GDS210-08 Premade Pouch Packaging Machine

GDS210-08 Premade Pouch Packaging Machine Typical Applications

- Snacks & dry food: chips, nuts, biscuits, cereals.

- Powder products: coffee, protein powder, flour, milk powder.

- Frozen & ready-to-eat food: dumplings, vegetables, seafood.

- Household & personal care: detergent, pet food, daily chemicals.

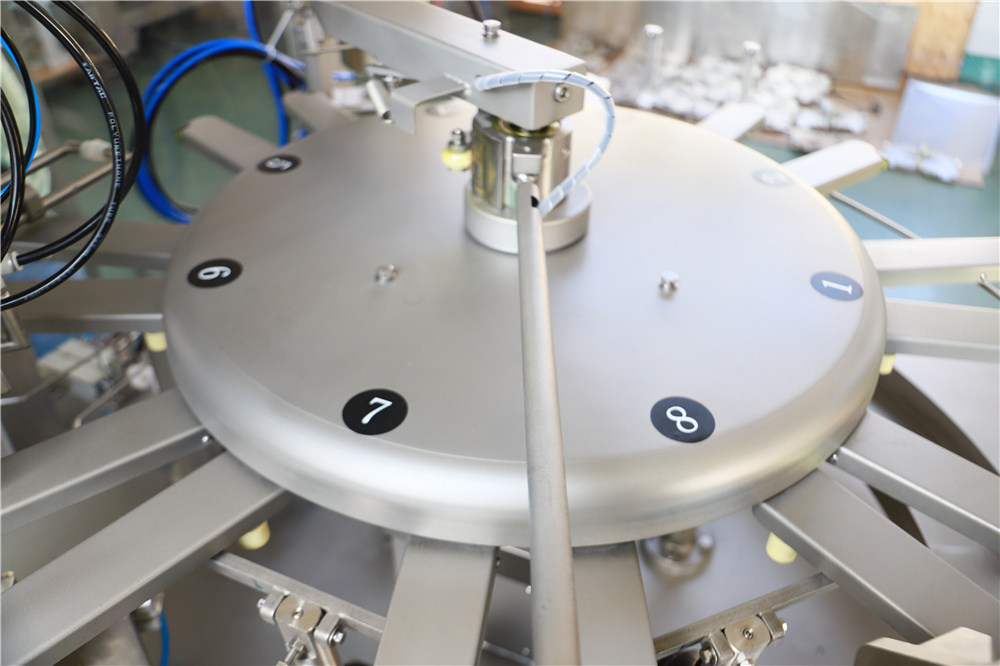

The GDS210-08 is a rotary premade pouch packaging machine with eight working stations, positioned as the standard model in the GDS series. It is designed to deliver a balanced combination of packaging speed, pouch compatibility, and operational stability, making it suitable for a wide range of industries.

Compared with the GDS180-06, which focuses on small pouches and entry-level automation, the GDS210-08 supports a broader pouch size range and achieves higher throughput. In contrast to high-capacity models such as the GDS210-10 or GDS300-08, it provides a more cost-efficient solution while maintaining versatility for mainstream pouch packaging applications.

The GDS210-08 integrates the complete workflow into a single automated cycle:

- Automatic pouch feeding & pick-up – Reliable magazine system ensures consistent bag handling.

- Stable pouch opening – Vacuum and mechanical mechanisms maintain accuracy, even for zipper pouches.

- Flexible filling options – Compatible with multihead weighers for snacks, auger fillers for powders, and liquid pumps for sauces or dairy.

- Accurate sealing & coding – Delivers strong, airtight seals with optional coding or labeling integration.

- Smooth discharge – Finished pouches are efficiently transferred for downstream packing or cartoning.

The GDS210-08 is widely used in snacks, coffee, protein powder, frozen food, pet food, and daily chemical packaging, offering a reliable and versatile automation platform that supports consistent quality and production efficiency.

Machine Parameters

| Specifications | GDS180-06 | GDS210-08 | GDS210-10 | GDS260-08 | GDS300-08 |

| Working stations | 6 | 8 | 10 | 8 | 8 |

| Bagging size range | L ≦360 mm | L 120-380 mm | L 120-380 mm | L ≦400 mm | L 400 mm |

| W 70-180 mm | W80-210 mm | W80-210 mm | W130-260 mm | W160-300 mm | |

| Packing speed | ≦60 pouches/min | ≦70 pouches/min | ≦100 pouches/min | ≦72 pouches/min | ≦72 pouches/min |

| General power | 3.4 Kw | 8.0 Kw | 8.0 Kw | 8.0 Kw | 8.0 Kw |

| Power supply | 380V/3Ph/50Hz | 380V/3Ph/50Hz | 380V/3Ph/50Hz | 380V/3Ph/50Hz | 380V/3Ph/50Hz |

