Flow Wrapping vs. Overwrapping: The 2026 Engineering & Procurement Guide for High-Efficiency Packaging

HFFS Machine Blog

If you're seeking packaging automation solutions, please contact us, and we'll be delighted to offer you the most tailored solution.

What’s the difference between overwrapping and flow wrapping? Flow wrapping and overwrapping are often mentioned together, but they solve different packaging problems. Flow wrapping (HFFS) is typically used as primary packaging to create a sealed pack around the product. Overwrapping is most commonly used as secondary packaging to protect and enhance a carton’s appearance, often adding tamper evidence. This guide explains how each process works, where each one fits best, and how to choose the right solution for your line.

What is Flow Wrapping?

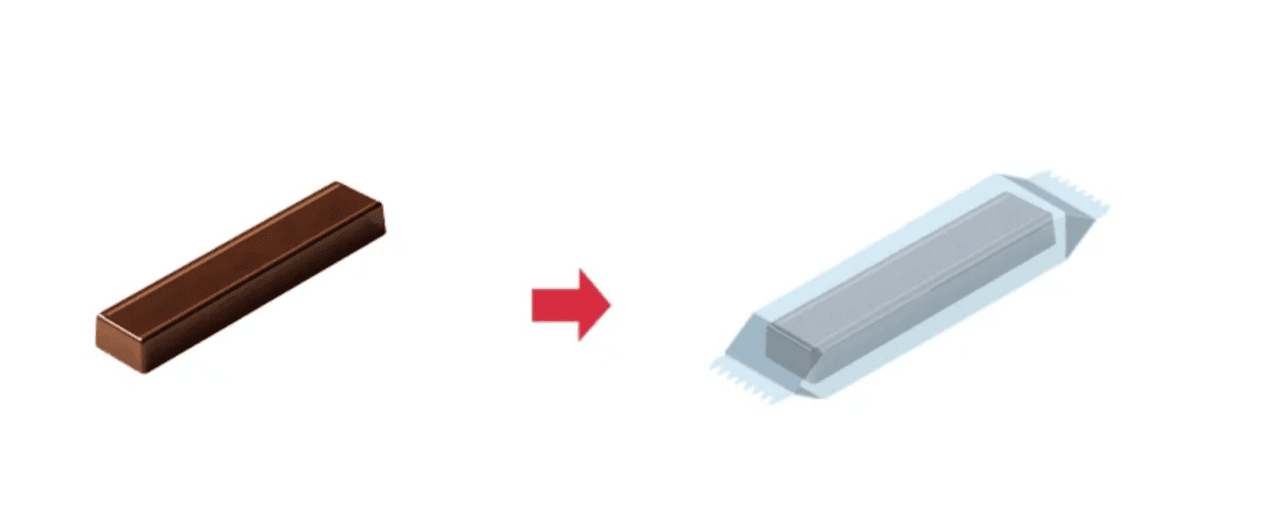

Flow wrapping—also known as Horizontal Form‑Fill‑Seal (HFFS)—wraps a continuous film web around a product and seals it longitudinally and transversely to form individual packs. It is widely used for high‑throughput primary packaging where consistent sealing and product protection are required.

Typical fit: single items, multipacks, irregular shapes, and applications where barrier performance and shelf‑life extension (including MAP) matter.

Pack outcome: a “pillow pack” (or similar fin‑seal format) designed to reduce exposure to moisture, dust, and handling contamination.

Working Process of the Flow Wrapping Machine

Flow wrapping machines can pack products of various shapes. Here is the working process of the flow wrapping machine.

- Infeed: Products are delivered to the wrapper via an infeed conveyor and timed into the forming section.

- Film forming: The film is guided through a forming box/shoulder into a “U” shape around the product path.

- Longitudinal sealing: The film edges are sealed (fin seal or lap seal, depending on configuration) using heat and pressure.

- End sealing & cutting: Transverse jaws seal the ends and separate the continuous tube into individual packs.

- Discharge: Finished packs are transferred to downstream inspection, cartoning, or case packing.

What is Overwrapping?

