SZ601W Box Motion Packaging Machine

SZ601W Box Motion Packaging Machine Typical Applications

- Frozen Food: dumplings, seafood, meat cuts, frozen vegetables.

- Bakery: mooncakes, tray-packed pastries, bread rolls.

- Daily Products: tissues, wipes, sanitary products.

- Industrial & Medical: hardware kits, medical devices, spare parts.

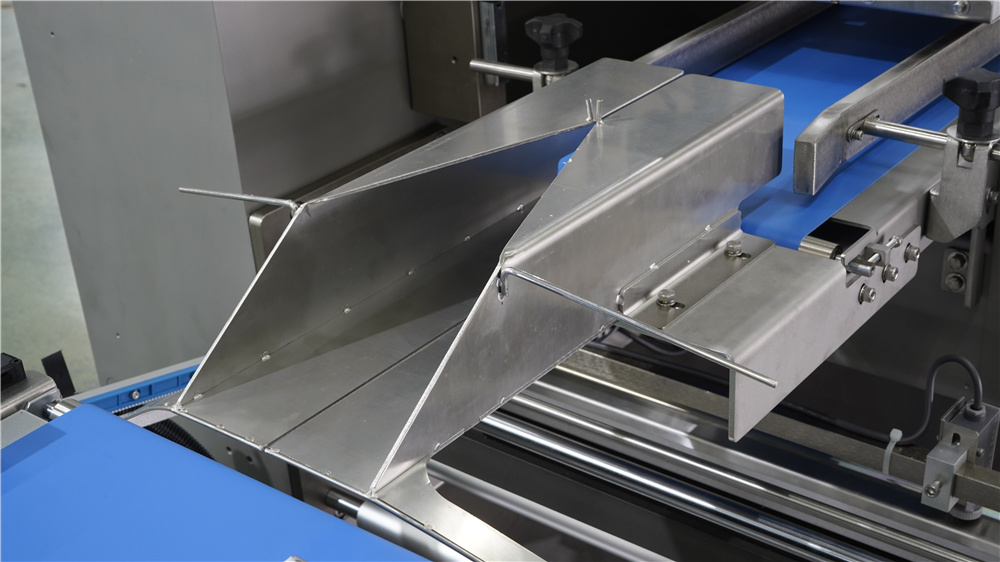

The SZ601W Bottom Film Box Motion Flow Wrapping Machine is a horizontal packaging system built for 20–80 packs/min and film widths up to 600 mm. Its unique bottom film feeding system ensures that products remain firmly positioned on the infeed conveyor, making it ideal for soft, heavy, or irregularly shaped goods that are difficult to handle with top film machines.

Constructed with a stainless steel frame, the SZ601W guarantees food-grade hygiene and durability. The box motion sealing deliver extended dwell time and high pressure, ensuring airtight, reliable seals for laminated and barrier films—perfect for frozen or moisture-sensitive products.

Combined with servo-driven controls, the SZ601W reduces misalignment, minimizes film waste, and ensures consistent pack quality. It is the preferred solution for manufacturers requiring bottom film stability, strong sealing, and stainless steel hygiene at medium speeds.

Machine Parameters

| Specifications | SZ601W | SZ601W |

SZ750XW |

SZ750XW |

| Centerdistanoe | 120 mm | 160 mm | 120 mm | 160 mm |

| Bagging size range | L120-600 mm | L120-600 mm | L120-600 mm | L120-600 mm |

| W70-200 mm | W70-200 mm | W150-330 mm | W150-330 mm | |

| Product size range | H5-80 mm | H 60-120 mm | H5-80 mm | H60-120 mm |

| Packing speed | 20-80 bags/min | 25-60 bags/min | ||

| Packing fim width | Max.600 mm | 300-750 mm | ||

| Power supply | 220V/1Ph/50Hz | 220V/1Ph/50Hz | ||

| General power | 9 Kw | 7.6 kW | ||

| Machine weight | 800 kg | 700 kg | ||

| Machine dimensions | 5350x1230x1470 mm | 4325x1325x1410 mm | ||

| Packing material | OPP,PVC,OPP/CPP,PT/PE,KOP/CPP etc. | |||

| View Machine | ||||

📌 Reference: Internal test data by Soontrue R&D Lab (2024)

Key Features

- Bottom Film Feeding with Box Motion Sealing: Unlike the SZ602W that uses top film, the SZ601W is designed with bottom film feeding and Box motion technology, allowing for stable and precise packaging of products that may be delicate or require special handling.

