SW80X Horizontal Flow Wrapping Machine

SW80X Horizontal Flow Wrapping Machine Typical Applications

- Bakery & Confectionery: sliced bread, biscuits, cookies, chocolate bars, cakes, and pastries

- Snacks & Convenience Foods: instant noodles, energy bars, frozen dumplings, and ready-to-eat items

- Household & Daily Products: tissues, wet wipes, disposable tableware, and sanitary goods

- Industrial & Hardware Items: small tools, spare parts, electronic accessories, and hardware kits

- Medical & Healthcare Products: syringes, gauze packs, bandages, and other sterilized consumables

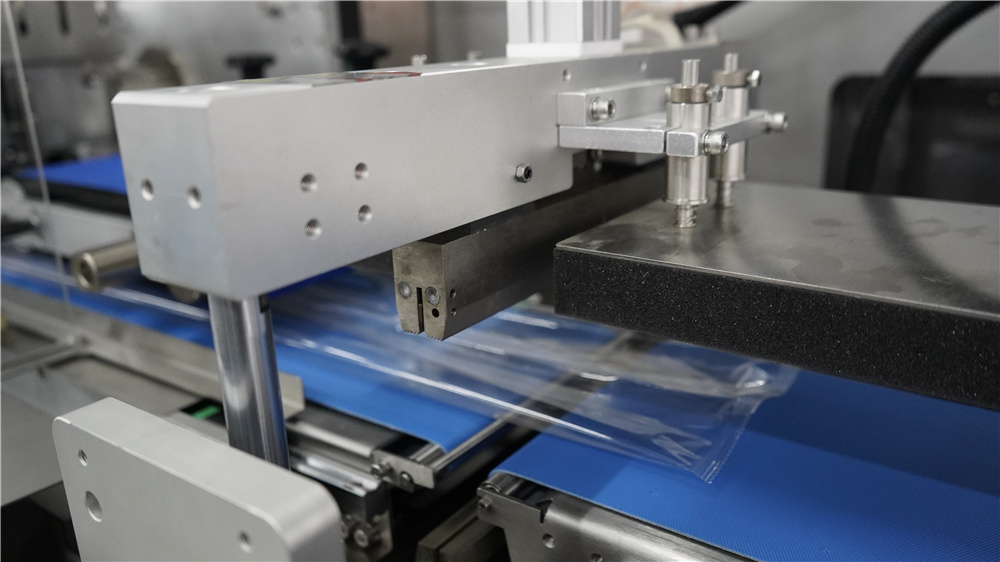

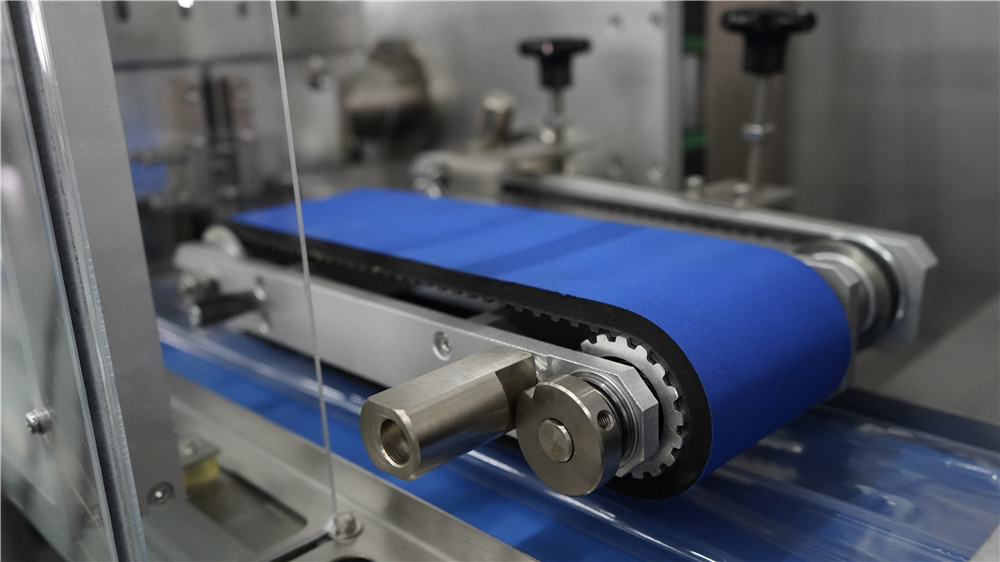

The SW80X is a high-performance horizontal flow wrapping machine designed to provide stable, hygienic, and efficient packaging for medium-to-large products that require strong sealing quality. Unlike top-film flow wrappers, the SW80X uses a bottom-film feeding system, which allows the product to remain stable on the conveyor during film wrapping. This is especially important for heavier, softer, or irregularly shaped items such as bread, bakery goods, frozen foods, or hardware kits, where conventional top-film feeding could cause misalignment or damage.

