SZ750W Box Motion Packaging Machine

SZ750W Box Motion Packaging Machine Typical Applications

- Bakery: bread, cakes, buns, and tray-packed pastries.

- Frozen Food: dumplings, seafood, meat products with medium-to-large packs.

- Confectionery: chocolate multipacks, candy bags.

- Household & Industrial: daily-use goods, hardware kits, medical supplies.

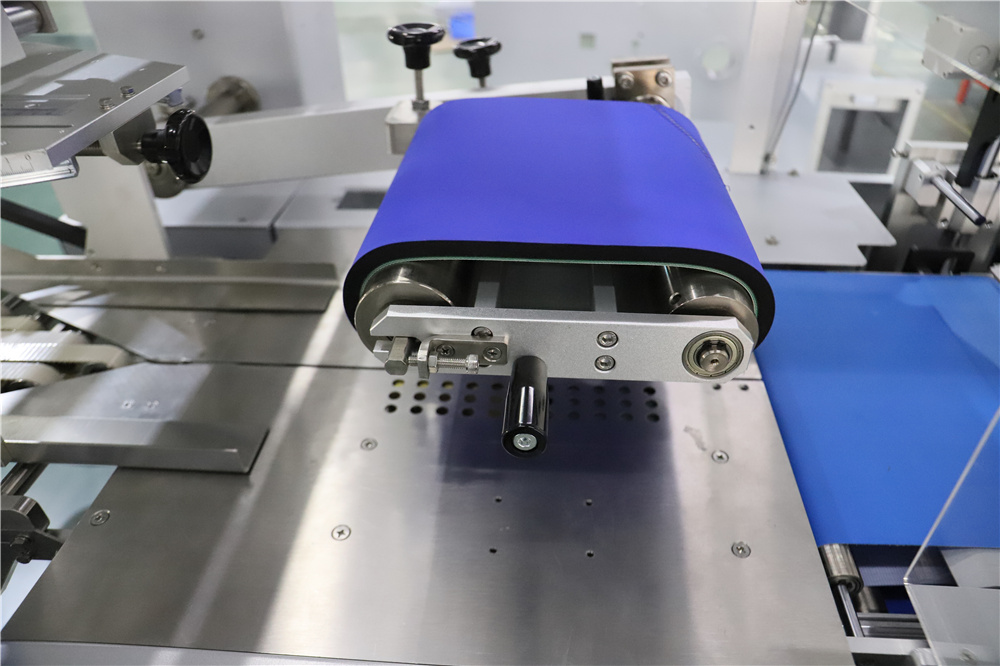

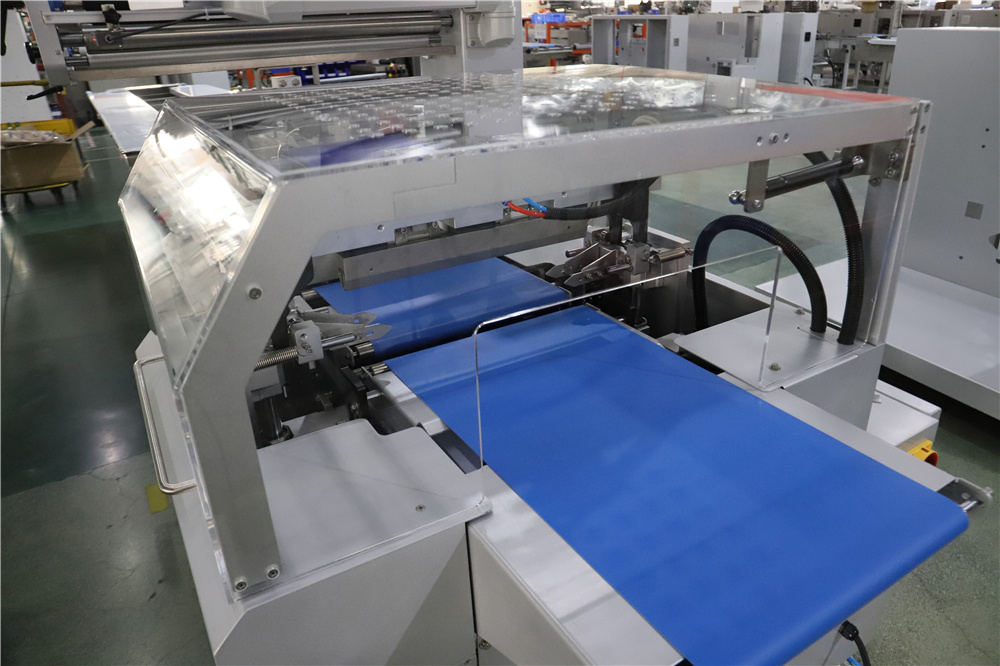

The SZ750W Box Motion Flow Wrapping Machine is a cost-effective horizontal packaging system designed for film widths up to 750 mm and speeds of 25–60 packs per minute. Unlike high-end stainless steel models such as the SZ801W, the SZ750W features a carbon steel frame, making it an affordable option while still delivering reliable performance.

Its box motion sealing apply extended dwell time and pressure, ensuring airtight, durable seals even on laminated or barrier films. This makes the SZ750W particularly suitable for frozen food, bakery products, and tray-based packaging, where seal quality is critical.

Driven by servo motors, the SZ750W ensures accurate film pulling, stable feeding, and consistent sealing results. With its balance of performance and affordability, it is ideal for manufacturers who need strong seal integrity and wide-film adaptability without investing in premium models.

Machine Parameters

| Specifications | SZ750W | SZ750W | SZ602W | SZ280W | SW60E |

| Centerdistanoe | 120 mm | 160 mm | 120 mm | 120 mm | |

| Bagging size range | L120-600 mm | L120-600 mm | L120-600 mm | L120-600 mm | L90-450 mm |

