ZL300P Vertical Packaging Machine

ZL300P Vertical Pacaging Machine Typical Applications

- Food

- Liquid

- Powder

- Granular

The ZL300P vertical packaging machine is a robust VFFS machine tailored for larger-format bag packaging with maximum speeds up to 60 packs per minute. While not focused on speed, it excels in handling bulkier powder, granular, or liquid products that require larger bags or custom volumes. Its wide format range and durable structure make it perfect for businesses needing packaging flexibility and operational stability. ZL300P is designed for comprehensive vertical packaging lines and can be paired with a wide range of devices, such as auger fillers, multi-head weighers, liquid pumps, and discharge conveyors, ideal for varied production needs.

Machine Parameters

| Specifications | ZL-300P | ZL-180P | ZL-180PH(high speed) | ZL-200P | ZL-200PH(high speed) |

| Bagging size range | L80-400 mm | L50-190 mm | L50-190 mm | L 50-300 mm | L50-300 mm |

| W200-295 mm | W50-150 mm | W50-150 mm | W90-200 mm | W90-200 mm | |

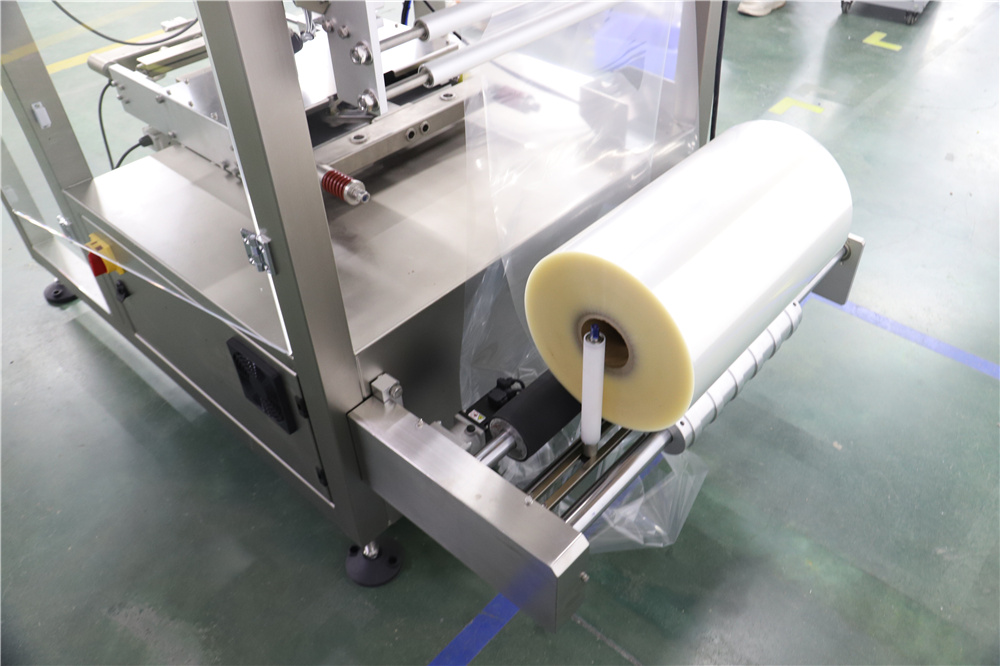

| Packing fim width | 420-620 mm | 100-320 mm | 100-320 mm | 200-420 mm | 200-420 mm |

| Packing speed | 15-60 bags/min | 20-100 bags/min | 20-100 bags/min | 20-90 bags/min | 20-120 bags/min |

| General power | 4.65 Kw | 3.9 Kw | 4.65 Kw | 3.9 Kw | 4.9 Kw |

| Power supply | 220V/1Ph/50Hz | 220V/1Ph/50Hz | 220V/1Ph/50Hz | 220V/1Ph/50Hz | 220V/1Ph/50Hz |

| Machine weight | 600 kg | 220kg | 250kg | 240 kg | 280 kg |

| Machine dimensions | 1620×1380x1680 mm | 1112x1170x1460 mm | 1200x1170x1460 mm | 1300×1170x1582 mm | 1427×1170x1562 mm |

