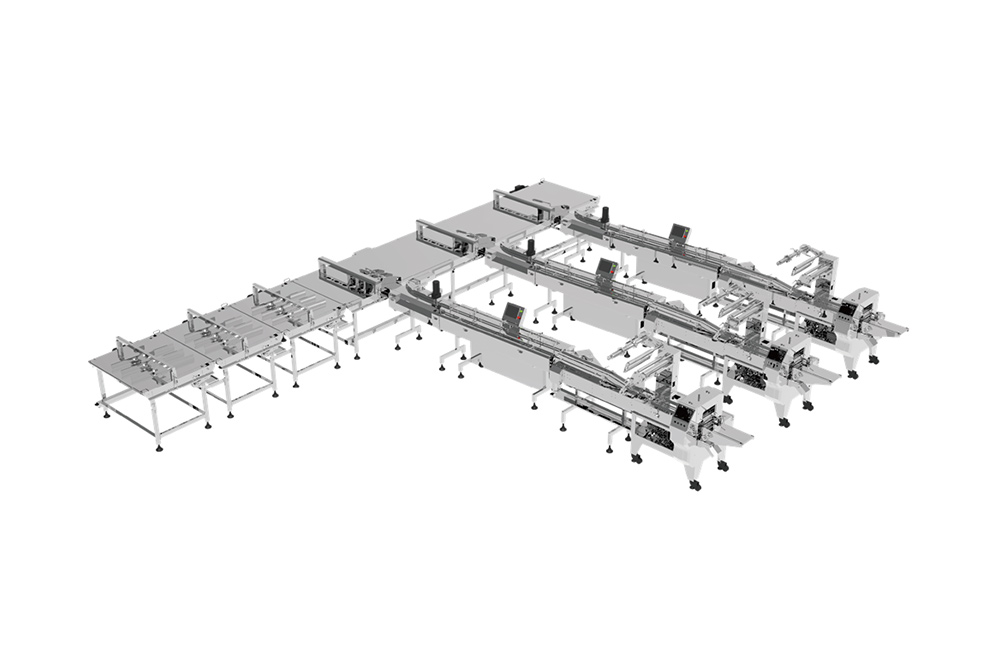

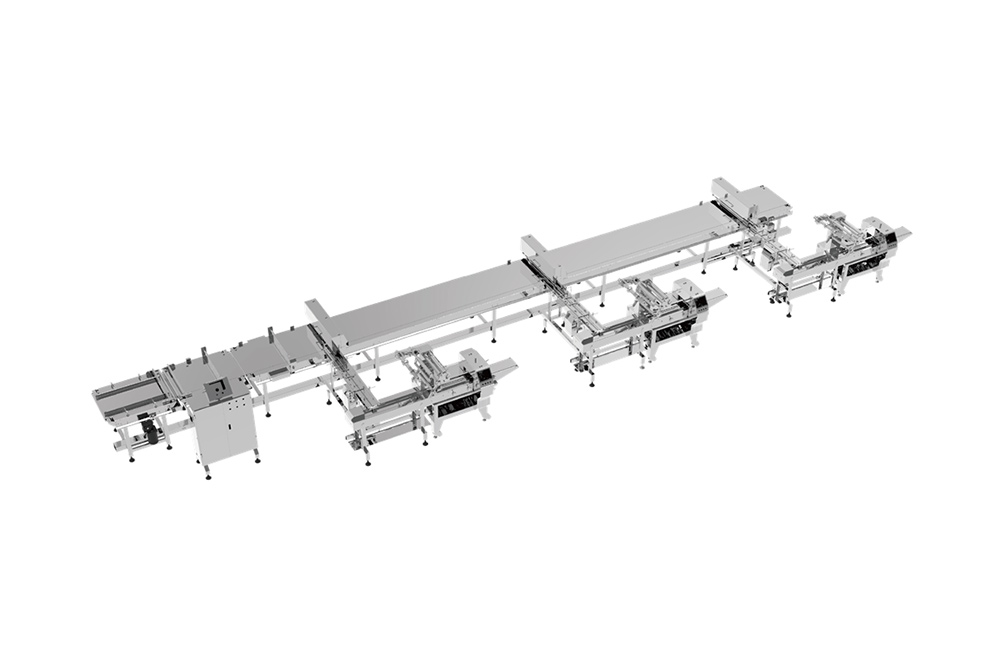

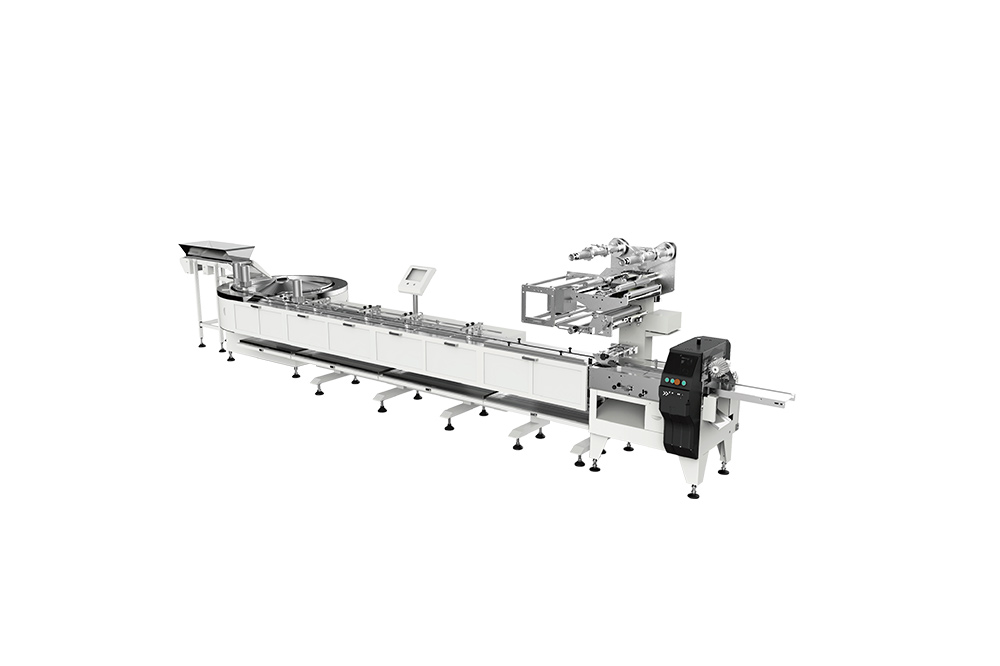

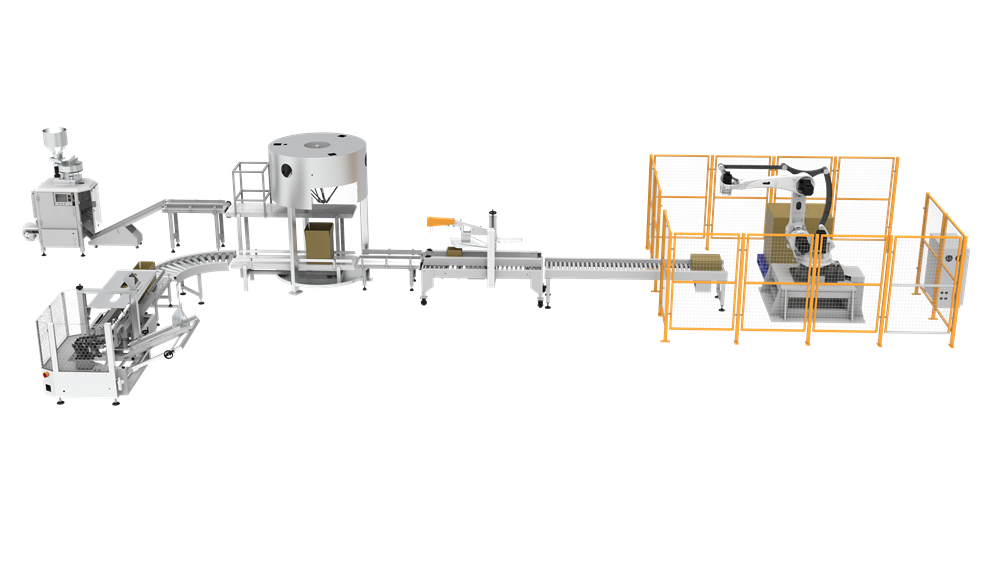

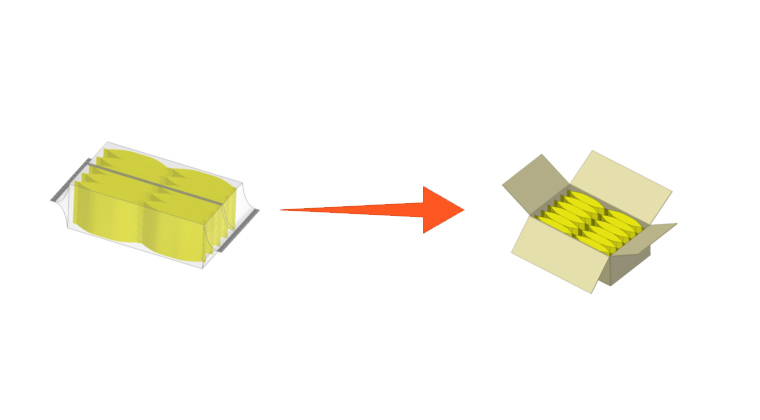

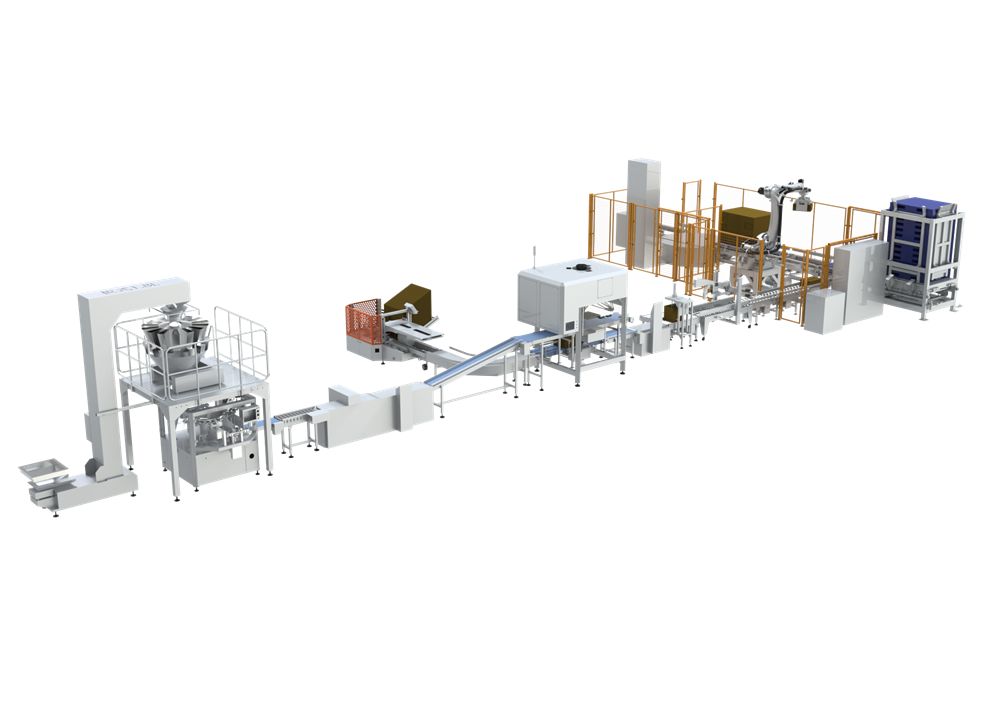

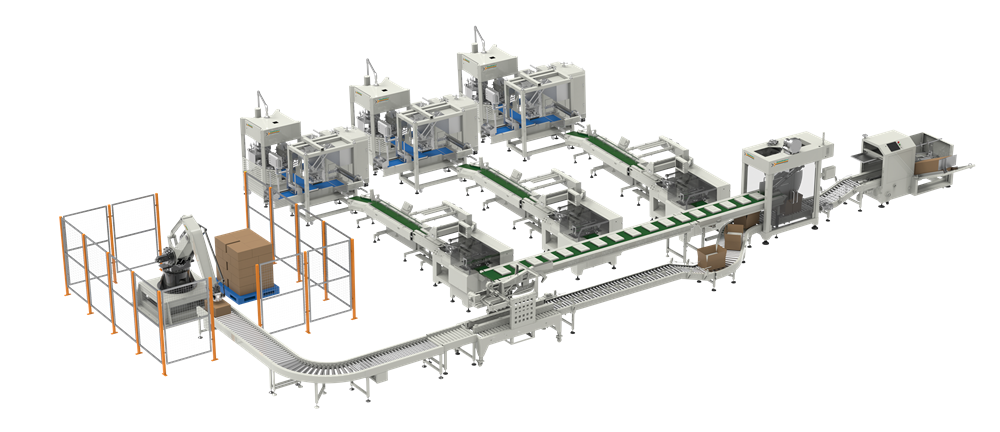

Our packing line solutions are engineered for the food industry and end-of-line packaging automation. Designed to handle everything from product sorting and primary packaging to case packing and palletizing, these systems improve efficiency, ensure hygiene, and reduce manual labor. Whether you're processing frozen foods, baked goods, snacks, or ready meals, our lines can be customized for various product sizes, pack formats, and production speeds.

We specialize in one-stop end-of-line packing lines—integrating case erectors, sealers, robotic case packers, and palletizers into a seamless, automated system. These solutions ensure high-speed, consistent output while minimizing human contact, making them ideal for modern food manufacturers aiming to scale production and meet strict hygiene standards.

Browse our packing line solutions or contact us to discuss your specific food packaging needs.

Why Choose Automatic Packing Lines?

- Increased Efficiency: Automatic packing lines reduce reliance on manual labor and ensure faster packing with fewer errors.

- Customizable for Various Products: From food to consumer goods, these lines can be adapted to handle different product sizes, weights, and types.

- Comprehensive Solutions: One-stop systems cover all stages of the packaging process, including sorting, case packing, and palletizing.

- Enhanced Safety and Hygiene: Automated packing minimizes human contact, ensuring safer and more hygienic packaging, especially for food products.

In conclusion, automatic packing lines, whether focused on food packaging or one-stop solutions, are essential for modern businesses aiming to increase efficiency, reduce costs, and maintain high-quality standards. They are fully customizable to meet specific production needs and provide end-to-end packaging solutions from sorting to palletizing.