| W150-330 mm | W70-200 mm | W70-200mm | W70-200mm | W10-180 mm | |

| Product size range | H5-80 mm | H 60-110 mm | H 5-80 mm | H 5-80 mm | H5-60 mm |

| Packing speed | 25-60 bags/min | 20-60 bags/min | 20-80 bags/min | 20-80 bags/min | 30-120 bags/min |

| Packing fim width | 300-750 mm | Max.600 mm | 200-600 mm | 90-420 mm | |

| Power supply | 220V/1Ph/50Hz | 220V/1Ph/50Hz | 220V/1Ph/50Hz | 220V/1Ph/50Hz | |

| General power | 7.6 Kw | 8.6 KW | 6.5Kw | 8.0Kw | |

| Machine weight | 700 kg | 800 kg | 775 kg | 700 kg | |

| Machine dimensions | 4300x1250x 1560 mm | 4500x1070x 1590 mm | 4300x1100x1560 mm | 4140x870x1630 mm | |

| Packing material |

OPP,PVC,OPP/CPP,PT/PE,KOP/CPP,etc. |

||||

| View Machine | View Machine | View Machine | |||

📌 Reference: Internal test data by Soontrue R&D Lab (2024)

Key Features

- Box Motion Sealing Technology: The SZ750W uses advanced Box motion sealing, ensuring smooth and secure sealing even at high speeds. This technology provides greater control over the sealing process, allowing for precise and reliable packaging.

- Horizontal Form Fill Seal (HFFS) Machine: The SZ750W operates as a horizontal form fill seal machine, making it highly suitable for industries requiring efficient, high-speed packaging of various products, including food, pharmaceuticals, and consumer goods.

- Flexible Packaging Solutions: With its flow wrapper packaging machine capabilities, the SZ750W is capable of handling a variety of packaging materials, offering flexibility in different applications and industries.