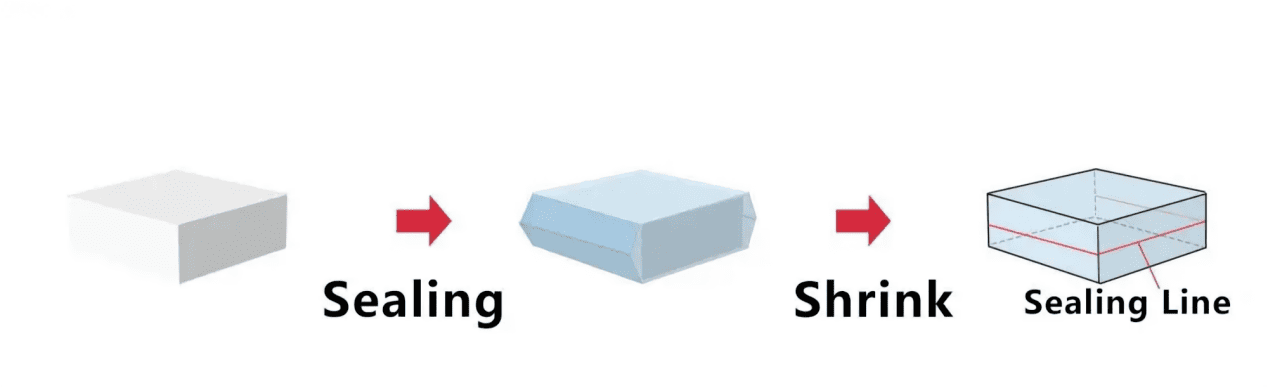

Overwrapping applies a tight film wrap around a rigid carton or box by folding the film at the edges and sealing the overlap. It is primarily used as secondary packaging to improve shelf presentation, protect printed cartons from scuffs, and provide visible tamper evidence.

Typical fit: rigid rectangular cartons (cosmetics, confectionery boxes, tea boxes, tobacco-related cartons, and other premium boxed goods).

Pack outcome: a smooth, high‑clarity finish with consistent corner folds, often combined with tear tape for controlled opening.

Working Process of the Overwrapping Machine

- Product feed: Cartons are conveyed into the wrapping station and synchronized with film delivery.

- Film folding: The film is folded around the carton edges using guides and folding plates (gift‑wrap style corner formation).

- Sealing: The overlap is sealed—typically by a heated sealing bar or pressure‑assisted heat sealing, depending on film type.

- Cooling/setting: The seal is allowed to set to maintain pack integrity and appearance.

- Discharge: Finished cartons move to downstream packing or palletizing.

Key Differences Between Flow Wrapping and Overwrapping: A Technical Comparison

To choose the right machine for your production line, you must look beyond the basic function of "wrapping." Here is a deep dive into the structural, operational, and economic differences between these two technologies.

1. Product Flexibility & Shape Constraints

- Flow Wrapping (The "Universal" Solution): Flow wrappers are the chameleons of packaging. Using an adjustable "forming box" or "shoulder," they can wrap almost anything. Whether your product is round (cookies), irregular (croissants), loose (multipack hardware), or in a tray, flow wrapping handles it. It is forgiving of product size variations and can handle soft products without crushing them.

- Overwrapping (The "Geometric" Solution): Overwrapping is strictly for rigid, cuboid objects. It relies on the product itself to act as a support for the film-folding process. It is ideal for rectangular items like perfume cartons, tea boxes, or CD cases. It cannot handle irregular shapes or soft items that would collapse under the pressure of the folding plates.

2. Sealing Integrity & Barrier Properties

- Flow Wrapping (Hermetic Protection): If your product requires extended shelf life, Flow Wrapping is the superior choice. It creates a hermetic (airtight) seal using heat and pressure on the fin and end seals.

- Why it matters: Because HFFS flow wrapping can achieve a more hermetic seal, it is commonly paired with Modified Atmosphere Packaging (MAP) such as nitrogen or CO2 flushing to reduce oxidation and microbial growth—subject to film barrier and seal validation.

- Overwrapping (Cosmetic Protection): Overwrapping is a "dust cover." It uses spot-sealing on the folded flaps. While it protects against dust, moisture, and odors, it is not airtight. It is not suitable for perishable foods that require a vacuum or gas-flush environment.

3. Material Efficiency & Film Cost

- Flow Wrapping (Higher Consumption, Lower Cost Film): Mechanically, flow wrapping requires a "fin seal" (running along the back) and "end crimps." These seals consume extra film—typically adding 15-20mm to the width and length of the package. However, flow wrappers can run cheaper, thinner films like simple PE or laminates.

- Overwrapping (Lower Consumption, Higher Quality Film): Overwrapping is extremely material-efficient. It cuts the film to the exact dimension of the box with only a 3-5mm overlap, resulting in less plastic waste per unit. However, it requires stiffer, higher-quality films (like double-sided coated BOPP) to fold neatly, which can have a higher cost-per-kilogram than simple flow wrap films.

4. Operational Speed & Changeover Agility

- Flow Wrapping (High Speed): Built for mass production. A standard rotary flow wrapper can easily achieve 200 to 600+ packs per minute (Depending on product length, film type, sealing technology, and feeding method, rotary flow wrappers may run in the hundreds of packs per minute, with high‑performance systems reaching higher outputs in suitable applications).