| Machine weight | 400 kg | 500kg | 600 kg | 580 kg | 650 kg |

| Machine dimensions | 1500x900x1460 mm | 1700x1140x1470 mm | 1900×1340x1520 mm | 1850×1250x1520 mm | 2100×1500x1520 mm |

| Premade bag | Flat pouch,stand-up pouch, zipper pouch, top seal pouch, doypack pouch,etc. | ||||

| Packing material |

Single layer PE, PE laminated film, paper film and other laminated film |

||||

| View Machine | View Machine | View Machine | View Machine | ||

📌 Reference: Internal test data by Soontrue R&D Lab (2024)

Key Features

Eight Working Stations for Increased Productivity: With its advanced 8-station rotary design, the GDS210-08 enhances productivity by allowing multiple stages of the packaging process to occur simultaneously. This structure maximizes output, making it perfect for high-volume applications in industries such as food, cosmetics, and pharmaceuticals.

Versatile Packaging Options: The GDS210-08 is compatible with a wide range of pouch types, from flat pouches to stand-up pouches, offering flexibility to businesses with diverse packaging needs. Whether you're looking to package powders, granules, liquids, or solid items, this machine is tailored to adapt to various product types with precision.

Customizable Weighing and Filling Tools: To ensure precise filling, the GDS210-08 can be equipped with optional tools like volumetric cups, augers, multi-head weighers, or liquid pumps, providing accurate and consistent filling for a wide array of products. This addresses concerns about product waste and packaging consistency, crucial for maintaining quality and efficiency.

Rotary Premade Pouch Technology: The GDS210-08’s rotary premade pouch system ensures smooth and continuous operation. This efficient system allows for the quick and seamless handling of pouches, making it an ideal automatic bagging machine for businesses looking to streamline their packaging lines.

Application

-

Biscuit & Cookie Packaging Solutions

-

Candy Packaging Solutions

-

Chocolate Packaging Solutions

-

Dried Fruits Packaging Solutions

-

Frozen Food Packaging Solutions

-

Nuts Packaging Solutions

-

Oil Packaging Solutions

-

Coffee Powder Packaging Solutions

-

Puffed Food Packaging Solutions

-

Detergent Powder Packaging Solutions

-

Seasoning Powder Packaging Solutions

-

Pet Food Packaging Solutions

-

Rice & Cereal Packaging Solutions

-

Sugar & Salt Packaging Solutions

-

Medical Supplies Sterile Packaging Solutions

-

Personal Care Liquid Packaging Solutions

-

Sauce Packaging Solutions

-

Beverage Packaging Solutions

-

Secondary Packaging (Random Bag Packaging Solutions)

Bag Type

Competitive Advantage

- From a buyer's perspective, the GDS210-08 is a cost-effective investment for mainstream packaging needs:

- Versatility across industries: One machine can serve snacks, powders, frozen food, and chemicals, reducing the need for multiple systems.

- Reliable speed: Higher output than entry-level machines, while maintaining consistency for daily production.

- Cost-to-performance ratio: Delivers strong value without the higher price tag of large-format models.

- Market adaptability: Meets the requirements of mid-sized factories looking to expand capacity or upgrade from semi-automation.

- Reduced learning curve: Easier for operators to adapt compared with high-capacity equipment, lowering training costs.

- Compared with other models in the series, the GDS210-08 is the most balanced choice—not as limited as the GDS180-06, and more affordable and practical than the GDS300-08 for buyers who don't require extra-large pouches.

Why Choose Soontrue?

Soontrue delivers reliable automation for real-world manufacturing. The GDS210-08 embodies our commitment to providing buyers with machines that balance cost, performance, and flexibility. With global service support, CE-compliant design, and proven stability in diverse industries, Soontrue ensures every investment translates into lasting efficiency and growth for our clients.

FAQ - GDS210-08 Premade Pouch Packaging Machine

Q1: What makes the GDS210-08 different from the GDS180-06?

A1: The GDS210-08 has eight working stations, faster speed, and handles a wider pouch size range, making it better for mid-scale production.

Q2: Can this machine be used for both food and chemical products?

A2: Yes. With the right filling system, it can pack powders, liquids, granules, and chemicals in premade pouches.

Q3: What is the typical buyer profile for this model?

A3: Mid-sized factories and distributors who need versatile packaging without investing in larger high-capacity machines.

Q4: How fast is the GDS210-08?

A4: Depending on pouch size and product type, it can reach up to 70 bags per minute.

Q5: Does Soontrue provide overseas service?

A5: Yes. Soontrue offers installation, operator training, spare parts, and global after-sales service.