Top Film Loader vs. Bottom Film Loader Flow Wrappers: Which is Right for Your Product?

HFFS Machine Blog

If you're seeking packaging automation solutions, please contact us, and we'll be delighted to offer you the most tailored solution.

Imagine this scenario: You’ve invested heavily in a new packaging line, expecting efficiency. Instead, you’re dealing with a production nightmare. Your soft cakes are getting crushed by the machine’s pushers, cream is smearing all over the conveyor belt, and your team is stopping the line every hour for cleaning.

If this sounds familiar, the problem likely isn't the quality of your machine—it’s the configuration. You might be using a standard Top Film Flow Wrapper when your specific product actually demands an Inverted (Bottom Film) Wrapper.

In this guide, we’ll help you look at your product’s physical properties to ensure you choose the right machine setup for your production line.

1. The Standard Choice: Top Film Loader Flow Wrappers

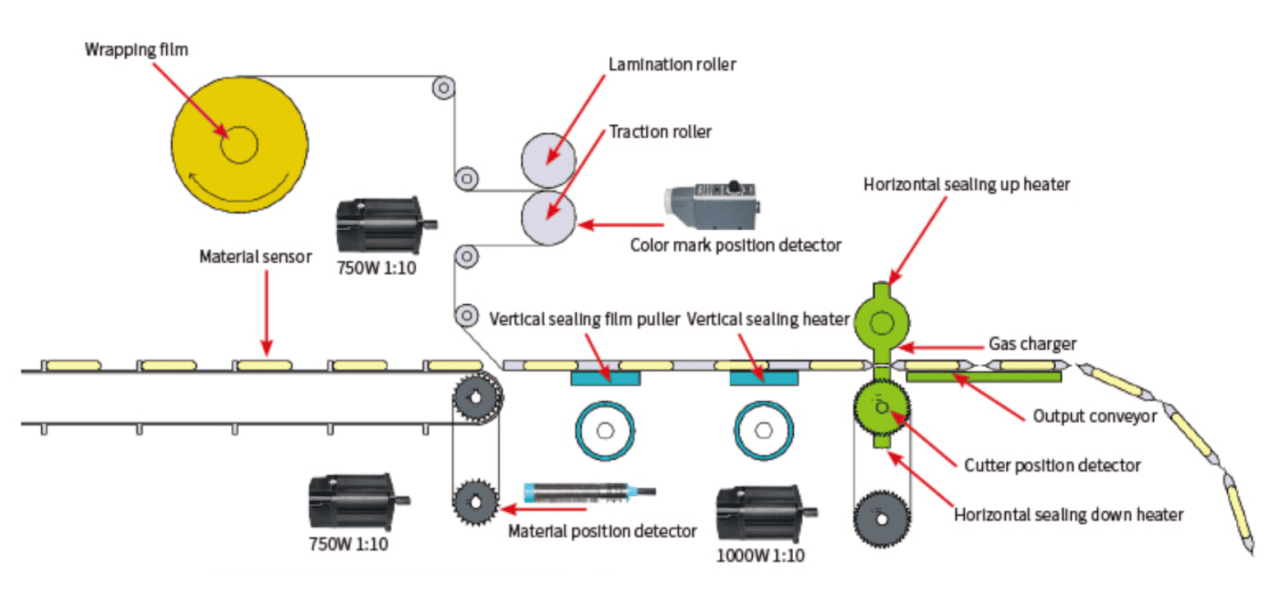

When you picture a "pillow packing machine," this is likely what you see. In this configuration, the film reel is mounted above your product.

How It Works

- The Process: You place your products on a metal chain conveyor.

- The Movement: A mechanical "pusher" (lug chain) comes up behind your product and physically pushes it into the forming tube.

- The Seal: The machine creates the fin seal on the bottom of your pack.

When Should You Choose This?

You should opt for a Top Film Loader machine if you are packaging products that are rigid, consistent, and dry.

- Are you packing biscuits, chocolate bars, or hardware? This is your best choice.

- Are your products in trays? This is the industry standard for you.

Why you’ll love it: It’s generally faster and hides the seal underneath the pack for a cleaner look on the shelf.

What to watch out for: If your product is sticky or fragile, the pushers might damage it or get jammed.