Application

-

Chocolate Packaging Solutions

-

Candy Packaging Solutions

-

Bread & Bakery Packaging Solution

-

Biscuit & Cookie Packaging Solutions

-

Organized Bag Secondary Packaging Solutions

-

Noodle Packing Solutions

-

Medical Supplies Sterile Packaging Solutions

-

Household & Hotel Goods Packaging Solutions

-

Hardware Packaging Solutions

-

Vegetable & Fruit Packaging Solutions

-

Disposable Goods Packaging Solutions

-

Meat Poultry & Seafood Packaging Solutions

-

Frozen Food Packaging Solutions

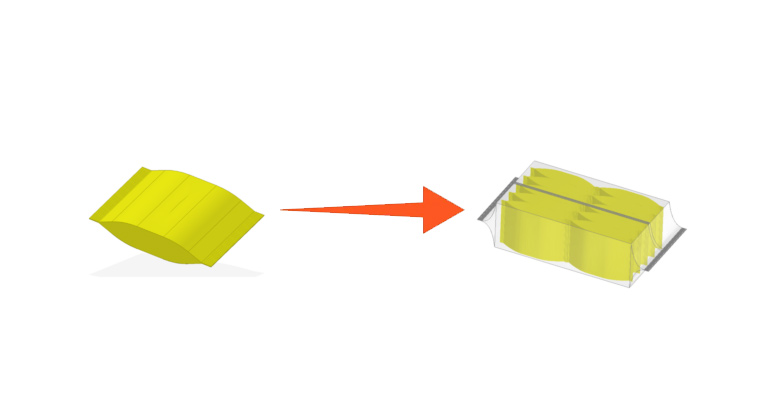

Bag Type

Competitive Advantage

For many buyers, the challenge is finding a machine that balances cost, seal quality, and film width. Competitor models often force a trade-off: low-cost machines with weak seals or premium machines with higher prices. The SZ750W directly solves this gap.

- Cost Advantage vs. High Investment: While stainless steel machines can be expensive, the SZ750W’s carbon steel frame lowers purchase cost while maintaining reliable sealing performance—perfect for businesses with budget constraints.

- Seal Integrity vs. Leakage Issues: Cheaper competitors often fail with laminated or thicker films, causing leaks and product waste. The SZ750W’s box motion sealing provide airtight, consistent seals, protecting product freshness.

- Wide Film Handling vs. Limitations: Many economic machines are restricted to narrow films (<600 mm), limiting product size. The SZ750W supports film widths up to 750 mm, making it versatile for bakery trays, frozen food packs, and larger retail bags.

- Balanced Speed vs. Downtime: With a stable speed of 25–60 packs/min, the SZ750W offers enough capacity for medium-scale production while maintaining low maintenance costs compared to high-speed models.

👉 In short, the SZ750W gives buyers strong sealing and wider film capability at an affordable price point—something few competitors can match.

Why Choose Soontrue as Your Packaging Machine Manufacturer?

Many buyers hesitate between low-cost suppliers with poor reliability and high-end machines that exceed their budget. Soontrue bridges this gap. With 30+ years of expertise and 600+ patents, we deliver packaging solutions that combine cost-efficiency with proven technology. The SZ750W reflects this balance—an economic yet robust option trusted by manufacturers worldwide. Unlike suppliers who disappear after delivery, Soontrue provides installation, training, spare parts, and 24/7 service support across 120+ countries. All machines meet CE, FDA, and ISO standards, ensuring compliance for global markets. By choosing Soontrue, buyers get more than a machine—they secure a partner focused on ROI, reliability, and long-term growth.

FAQ About SZ750W Box Motion Packaging Machine

Q1: Is the SZ750W suitable for laminated or barrier films?

A1: Yes, the box motion sealing provide extended dwell time, making it ideal for laminated and aluminum-coated films.

Q2: What is the difference between SZ750W and SZ801W?

A2: The SZ750W is an economic model with a carbon steel frame, 25–60 ppm speed, and max 750 mm film width, while the SZ801W is a higher-end stainless steel model for 900 mm film width and larger products.

Q3: Who is the SZ750W best suited for?

A3: Medium-scale manufacturers who need wide film adaptability and strong seals at a lower investment cost.

Q4: Can the SZ750W be integrated into a full packaging line?

A4: Yes, it can be connected with automatic feeders, printers, metal detectors, and downstream case packers, providing flexibility for future expansion.

Q5: What after-sales support does Soontrue provide for SZ750W buyers?

A5: Soontrue offers on-site installation, operator training, spare parts supply, and 24/7 remote support. With service coverage in 120+ countries, downtime is minimized.