From Standalone Machines to Integrated Lines in Food Packaging Automation 2026 Guide

Packaging Knowledge Hub

If you're seeking packaging automation solutions, please contact us, and we'll be delighted to offer you the most tailored solution.

In the food sector of industrial manufacturing, the efficiency and consistency of the packaging processing line directly determine its market competence. Earlier on, in lots of factories for food processing, automatic packaging machines were used individually to perform the end-of-line tasks. But now, as we make our way through 2026, things are different.

Facing a "Perfect Storm" of increasing labor costs, stricter sanitation regulations (like FSMA and HACCP), and the demand for real-time data visibility, the industry is shifting. The evolution from individual machines to fully integrated system solutions is no longer just an option—it is the ultimate road to profitability.Data shows that integrated lines can reduce labor costs by up to 30% while boosting Overall Equipment Effectiveness (OEE) by over 20%.

This guide explores why integrating your industrial packaging machinery into a cohesive line is the smartest investment for modern food factories.

The Limitations of Standalone Automatic Packaging Machines in Food Production

Automatic packaging machines can quickly complete processes such as measurement, bagging, and sealing, making them suitable for production environments with stable output and uniform product specifications. However, when faced with multi-variety, small-batch orders or complex production processes, standalone machines often encounter the following issues:

Poor process connectivity: Manual handling or material transfer is required, increasing time and the risk of errors.

Information silos: Standalone machines lack data communication with upstream and downstream processes,This creates "blind spots" where managers cannot track real-time yield or pinpoint exactly where bottlenecks occur.

Insufficient scalability: Adding new functions requires additional equipment investment, and modifications can be challenging.

As a result, more and more companies are considering integrating standalone machines into automated packaging line systems to achieve higher levels of flexibility and intelligence.

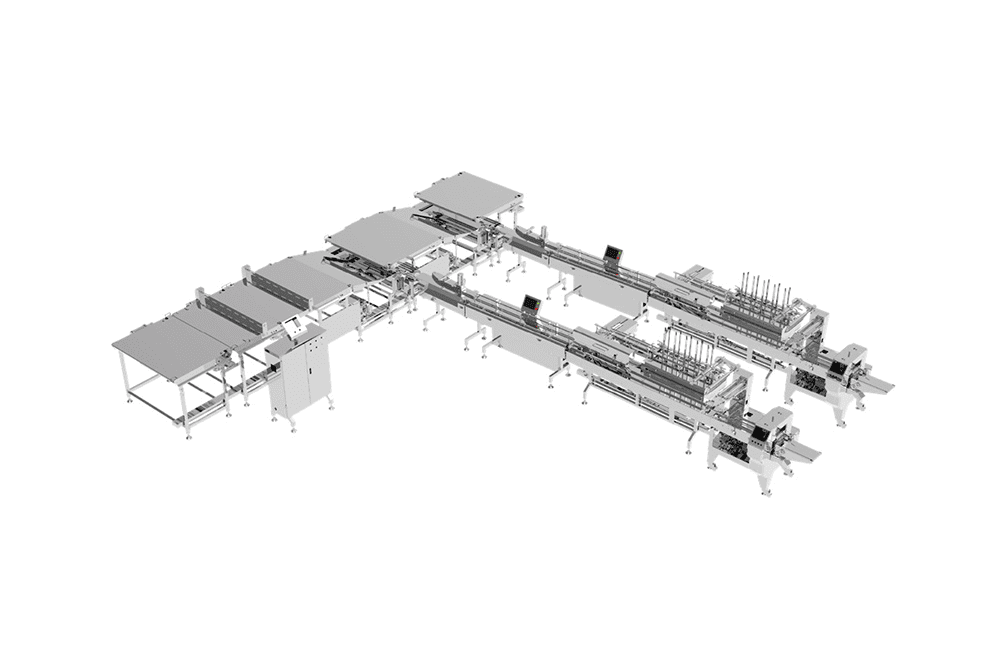

Core Components of a Complete Automated Packaging System

A fully integrated industrial food packaging line is not just a collection of machines; it is a synchronized ecosystem. It typically consists of five key modules:

1. The Feeding and Distribution System

This involves automated packaging equipment for conveying. Whether it’s bucket elevators for granules (like rice or nuts) or screw feeders for powders (like flour or spices), this system automatically sorts and transports raw materials to the scale, eliminating manual scooping and feeding.Smart feeders now auto-adjust flow rates based on the packaging machine's current speed to prevent product jams.

2. Inspection and Quality Control

In the food industry, safety is paramount. Integrated lines incorporate:

- Checkweighers: To reject under/overweight bags automatically and send feedback signals to the filler to auto-correct weight deviations.

- Metal Detectors/X-Ray: To ensure food safety compliance.

- Vision Systems: To verify seal integrity and label accuracy.