- Flow Pack Packaging: The SZ601W is optimized for flow pack packaging, ensuring smooth and efficient wrapping processes, especially for products with specific placement requirements.

- Stainless Steel Construction: The machine’s full stainless steel body ensures longevity and ease of cleaning, adhering to high hygiene standards required by industries such as food processing, pharmaceuticals, and more.

- Horizontal Form Fill Seal Machine (HFFS): With its advanced horizontal form fill seal (HFFS) capabilities, the SZ601W delivers reliable and high-quality packaging for a wide range of products.

Application

-

Organized Bag Secondary Packaging Solutions

-

Disposable Goods Packaging Solutions

-

Candy Packaging Solutions

-

Bread & Bakery Packaging Solution

-

Biscuit & Cookie Packaging Solutions

-

Medical Supplies Sterile Packaging Solutions

-

Household & Hotel Goods Packaging Solutions

-

Hardware Packaging Solutions

-

Meat Poultry & Seafood Packaging Solutions

-

Frozen Food Packaging Solutions

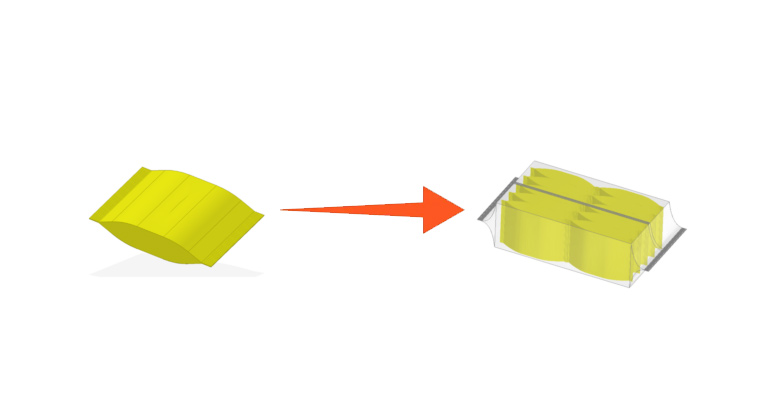

Bag Type

Competitive Advantage

Compared with standard top film machines, the SZ601W bottom film model directly:

- Product Stability vs. Misalignment: Top film machines often struggle with heavy or irregular items that shift during wrapping. The SZ601W's bottom film system keeps products stable, reducing rejects and improving packaging consistency.

- Seal Reliability vs. Leakage: Rotary sealers may fail on laminated or frozen food films. The SZ601W's box motion sealing ensures airtight seals to protect freshness and prevent leakage.

- Hygiene vs. Corrosion Risks: Low-cost carbon steel wrappers corrode over time. The SZ601W's stainless steel body ensures hygiene and compliance with food safety standards.

- Balanced ROI vs. Overspending:High-speed, large-film machines may exceed customer needs. The SZ601W provides 20–80 ppm capacity with 600 mm film, delivering reliable ROI at a moderate investment.

👉 The SZ601W is the go-to solution for frozen food and bakery producers needing bottom film stability, reliable sealing, and stainless steel hygiene.

Why Choose Soontrue as Your Packaging Machine Manufacturer?

Many manufacturers face issues with unstable feeding, poor sealing, and low service support. Soontrue eliminates these risks. With 30+ years of expertise, 600+ patents, and installations in 120+ countries, the SZ601W Bottom Film Box Motion Machine delivers proven performance. Its stainless steel design, bottom film feeding, and box motion sealing ensure hygiene, stability, and strong seals. Backed by CE/FDA compliance and a global service network offering training, spare parts, and 24/7 support, Soontrue is not just a supplier but a long-term packaging partner.

FAQ About SZ601W Box Motion Packaging Machine

Q1: What is the speed range of the SZ601W?

A1: 20–80 packs/min, suitable for medium-scale production.

Q2: What is the difference between SZ601W and SZ602W?

A2: The SZ601W uses bottom film feeding, ideal for heavy/soft products. The SZ602W uses top film feeding, more suitable for snacks and bakery.

Q3: What types of films can SZ601W handle?

A3: It supports laminated and aluminum-coated barrier films, ensuring airtight seals.

Q4: Is it suitable for frozen and irregular products?

A4: Yes, the bottom film system keeps dumplings, meat, and other irregular products stable during wrapping.

Q5: What after-sales service is provided?

A5: Soontrue offers installation, training, spare parts, and 24/7 remote support in over 120 countries.