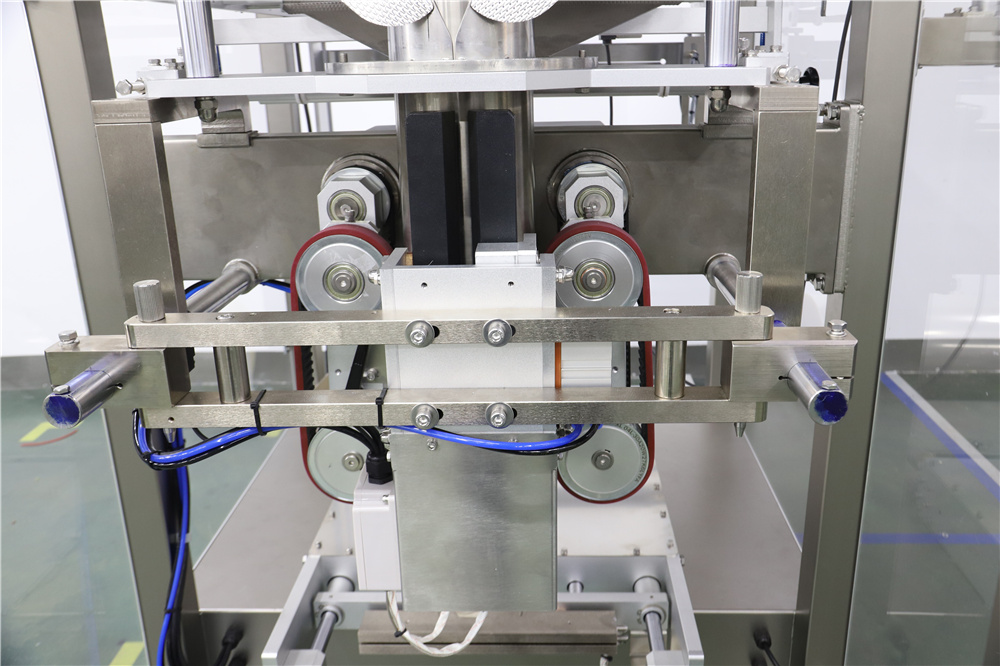

| End Sealing | Open-close motion | Open-close motion | Continuous motion | Open-close motion | Continuous motion |

| Packing material |

PP,CPP,PVC,PS,EVA,PET,PVDC+PVC,OPP/CPP,etd. |

||||

| View Machine | View Machine | View Machine | View Machine | ||

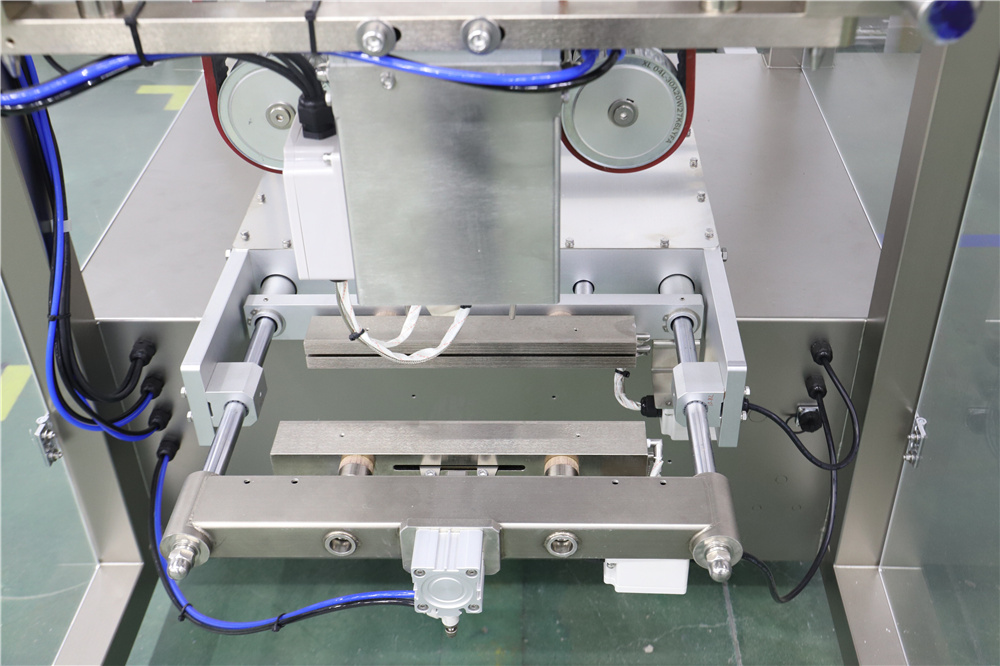

Key Features

- Built for medium- to high-volume production lines requiring stable long-hour performance.