2. The Gentle Alternative: Inverted (Bottom Film Loader) Flow Wrappers

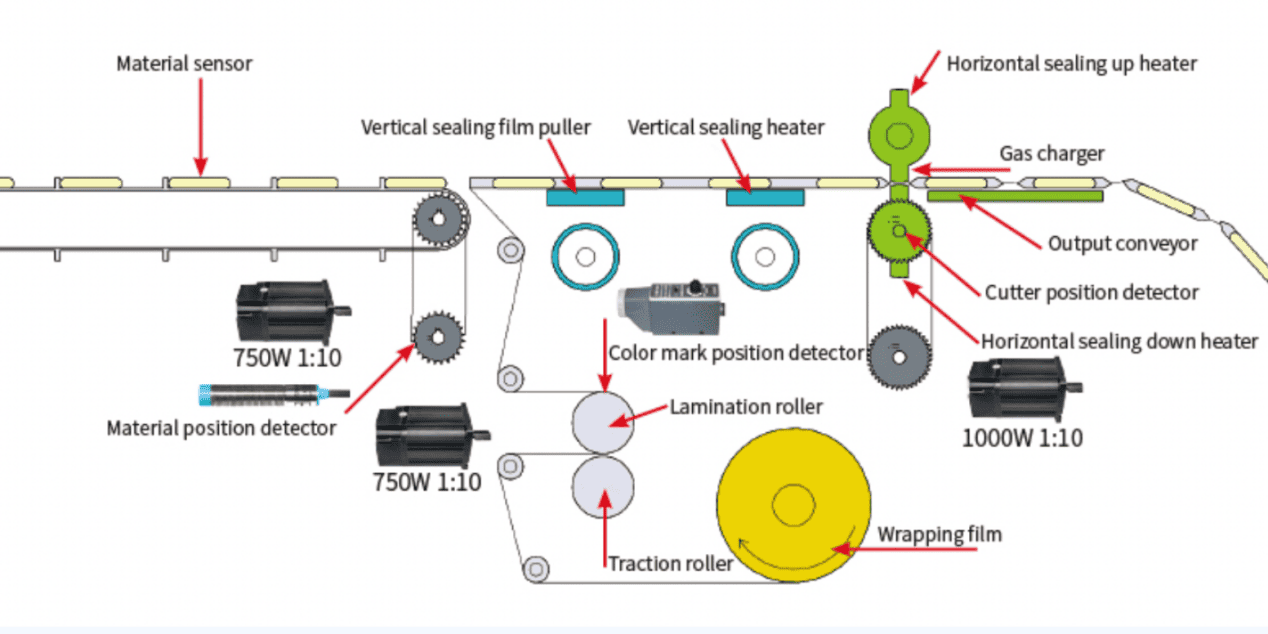

Also known as "Bottom Feed" wrappers, these machines flip the script. The film reel is mounted below your product flow.

How It Works

- The Process: The film comes up from underneath.

- The Movement: Instead of being pushed, your product sits directly on top of the film. The film acts as a conveyor belt, carrying your product forward gently.

- The Seal: The machine creates the fin seal on the top of your pack.

When Is This Your Best Option?

If you struggle with difficult-to-handle items, this configuration is a game-changer for your operations.

- Is your product soft? (e.g., Tortillas, sponge cakes). Since nothing pushes it, it won't get squashed.

- Is your product sticky? (e.g., Fruit bars, gummies). Because your product sits on the film and doesn't touch the metal machine bed, you won't have to stop for cleaning nearly as often.

- Are you packing loose items? (e.g., A kit of 3 sausages or loose vegetables). The film carries them as a group, keeping your pack organized.

Why you’ll love it: It drastically reduces your waste and downtime caused by jams or cleaning.

What to watch out for: The seal line is visible on top (though we can make it very discreet).

3. Your Quick Decision Matrix

Not sure which one fits your factory? Use this cheat sheet to compare:

| Feature | Standard (Top Film Loader) | Inverted (Bottom Film Loader) |

| Film Reel Position | Top | Bottom |

| How Your Product Moves | Pushed by a Lug Chain | Carried by the Film |

| Where the Seal Goes | Bottom (Hidden) | Top (Visible) |

| Good for Your Sticky Items? | No (Might stick to the bed) | Yes (Excellent) |

| Good for Your Soft Items? | No (Risk of crushing) | Yes (Gentle) |

| Sanitation for You | Standard | High (Less contact) |

4. Ask Yourself These 3 Questions

Still undecided? Look at your product right now and ask yourself these three questions.