- Changeover: Very fast. Adjusting the bag length is often done via the HMI touchscreen (servo-driven), and the forming width can be adjusted manually in minutes.

- Overwrapping (Medium Speed): Generally slower due to the complex mechanical folding process, typically running at 40 to 80 packs per minute (Overwrappers are often mechanically constrained by the folding sequence and change parts; many carton applications run in the tens of cartons per minute, while turret systems can be configured for higher outputs.).

- Changeover: Slower. Changing box sizes usually requires replacing physical "change parts" (molds and folding plates), which can take 30-60 minutes.

5. Visual Appeal & Branding

- Flow Wrapping (Industrial Look): While functional, flow wrapping looks "industrial." The visible seams and loose fit can obscure branding. It is viewed as "primary packaging" (meant to be opened and discarded immediately).

- Overwrapping (Premium Look): This is the "Gift Box" standard. The tight, glass-like finish enhances the colors and gloss of the carton underneath. The "Diamond Folds" on the sides are synonymous with luxury.

- Why it matters: Overwrapping is well‑suited to integrating tear tape, which supports controlled opening and provides an additional tamper‑evidence cue for premium boxed goods.

6. Tamper Evidence & Security

- Flow Wrapping: Security comes from the seal strength. To access the product, the consumer must physically tear or destroy the bag. While secure, it lacks the "sophisticated" security features of high-end goods.

- Overwrapping: Overwrapping provides a dual layer of security. First, the tight film proves the product hasn't been opened. Second, the tear tape can be branded or holographic to prove authenticity. Because the film is folded so precisely by machine, it is nearly impossible to manually re-wrap a product to the same standard after tampering, making any interference immediately obvious.

Use the table below as a quick selection reference. Final machine choice should be validated by product trials, required shelf life, and film compatibility.

| Feature | Flow Wrapping (HFFS) | Overwrapping (Tuck & Fold) |

| Best For | Irregular, Soft, or Loose items | Rigid, Rectangular Boxes |

| Sealing | Hermetic (Air-tight / Gas Flush capable) | Dust & Moisture Proof (Not Air-tight) |

| Speed | High (60 - 600+ ppm) | Medium (40 - 80 ppm) |

| Film Usage | Higher (Due to fin seals & crimps) | Lower (Tight fit, minimal overlap) |

| Aesthetics | Standard / Industrial | Premium / Gift-like |

| Changeover | Fast & Flexible | Slow (Requires Mold Changes) |

Flow Wrapping vs. Overwrapping: Industry Applications & Use Cases

Choosing between Flow Wrapping and Overwrapping often comes down to one fundamental question: Is your priority Product Preservation (Primary Packaging) or Brand Presentation (Secondary Packaging)?

Here is a breakdown of where each technology dominates in the global market.

1. Applications for Flow Wrapping (HFFS)

The "Preservation & Protection" Specialist Flow wrapping is predominantly used for primary packaging, meaning the film is in direct contact with the product. It is the go-to solution for industries that require high-speed output, hygienic barriers, and shelf-life extension.

Food & Bakery (The Largest Sector)

Products: Biscuits, chocolate bars, croissants, bread, frozen pizzas, and ice cream bars.

Why Flow Wrap?

- Freshness: It creates a hermetic seal. When combined with Gas Flushing (MAP), it keeps bakery items soft and prevents mold for weeks.

- Grease Resistance: The film contains oils and crumbs effectively, which a cardboard box alone cannot do.

Medical & Pharmaceutical

Products: Syringes, IV kits, blister packs, diagnostic test kits, and surgical masks.

Why Flow Wrap?

- Sterility: Medical-grade paper/film creates a bacteria-proof barrier.

- Safety: The seal is robust; if the pack is breached, it is immediately visible, ensuring patient safety.

Hardware & Industrial Components

Products: Bearings, hinges, switches, plumbing fittings, spare part kits.

Why Flow Wrap?

- Organization: Keeps loose multi-part kits (e.g., screws + wall plugs) together.

- Protection: Prevents oxidation (rust) and protects lubricated parts from drying out or collecting dust.

Fresh Produce

Products: Tray-packed peppers, tomatoes, leafy greens, and herbs.

Why Flow Wrap?

- Breathability: Machines can run perforated films that allow the product to "breathe," extending freshness without suffocating the vegetables.

2. Applications for Overwrapping

The "Presentation & Premium" Specialist Overwrapping is almost exclusively used for secondary packaging of rigid, rectangular containers. It is the standard for industries where shelf appeal, brand image, and tamper evidence are critical drivers of sales.

Cosmetics & Perfumery (The "Luxury" Sector)

Products: Perfume cartons, facial cream boxes, makeup palettes, soap bars.