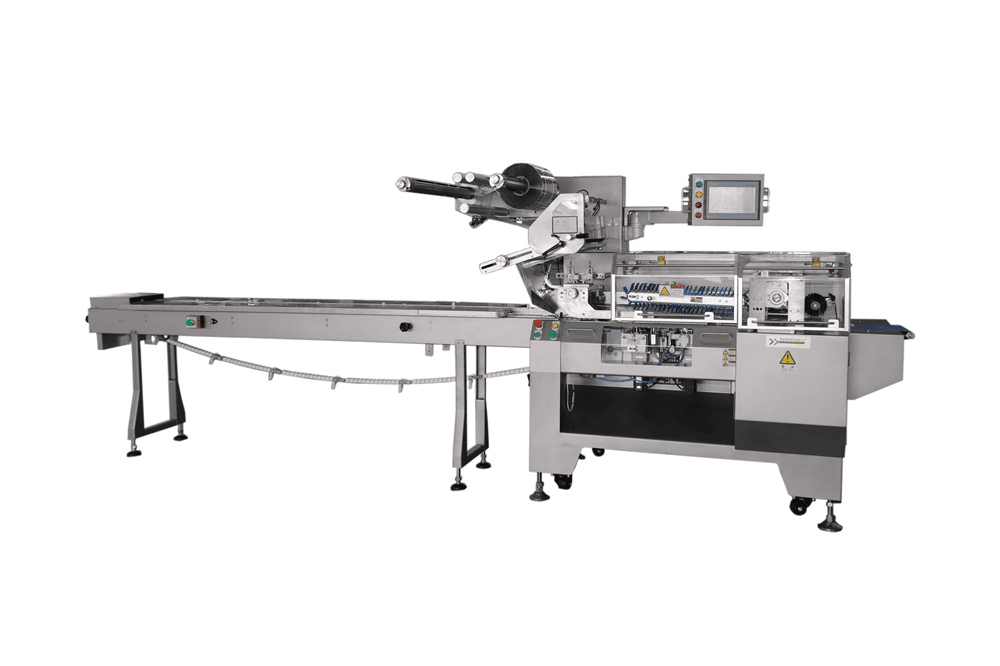

3. The Core Packaging Unit

This is the heart of the line. Depending on the product, this could be a high-speed VFFS machine for snacks or a premade pouch packing machine for sauces. The key here is that the machine "talks" to the feeder and the discharge conveyor to synchronize speed.

4. Secondary Packaging and Warehousing

Once the primary package is sealed, the system handles:

- Case Packing: Robotic arms or drop-packers loading bags into cartons.

- Palletizing: Automatic stacking and wrapping.

- WMS Integration: Connecting with the Warehouse Management System for automated inventory entry.

5. Central Control System (The Brain of Industry 4.0)

Controlled by advanced PLCs (Programmable Logic Controllers) or Industrial PCs, this system ensures all industrial packaging machinery runs in harmony. Beyond basic control, modern systems offer:

Real-time OEE Monitoring: Visualizing performance data instantly.

Recipe Management: One-click changeovers for the entire line.

Remote Diagnostics: Allowing engineers to troubleshoot software issues without visiting the site.

Integration Scenarios: Optimizing Food Packaging Lines

In a factory producing chips or nuts, the automated packaging machine must be tightly integrated with the processing equipment.

- Seamless Handshake: The fryer/seasoning drum feeds directly into the multi-head weigher. The weigher signals the bagger to open only when the product is ready.

- Coding and Labeling Synchronization: The thermal transfer printer is linked to the ERP system, ensuring every batch code is unique and traceable—a requirement for food safety recalls.

- Feedback Loops: If the downstream checkweigher detects a trend of underweight bags, it sends a signal back to the filling machine to auto-adjust the dosing volume without stopping the line.

Through full line integration, these steps achieve a "zero-touch" workflow, significantly boosting the production beat rate.

Best Practices for System Commissioning and Optimization

For agents and distributors selling these systems, understanding the commissioning process is key to customer satisfaction. Successful integration involves:

- Step-by-Step Debugging: Ensure the automatic packaging machine runs perfectly in isolation before linking it to upstream feeders or downstream packers.

- Parameter Unification: Synchronize the speed and signal protocols of all devices. For example, the conveyor speed must match the discharge rate of the bagger to prevent bottlenecks.

- Simulation Testing: Run "dry cycles" and load tests to identify potential jams or timing issues before actual production begins.

- Data-Driven Optimization: Use the data collected by the central control system to identify micro-stops. For instance, if the film changeover takes too long, optimize the splicing process.