Question 1: "Is my product sticky?"

If you are producing sticky fruit bars or marinated items, a standard machine will frustrate you. Your product will drag against the metal in-feed bed. Your Move: Choose an Inverted Wrapper. Let the film carry the sticky product so it never touches the machine parts.

Question 2: "Can my product take a hit?"

Imagine poking your product with your finger. Does it dent? If a mechanical pusher hits your soft croissant, it will deform. But if a pusher hits a hard cracker, it’s fine. Your Move: If your product deforms under pressure, you need the gentle handling of an Inverted machine. If it’s solid, stick with Top Film Loader for higher speeds.

Question 3: "Is my product uniform?"

Are you packing single, identical blocks of soap? Or are you packing variable vegetables like celery? Your Move: Loose or variable items are hard to "push" because they separate or roll away. An Inverted Wrapper stabilizes them on the film, giving you a perfect pack every time.

5. Real Results from Factories Like Yours

The Tortilla Challenge

One of our clients was struggling with flour tortillas sticking to their standard machine plates, forcing them to stop production every 20 minutes.

The Fix: They switched to a Soontrue Inverted Flow Wrapper. By letting the tortillas ride on the film, they cut downtime by 80% and virtually eliminated waste.

The Vegetable Solution

A farm needed to pack celery stalks of different sizes. Standard pushers required constant manual adjustment.

The Fix: An Inverted machine allowed them to place variable-sized celery directly onto the film. The machine automatically adjusted the bag length, giving them the flexibility they needed.

Choosing between a Top Film and Bottom Film Loader flow wrapper isn't just about the machine specs—it's about your product's success.

- Choose Top Film Loader if you need speed for rigid products.

- Choose Bottom Film Loader (Inverted) if you need flexibility for sticky or soft products.

If Still not 100% sure?You don't have to guess. Send us your product samples! Our engineers will run a free test on both machine types using your actual products. We will send you a video report so you can see exactly how your product performs before you spend a dime.

Contact Us Today to Schedule Your Free Test Run

Frequently Asked Questions (FAQ)

Q1: Is an Inverted (Bottom Film Loader) Wrapper slower than a Standard Top Film machine?

A: Generally, yes. Standard Top Film machines use mechanical pushers, allowing for very high speeds (often 300-500 packs/min). Inverted machines rely on the film to carry the product, so speeds are typically lower (80-200 packs/min) to prevent film stretching or product slippage. However, for sticky or fragile products, the effective output of an Inverted machine is often higher because it eliminates downtime caused by jams.

Q2: Since the seal is on top of the pack with an Inverted machine, will it look ugly?

A: Not at all. While the fin seal is on top, modern machines create a very tight, neat seal. For many products (like multipack vegetables, wet wipes, or meat trays), this is the industry standard and perfectly acceptable to consumers. If aesthetics are a major concern, the seal can easily be covered by a label.

Q3: Can I pack both "soft" and "hard" products on the same Inverted machine?

A: Yes! This is a huge advantage of Inverted wrappers. They are highly versatile. While designed for difficult/soft products, they handle rigid items (like trays or hard biscuits) perfectly well. If your factory runs a mix of products, an Inverted machine is often the safer, more flexible investment.

Q4: Can I use Gas Flushing (MAP) with an Inverted Flow Wrapper?

A: Absolutely. Both machine types can be equipped with gas flushing. If you need high hermetic seals for extended shelf life (e.g., for bakery or meat), we recommend choosing an Inverted wrapper equipped with Box Motion (Reciprocating) jaws to ensure a long enough dwell time to seal the gas in.

Q5: Do I need special packaging film for a Bottom Film machine?

A: No, it uses the same materials (OPP, BOPP, laminates) as standard machines. The only difference is the winding direction of the reel. If you have stock film for a top film machine, you might need to ask your film supplier to adjust the winding direction for future orders, but this is not a technical barrier.