Why Overwrap?

- The "Gift" Effect: The diamond-fold finish mimics a hand-wrapped gift. It adds a high-gloss shine that makes the colors on the carton pop.

- Protection: It prevents the expensive carton from getting scratched or scuffed during shipping.

Tobacco & E-Cigarettes

Products: Cigarette packs, vape cartridge boxes, shisha molasses boxes.

Why Overwrap?

- Moisture Control: It keeps the tobacco moist and the aroma contained within the pack.

- Convenience: The integration of a Tear Tape is an industry standard for easy opening.

Tea, Coffee & Confectionery

Products: High-end tea chests, boxes of chocolates (pralines), and chewing gum multipacks.

Why Overwrap?

- Aroma Barrier: It locks in the delicate scent of tea or chocolate, preventing contamination from outside odors (like detergent in a supermarket aisle).

- Bundling: It is often used to bundle 5 or 10 small packs together (e.g., gum) for retail sale.

Media & Stationery

Products: Playing cards, sticky note pads, envelopes, DVD/Blu-ray cases.

Why Overwrap?

- Integrity: It keeps multi-piece items (like a deck of cards) tightly secured so they don't shift or fall out.

3. The "Hybrid" Scenario: When You Need Both

For many manufacturers, the question isn't "Which one?" but "In what order?" Many production lines utilize both technologies to achieve maximum protection and presentation.

The Biscuit Line Example:

- Primary Stage (Flow Wrap): Individual cookies are flow-wrapped to keep them fresh and hygienic.

- Secondary Stage (Cartoning): The flow-wrapped cookies are placed into a cardboard retail box.

Final Stage (Overwrap): The retail box is overwrapped to seal the carton and provide a premium finish.

Summary: Which Application Fits You?

| If your product is... | And your goal is... | You need: |

| Loose, Irregular, or Edible (Cookie, Bread, Syringe) | Freshness, Hygiene, Speed | Flow Wrapping |

| A Rectangular Box/Carton (Perfume, Tea, Cigarettes) | Shelf Appeal, Gloss, Tamper Proofing | Overwrapping |

| A Multipack of Loose Items (Screws, Candy) | Containment, preventing loss | Flow Wrapping |

| A Bundle of Small Boxes (10 packs of gum) | Logistics, replacing master cartons | Overwrapping |

Conclusion: Which Solution Fits Your Brand?

By now, the distinction should be clear: use Flow Wrapping when you need speed, versatility, and airtight freshness for food or hardware. Choose Overwrapping when you need to transform a standard carton into a luxury, shelf-ready item for cosmetics or tea.

Still unsure which technology offers the best ROI for your specific product? Don't guess—test. At Soontrue, we specialize in both technologies. Contact our engineering team today to run a sample test and discover the perfect packaging strategy for your business.

Frequently Asked Questions (FAQ)

Q1: Can one machine perform both Flow Wrapping and Overwrapping?

A: No. The mechanical principles are fundamentally different. Flow wrapping forms a tube from a roll of film (HFFS), while overwrapping uses a "tuck and fold" mechanism similar to manual gift wrapping. If your production line requires both (e.g., flow-wrapped cookies inside an overwrapped box), you will need two separate machines or an integrated packaging line.

Q2: Which packaging method is more sustainable/eco-friendly?

A: It depends on your sustainability goals.

- Material Waste: Overwrapping is more efficient as it cuts film to the exact box size with minimal overlap, creating less plastic waste per unit.

- Recyclability: Flow Wrapping is currently leading in the adoption of recyclable mono-materials (like pure PE) and paper-based films, whereas overwrapping typically requires stiffer films (like BOPP) to maintain the fold structure.

Q3: Is a Flow Wrapper cheaper than an Overwrapping Machine?

A: Generally, yes. Entry-level flow wrappers are often less expensive and easier to set up for small businesses. Overwrapping machines are precision instruments with complex cam systems and folding plates, often commanding a higher initial capital investment. However, for high-volume production, the lower film cost of overwrapping can offer a better long-term ROI.

Q4: Can I print branding designs on Overwrapping film?

A: Yes, but it requires high precision. While flow wrapping easily handles registered print designs (logos centered on the pack), overwrapping is often used with clear transparent film to show the carton design underneath. If you want to print on overwrapping film, the machine requires a "spot calibration" system to ensure the logo aligns perfectly with the box face.

Q5: Which machine is better for heat-sensitive products (like chocolate)?

A: Flow Wrapping is generally safer. It offers "Cold Seal" options where the film seals via pressure and adhesive rather than heat. Even with heat sealing, the heat is applied to the fin, away from the product. Overwrapping requires heat plates to seal the folded flaps against the box, which could transfer heat to the product if not carefully controlled.