SW60E Pillow Pack Wrapping Machine

SW60E Pillow Pack Wrapping Machine Typical Applications

- Daily Necessities

- Bakery Industry

- Pharmaceutical Products

- Hardware Items

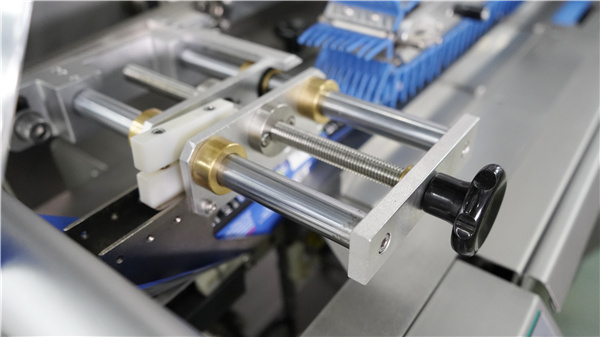

The SW60E Pillow Pack Wrapping Machine is a high-speed horizontal flow wrapper featuring a box motion end sealing system. Unlike rotary sealing systems, the box motion ensures tighter, stronger, and more stable seals, making it ideal for packaging products with high aesthetic or hygiene requirements.

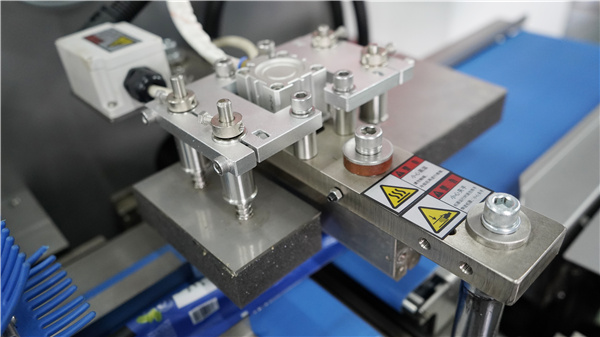

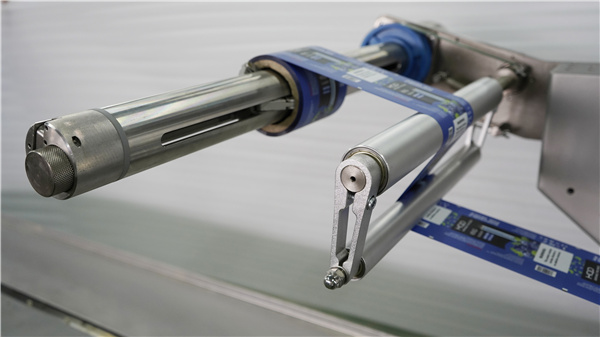

Powered by a servo control system, the SW60E delivers precise control over film feeding and cutting, enabling seamless operation across various product sizes. Its advanced sealing technology supports multi-layer laminated films and complex film materials, commonly used in bakery, frozen food, personal care, and medical packaging.

Whether integrated into a full packaging line or used independently, SW60E offers outstanding performance for businesses aiming to boost output while maintaining premium packaging quality.

Machine Parameters

| Specifications | SW60E | SW80E | SZ280W | SZ602W | SZ750W |

| Bagging size range | L90-450 mm | L90-450 mm | L120-600 mm | L120-600 mm | L120-600 mm |

| Product size rgnge | W10-180 mm | W35-200 mm | W70-200 mm | W70-200 mm | W150-330 mm |

| H 5-60 mm | H 5-80 mm | H 5-80 mm | H 5-80 mm | H 5-80 mm | |

| Packing speed | 30-120 bags/min | 30-100 bags/min | 25-60 bags/min | 20-80 bags/min | 25-60 bags/min |

| Packing fim width | 90-420 mm | 90-500 mm | 200-600 mm | Max.600 mm | 300-750 mm |

| Power supply | 220V/1Ph/50Hz | 220V/1Ph/50Hz | 220V/1Ph/50Hz | 220V/1Ph/50Hz | 220V/1Ph/50Hz |

| General power | 7.5 KW | 8.0 KW | 6.5 KW | 8.6 KW | 7.6 KW |

| Machine weight | 700 kg | 700 kg | 775 kg | 800 kg | 700 kg |

| Machine dimensions | 4140x870x1630 mm | 4360x1020x1540 mm | 4300x1100x 1560 mm | 4500x1070x1590 mm | 4300x1250x1560 mm |

| Packing material | PP,PVC,PS,EVA,PET,PVDC+PVC,OPP+CPP etc. | ||||

| View Machine | View Machine | View Machine | View Machine | ||

📌 Reference: Internal test data by Soontrue R&D Lab (2024)

Key Features

- High-Speed Box Motion Sealing: Equipped with a high-performance box motion end sealing system, SW60E delivers tight, stable seals even at high throughput, ideal for products requiring strong shelf appeal and extended freshness.

- Advanced Servo Control System: Full servo control over film transport, product feeding, and sealing ensures high precision, reduced film waste, and consistent output, especially useful for high-volume operations.