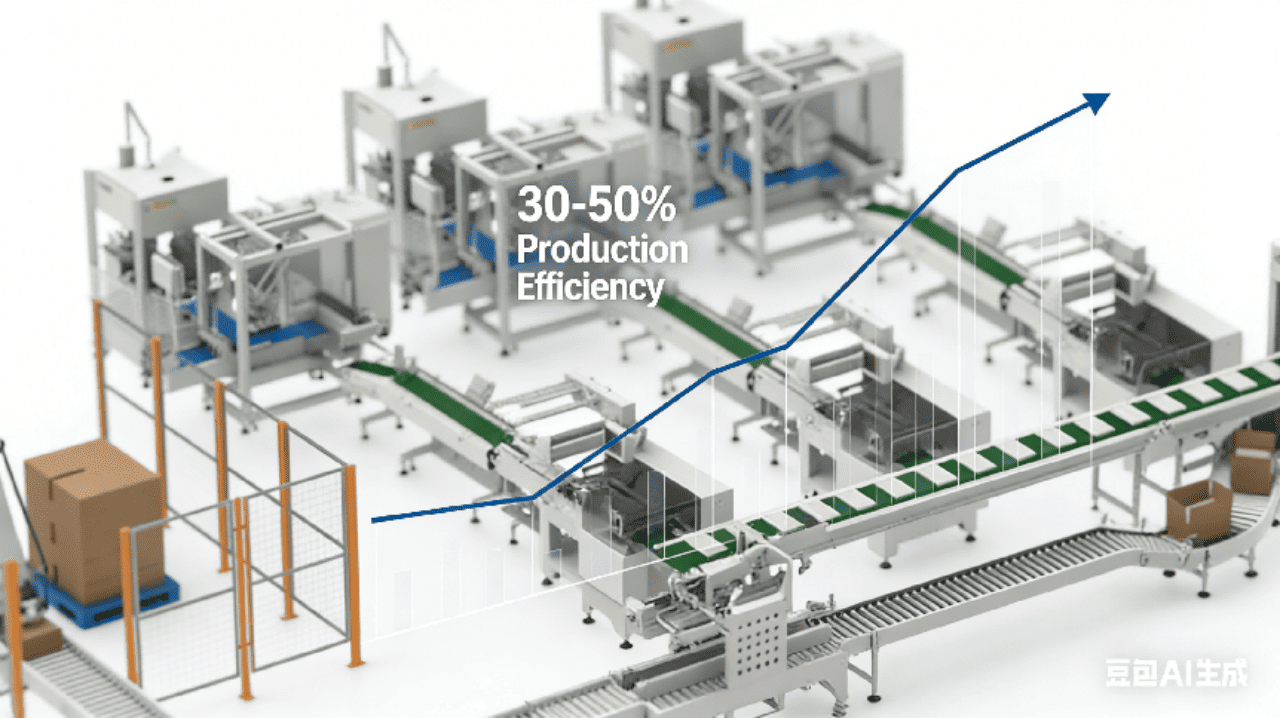

The Economic Value of Integrated Systems - ROI Analysis

While the initial capital expenditure (CAPEX) for a fully automated packaging system is higher than buying a single machine, the long-term Return on Investment (ROI) is compelling for factory owners:

1.Drastic Labor Reduction: A fully integrated line can often replace 4-8 manual workers (feeders, weighers, packers, palletizers). In high-wage regions, this alone justifies the cost.

2.Production Efficiency (+30-50%): Systems run continuously without fatigue. Automated error correction means fewer stops.

3.Quality and Consistency: Eliminating human error reduces giveaway (overfilling) and scrap rates (bad seals).

4.Hygiene and Compliance: Less human contact means higher food safety scores, which is a premium selling point for food brands.

Estimated Payback Period: Typically 1.5 to 3 years, depending on production volume and local labor costs.

Conclusion

The transition from standalone units to integrated lines is the defining characteristic of the 2026 food manufacturing landscape. By eliminating information silos and manual handling, you gain not just speed, but control. Whether you are upgrading a single section or designing a turnkey plant, the key is to choose a partner who understands the entire ecosystem, not just the individual box.

FAQ

Q1: My factory space is limited. Does an integrated line require a huge footprint?

A: Not necessarily. Integrated systems are flexible. We design custom layouts (L-shape, U-shape, or Z-shape) and utilize vertical space with bucket elevators to fit your specific floor plan and minimize the footprint.

Q2: Do I need to replace all my equipment at once? Will I be able to use my existing machines?

A: Not always. If your current machinery, (multi-head weigher etc...) has the capability to work with standard protocols (Modbus) we can also bring that into the new system. We provide your current asset-based hybrid solutions maximization.

Q3: After I place an order, how long until I start making money?

A: A typical project duration is about 3-5 months from design through manufacturing, shipping and installation. We advise beginning your design soon to ensure sufficient time to test and commission.

Q4: In the event of a failure of one of the machines in the line, do I stop the whole production?

A: Not necessarily. Smart buffering works when upstream conveyors slow down or divert product if a downstream unit pauses. The central controller immediately reads the error code for the resolution of the problem quickly and, therefore the whole downtime is minimized.