- Supports multi-head weigher, auger filler, and liquid pump configurations.

- Handles large format pillow bags and gusseted bags.

- Intelligent temperature control ensures consistent sealing for food and non-food materials.

- Ideal for bulk packaging in industries like food, chemicals, and hardware.

Application

-

Biscuit & Cookie Packaging Solutions

-

Candy Packaging Solutions

-

Chocolate Packaging Solutions

-

Dried Fruits Packaging Solutions

-

Frozen Food Packaging Solutions

-

Nuts Packaging Solutions

-

Oil Packaging Solutions

-

Coffee Powder Packaging Solutions

-

Puffed Food Packaging Solutions

-

Detergent Powder Packaging Solutions

-

Seasoning Powder Packaging Solutions

-

Pet Food Packaging Solutions

-

Rice & Cereal Packaging Solutions

-

Sugar & Salt Packaging Solutions

-

Medical Supplies Sterile Packaging Solutions

-

Personal Care Liquid Packaging Solutions

-

Sauce Packaging Solutions

-

Beverage Packaging Solutions

-

Secondary Packaging (Random Bag Packaging Solutions)

Bag Type

Competitive Advantage

Built for larger format bags and heavier production loads, the ZL300P surpasses many standard vertical packaging machines in both bag size flexibility and material handling capacity. It supports advanced integration with multi-head weighers, auger fillers, and liquid pumps, making it an ideal solution for bulk packaging lines across diverse industries. Despite its capacity to handle large bags, the ZL300P sustains efficient output speeds of up to 60 packs per minute without compromising sealing integrity. Few models in its class can match the ZL300P’s combination of reliability, adaptability, and consistent high-speed performance across various material types.

Why Choose Soontrue?

When it comes to multi-material packaging systems, Soontrue leads the industry with solutions that offer speed, reliability, and versatility. The ZL300P is built to handle both high-output demands and bulk packaging, making it ideal for large factories in sectors like food, chemicals, and pharmaceuticals. Our global expertise, engineering precision, and fast installation times help you achieve operational excellence while keeping costs down. Soontrue also offers comprehensive training and ongoing support to ensure long-term value.

FAQ - ZL300P Vertical Packaging Machine

Q1: What types of materials can the ZL series vertical packaging machines handle?

A1: All ZL series models are designed to handle powder, granules, and liquid or paste materials. This makes them suitable for packaging items such as flour, coffee powder, detergent, milk powder, sauces, shampoo, edible oil, and more.

Q2: What is the maximum packaging speed for this model?

A2: The ZL300P runs at 15–60 bags per minute, designed for large-bag, low-speed packaging needs.

Q3: Can this machine be integrated with other systems like cartoners or case packers?

A3: Yes, all ZL models can be seamlessly integrated with multi-head weighers, augers, liquid pumps, as well as downstream equipment such as cartoning machines, case erectors, and palletizing systems. This ensures complete automation and improved productivity.

Q4: Which industries are best suited for ZL vertical packaging machines?

A4: These machines are widely used in food, chemical, pharmaceutical, and daily chemical industries, offering flexible solutions for both solid and liquid products.

Q5: Is it easy to operate and maintain the ZL machines?

A5: Absolutely. The ZL series features a user-friendly HMI touchscreen, tool-free changeover, film auto centering, and easy-to-clean stainless steel structure. Daily maintenance is minimal and requires no advanced technical background.

Q6: What kind of after-sales service do you provide?

A6: Soontrue provides comprehensive after-sales service, including on-site installation, training, remote diagnostics, and 12-month warranty for all core components. Our global service team ensures fast response wherever you are.

Q7: Can this machine be customized based on product or plant layout?

A7: Yes, ZL300P is often integrated with bulk feeding hoppers or double augers for heavy-duty or volumetric filling tasks.