Strategic trends that will influence your decisions in flexible packaging machinery in 2026

Industry news

If you're seeking packaging automation solutions, please contact us, and we'll be delighted to offer you the most tailored solution.

A comprehensive guide exploring how automation, sustainability, and regionalization will transform your production line

Introduction: The Automation Imperative

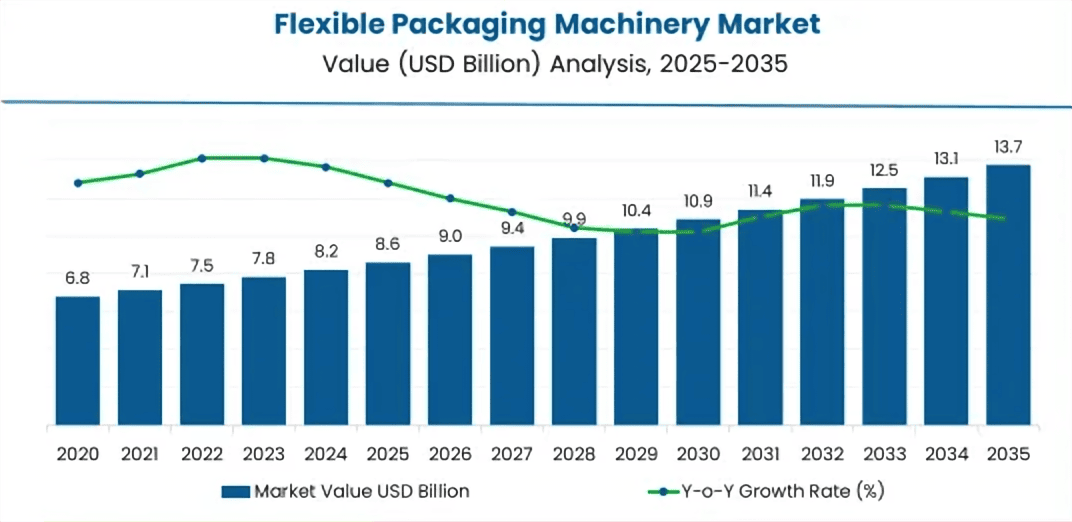

Your packaging lines are nearing a turning point. The segment is expanding, but for you this isn’t really about the size of the market — you’re talking about a basic reorganization in how you package your products.

You've probably relied on rigid formats—glass jars, metal cans, and hard plastics for years. You recognize that the tide has turned irrevocably toward flexible packaging. Pouches and films give you enchantingly tangible benefits: they slice your logistics costs, reduce your carbon emissions, and let your product stand out on the shelf.

That is a huge challenge for your factory floor, but it poses a powerfully positive energy that your machinery must transform into. The mechanical equipment of yesteryear that you have sitting in your plant today was built on a different age — an age of long runs, thick forgiving…

Looking out to 2026, the disconnect between your legacy systems and modern market requirements is growing. It sounds like you’re in a “perfect storm”:

1.Sustainability mandates requiring you to run difficult-to-seal eco-films.

2.Labor shortages making it impossible to staff your manual packing lines.

3.Data demands from your retailers requiring real-time traceability.

This article discusses the four strategic pillars that will determine your success in 2026 – Green Engineering, Industry 4.0 Intelligence, Hyper-Agility, and Global Market Dynamics. These trends at this point aren't a choice for you to ignore—they are what you must live with.

Trend 1: Your "Green" Engineering Challenge

For you, sustainability is no longer just a marketing buzzword; it is an engineering constraint that must reshape how you buy machines. By 2026, your major retail partners will likely demand 100% recyclable packaging. This forces you to transition from forgiving multi-layer laminates to Mono-materials (e.g., all-PE or all-PP) and paper-based films.

The Technical Hurdle You Face

Your traditional heat-sealing jaws work well with multi-layer laminates because the wide operating window protects you from errors. However, with mono-materials, you have a very narrow thermal window. If your temperature is too high, the film melts onto your jaws; if it's too low, your seals leak, and you face product recalls.