- Multi-Film Compatibility: Supports various film types including laminated films, PE, and complex barrier films, making it suitable for a wide range of industries such as bakery, frozen food, medical devices, and cosmetics.

- Smart Touchscreen Interface: Easy-to-use HMI with recipe memory, production data tracking, and error diagnostics enables quick changeovers and operator-friendly control.

- Flexible Product Handling: Adapts to different product lengths and shapes without requiring extensive mechanical adjustments, supporting both single and grouped product packaging.

- Hygienic Design & Easy Maintenance: Constructed with stainless steel and modular parts, allowing for tool-free access and cleaning, especially beneficial for food and pharmaceutical packaging.

Application

-

Bread & Bakery Packaging Solution

-

Disposable Goods Packaging Solutions

-

Organized Bag Secondary Packaging Solutions

-

Chocolate Packaging Solutions

-

Frozen Food Packaging Solutions

-

Meat Poultry & Seafood Packaging Solutions

-

Noodle Packing Solutions

-

Vegetable & Fruit Packaging Solutions

-

Hardware Packaging Solutions

-

Household & Hotel Goods Packaging Solutions

-

Medical Supplies Sterile Packaging Solutions

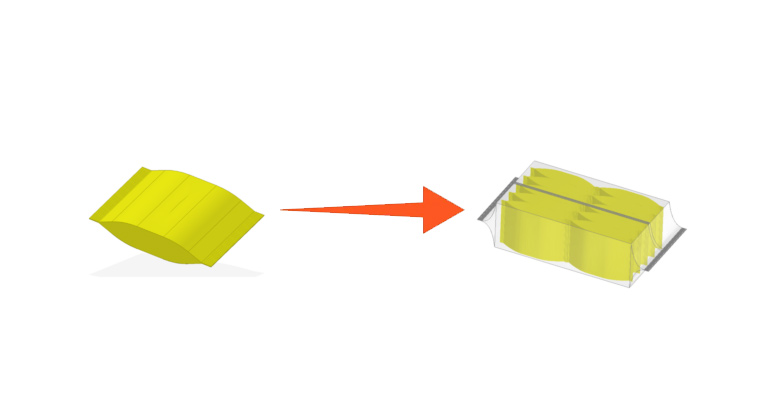

Bag Type

Competitive Advantage

- Higher Speed, Smarter Motion

While many pillow packing machines on the market use rotary sealing for general speed, the SW60E adopts box motion end sealing — a reciprocating sealing mechanism that allows for tighter, stronger seals at higher speeds, especially for thicker or laminated films. Compared to standard rotary models, SW60E offers 20–30% better sealing quality for demanding applications.

- Full Servo Integration vs. Partial Servo Designs

Many competing machines still rely on mechanical cams or partial servo setups. The SW60E features a full servo system, enabling real-time motion coordination, smoother transitions, and dramatically reduced maintenance costs. This translates to better machine uptime and fewer mechanical adjustments.

- Better ROI with Long-Term Value

Though more advanced, SW60E reduces film waste, shortens downtime, and lowers long-term maintenance, offering a faster payback period compared to similar high-speed machines from European or Japanese brands—without sacrificing quality.

Why Choose Soontrue?

Choosing Soontrue means investing in smart, reliable, and scalable packaging automation backed by over 30 years of industry experience. As a leading manufacturer of flow wrappers and end-of-line systems, we’ve designed the SW60E not just to meet today's speed and hygiene demands, but to future-proof your production line with full servo control, box-motion sealing, and intelligent integration.

When you choose Soontrue, you're not just buying a machine — you're partnering with a team dedicated to long-term packaging performance, efficiency, and competitive edge.

FAQ - SW60E Pillow Pack Wrapping Machine

Q1: What types of products can the SW60E wrap?

A1: The SW60E is ideal for high-speed pillow-style packaging of snacks, baked goods, frozen foods, medical supplies, and tray-loaded items. Its box motion sealing ensures excellent performance for both regular and irregular shapes.

Q2: What is box motion sealing, and why is it important?

A2: Box motion sealing allows the end seal jaws to move horizontally with the film while sealing, ensuring longer sealing time, stronger seals, and better appearance—perfect for high-barrier and thicker films.

Q3: Can the SW60E work with printed films?

A3: Yes, the machine supports both printed and unprinted films, thanks to its photoelectric tracking system that ensures accurate film alignment and registration.

Q4: What is the typical speed range of the SW60E?

A4:Depending on product size and film type, the SW60E can run up to 30–120 packs per minute, offering high efficiency for demanding production environments.

Q5: Is the machine easy to clean and maintain?

A5: Absolutely. The SW60E is designed with a stainless steel frame, modular components, and tool-free changeover, making it easy to clean, maintain, and adjust.

Q6: Can Soontrue customize the SW60E based on my factory layout or product type?

A6: Yes. Soontrue offers custom configurations for different industries and layouts, including multi-lane feeders, auto-loading systems, and integration with downstream equipment.