Another distinguishing feature is its box-motion end sealing system, which provides a longer dwell time compared to rotary sealing. This ensures stronger, more consistent seals, even when running at higher speeds or using thicker/layered packaging films required for products with extended shelf life.

The SW80X is fully servo-driven, meaning each axis (film pulling, sealing, product feeding) is controlled with precision, reducing film waste and ensuring consistent packaging accuracy. Built with a stainless-steel structure, it meets food industry hygiene requirements and is easy to clean and maintain. The machine is also designed for integration with printers, metal detectors, checkweighers, and other end-of-line equipment, making it a versatile and reliable choice for manufacturers aiming to automate high-volume packaging lines.

Machine Parameters

| Specifications | SW60X | SW80X | SZ280XW | SZ750XW | SZ801w |

| Bagging size range | L90-450 mm | L90-450 mm | L120-600 mm | L120-600 mm | L150-600 mm |

| Product size rgnge | W10-180 mm | W35-200 mm | W70-200 mm | W150-330 mm | W70-350 mm |

| H 5-60 mm | H 5-80 mm | H 5-80 mm | H 5-80 mm | H 60-130 mm | |

| Packing speed | 30-120 bags/min | 30-100 bags/min | 25-60 bags/min | 25-60 bags/min | 20-50 bags/min |

| Packing fim width | 90-420 mm | 90-500 mm | 200-600 mm | 300-750 mm | MAX. 900 mm |

| Power supply | 220V/1Ph/50Hz | 220V/1Ph/50Hz | 220V/1Ph/50Hz | 220V/1Ph/50Hz | 220V/1Ph/50Hz |

| General power | 8.0 KW | 8.0 KW | 6.6 KW | 7.6 KW | 8.6 KW |

| Machine weight | 730 kg | 750 kg | 775 kg | 800 kg | 850 kg |

| Machine dimensions | 4820x1065x1450 mm | 5100x1100x1500 mm | 4330x1130x 1410 mm | 4325x1325x1410 mm | 2800x1320x1610 mm () |

| Packing material | PP,PVC,PS,EVA,PET,PVDC+PVC,OPP+CPP etc. | ||||

| View Machine | View Machine | View Machine | View Machine | ||

📌 Reference: Internal test data by Soontrue R&D Lab (2024)

Key Features

- Box-Motion End Sealing — Extended seal dwell for tighter, more reliable seals at industrial speeds.

- Full-Servo Control — Precise film pull, jaw timing, and feeding synchronization improve yield and reduce waste.

- Stainless-Steel Body — Durable, cleanable construction for food and non-food environments.

- Wide Size Window — Wraps 35–200 mm width / 5–80 mm height products; bag 90–450 mm.

- Air-Assisted Actuation — Uses external compressed air for consistent mechanical response.

- Options Ready — washdown, hole punch, gas flush, static elimination, tear-notch, remote diagnostics; integration with printers/MD/checkweighers.