Your 2026 Solution

To handle these sensitive materials without slowing down your production, you need to look for two key technologies:

1.Ultrasonic Sealing Technology: Unlike your current heat bars, ultrasonic sealing generates heat from the inside out. This allows you to achieve hermetic seals even through product dust or liquid, and it is far gentler on your eco-friendly films. By 2026, you should consider this a standard requirement for your premium lines.

2.Advanced PID Temperature Control: You need to move away from simple on/off heaters. Modern machines use sophisticated PID loops that ensure your seal jaw temperatures remain stable within ±1°C. This precision is the only way you will successfully run paper-based films without burning them.

Strategic Takeaway: When you sign that next purchase order, verify the machine's "Future-Readiness." If you buy a machine today that can only run standard laminates, you are risking a "stranded asset" as regulations tighten around you.

Trend 2: Industry 4.0 & Your "Smart" Packaging Line

The era of your purely mechanical packaging line is ending. Your factory floor in 2026 must be digital, connected, and intelligent. You need to phase out cam-driven systems in favor of fully servo-driven architectures.

Move From Reactive to Predictive Maintenance

Currently, your maintenance team likely fixes a machine only after a bearing fails, costing you expensive downtime. Industry 4.0 changes your script to Predictive Maintenance.

By integrating sensors into the servo motors, your modern system can detect anomalies weeks before a failure occurs. Imagine your machine effectively telling you: "My jaw pressure is deviating by 5%; please inspect the bearing during your next scheduled break."

Remote Diagnostics and Connectivity

You should demand secure remote access modules from your OEM. This allows technical experts to troubleshoot your software or servo parameters from thousands of miles away, reducing your downtime from days to mere minutes.

Furthermore, you need to integrate your VFFS/HFFS machine with your MES and ERP systems. This connectivity gives you real-time OEE (Overall Equipment Effectiveness) data, exposing exactly where your micro-stops are occurring so you can optimize your line based on data, not guesswork.

Trend 3: Hyper-Flexibility and Your "SKU Explosion"

You are likely feeling the pressure of the "SKU Explosion" driven by e-commerce. Where you once ran the same 500g bag for three days straight, you must now switch between 50g samples, 200g retail packs, and 1kg club-packs multiple times a shift.

The Death of Your 2-Hour Changeover

In 2026, if your machine requires tools, wrenches, and two hours of mechanical adjustment to change formats, it is a liability. You need Tool-less Changeovers.

Modern machines utilize HMI recipes. Your operator simply selects "Product B" on the touchscreen, and the servos automatically adjust tension and speed. You should look for "quick-lock" mechanisms that allow your team to complete physical changes in under 10 minutes.

Hybrid Machine Architecture

You should also consider hybrid systems capable of producing multiple bag styles (Pillow, Gusseted, Quad-seal) on a single frame. This versatility allows you to say "yes" to diverse client requests without investing in three separate machines.

Trend 4: Automation to Counter Your Labor Shortages

Your most immediate headache is likely the global labor crisis. Finding reliable staff to perform repetitive manual packing is becoming increasingly difficult and expensive for you.

Look Beyond the Wrapper

You need to expand your definition of a "packaging system." It is no longer enough for you to buy a standalone flow wrapper. You must aim for Full Line Integration.

Invest in systems that seamlessly connect:

1.Your Primary Packaging: The VFFS or Flow Wrap machine.

2.Your Secondary Packaging: Robotic case packers that automatically group and load your bags.

3.Your Tertiary Packaging: Palletizers that wrap your pallets for shipment.

Cobots (Collaborative Robots)

Where you cannot fully automate, bring in "Cobots." Unlike traditional robots that need cages, Cobots work safely alongside your staff, handling tasks like loading film or inspecting seals. This gives you the flexibility of human judgment with the endurance of a machine.

Global Market Dynamics: Where You Fit In

Understanding where the market is growing helps you understand your supply chain and your competition.

1. If you operate in or source from APAC: You are in the world's powerhouse region. The rising middle class in China and India is driving your demand. Note that manufacturing hubs are shifting; while China remains central, you might find increasing opportunities to establish production in Vietnam or Thailand.

