Packaging Machinery Outlook 2026

Packaging Knowledge Hub

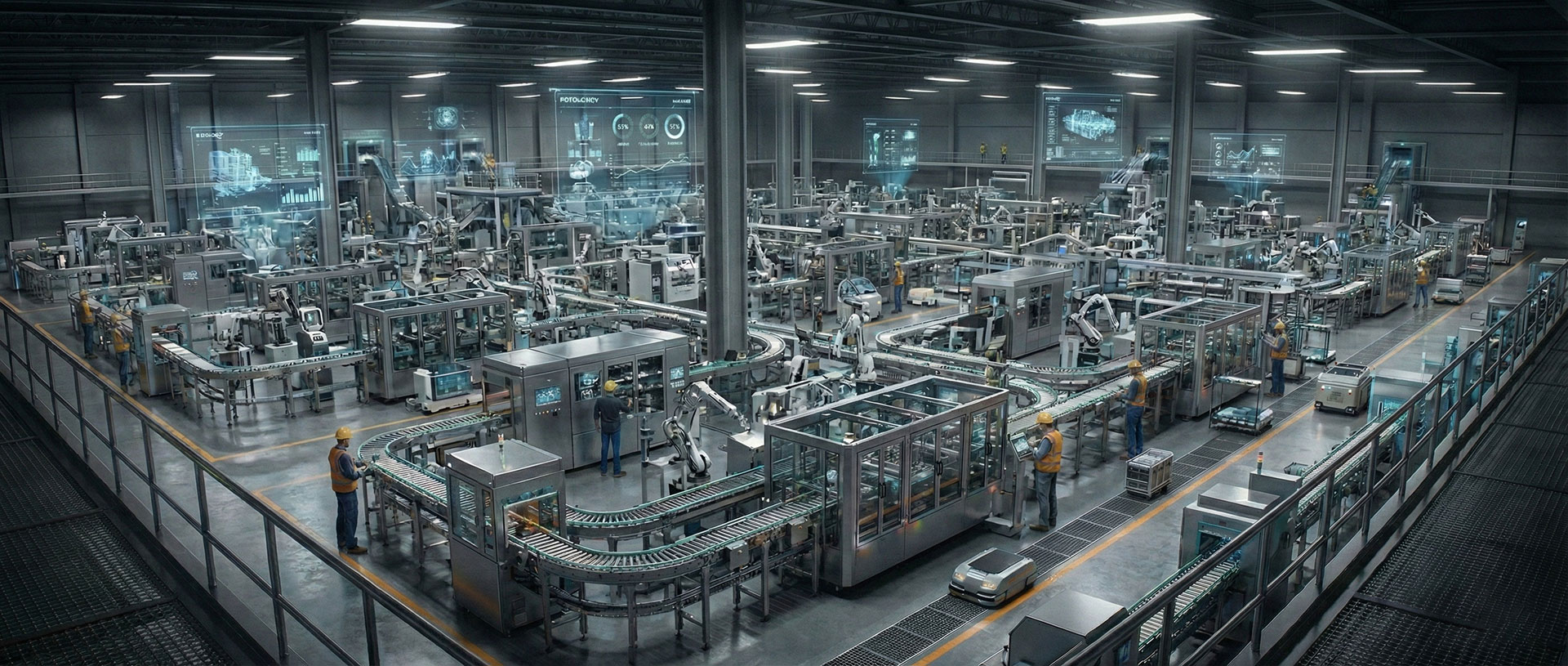

Explore the $71.1B packaging machinery market forecast for 2026. Learn how labor shortages and green materials (Mono-PE) are driving demand for VFFS, ultrasonic sealing, and IIoT automation.

Detail