Application

-

Bread & Bakery Packaging Solution

-

Organized Bag Secondary Packaging Solutions

-

Chocolate Packaging Solutions

-

Frozen Food Packaging Solutions

-

Meat Poultry & Seafood Packaging Solutions

-

Noodle Packing Solutions

-

Vegetable & Fruit Packaging Solutions

-

Hardware Packaging Solutions

-

Household & Hotel Goods Packaging Solutions

-

Medical Supplies Sterile Packaging Solutions

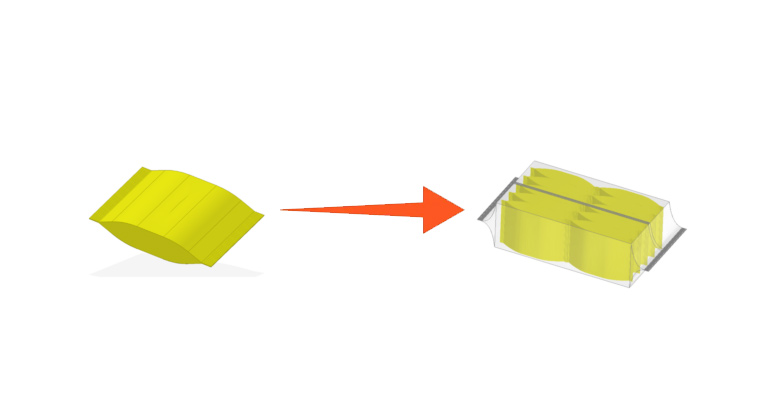

Bag Type

Competitive Advantage

Many conventional flow wrapping machines use top-film feeding and rotary sealing, which can create challenges when handling heavier, soft, or irregularly shaped products. The SW80X is designed to overcome these limitations, providing clear advantages for manufacturers who demand higher stability and sealing reliability:

- Bottom-Film Feeding vs. Top-Film Feeding:Unlike top-film machines where film tension can disturb product orientation, the SW80X’s bottom-film system keeps products stable, making it ideal for bread, bakery, frozen foods, and hardware kits.

- Box-Motion Sealing vs. Rotary Sealing:Rotary sealing offer shorter sealing time, which can lead to weak or inconsistent seals on thick films. The SW80X’s box-motion end seal provides longer dwell time, ensuring strong, airtight, and visually consistent seals even on challenging packaging materials.

- Servo-Driven Precision vs. Mechanical Systems:Where traditional mechanical wrappers may suffer from film misalignment and higher waste, the SW80X’s multi-servo control ensures accurate film pulling, synchronized feeding, and reduced material waste.

- Versatility and Integration:While competitor machines may need separate setups for different packaging features, the SW80X supports multiple bag types and options (gusseted, hole-punch, gas flush, tear notch) and integrates seamlessly with printers, detectors, and palletizers.

For buyers, these differences translate into fewer rewraps, lower downtime, stronger product presentation, and faster ROI compared with conventional flow wrapping equipment.

Why Choose Soontrue

Choosing Soontrue means partnering with a company that has over 30 years of expertise in flow wrapping and packaging automation. The SW80X is not just a machine—it reflects Soontrue’s engineering philosophy of reliability, adaptability, and customer-focused innovation.

Unlike generic flow wrappers on the market, the SW80X is optimized for challenging packaging tasks, such as heavier products, larger product dimensions, or applications requiring strong seals. Its bottom-film feeding and box-motion sealing give buyers a unique advantage in reducing rewraps, minimizing downtime, and maintaining product presentation quality.

Soontrue also provides:

- Global service support: Installation, training, and spare parts supply across multiple regions.

- Integration expertise: Full packaging line solutions including feeders, printers, checkweighers, and palletizing systems.

- Customization options: From bag types (gusset, quad-seal, euro-hole) to advanced modules (gas flush, tear notch, remote diagnostics).

- Long-term ROI: Machines designed for 24/7 operation, with servo technology that reduces waste and lowers total cost of ownership.

By choosing Soontrue, manufacturers secure a partner who not only supplies machines, but also provides continuous support, scalable solutions, and the confidence that their packaging line can adapt to evolving market demands.

FAQ - SW80X Horizontal Flow Wrapping Machine

Q1: What products benefit most from bottom-film feeding?

Items that are heavier, soft, or irregular (e.g., hardware kits, frozen portions, bulky bakery) where top-film drag can disturb orientation.

Q2: How fast can SW80X speed?

Spec speed is 30–100 bags/min, depending on product size, film, and seal quality requirements.

Q3: What's the size range?

Bag 90–450 mm; product W 35–200 mm, H 5–80 mm; film 90–500 mm.

Q4: Is it food-safe?

The stainless-steel body and available washdown construction support hygienic operation (confirm your target standards).

Q5: Can it support retail features like hang-holes or gas flush?

Yes—hole punch (euro/round), gas flush, tear-notch, static elimination, and more are available.

Q6: How does box-motion differ from rotary sealing?

Box-motion provides a linear, longer dwell sealing stroke, improving seal strength on thicker films or tall products; rotary is simpler but offers shorter dwell.