2. If you are looking at China’s Role: Realize that China is shifting from "Volume" to "Value." You are no longer just buying low-cost mechanical gear from there. Chinese OEMs are now exporting high-tech, servo-driven systems that rival European performance. If you are in the "Pre-made Dish" (Yuzhicai) sector, look for local innovations in vacuum and MAP technologies.

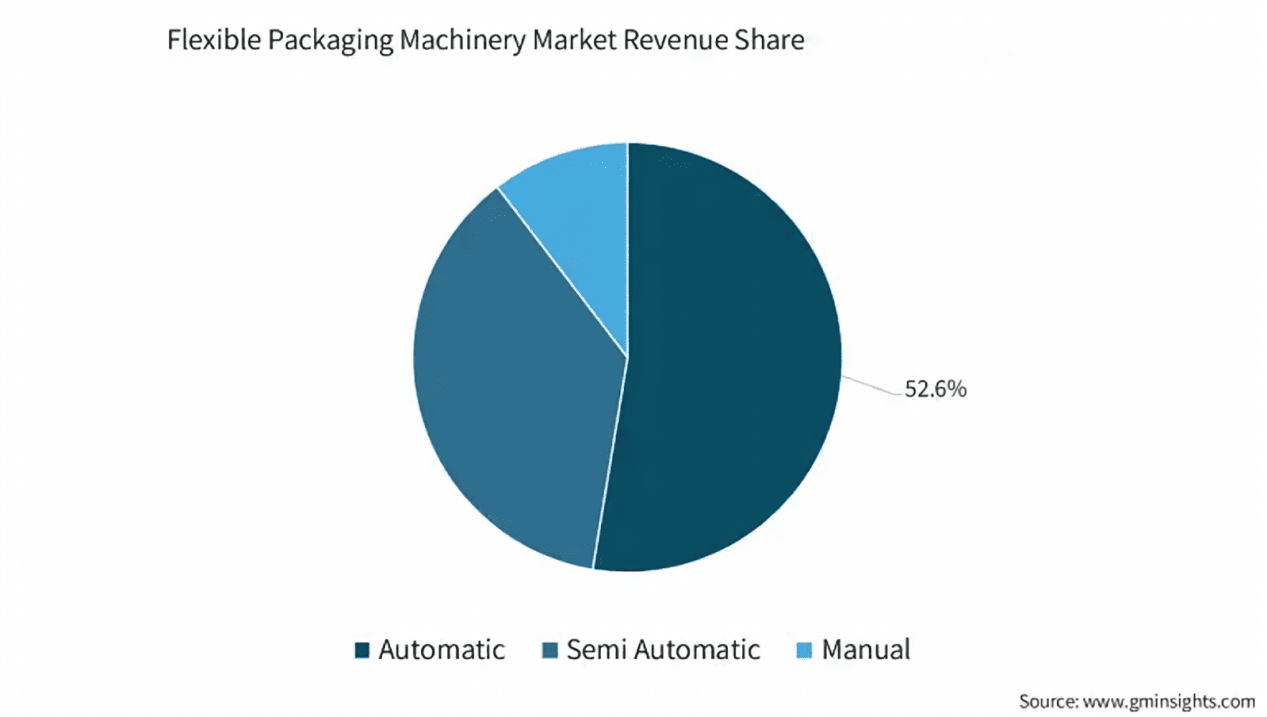

3. If you are Reshoring to North America: You face an "Automation Gap." High labor costs mean you cannot afford semi-automatic lines. You must prioritize fully automated, "hands-free" turnkey lines. Ensure your suppliers meet UL/CSA standards to avoid compliance headaches.

4. If you are selling to Europe: You are in the "Sustainability Lab." Regulatory pressure here is highest. If you need technology that handles paper film efficiently, look to European standards, as they are leading the R&D in this space.

Conclusion: Your Investment Checklist for 2026

For you, upgrading equipment is no longer just about increasing output speed—it is about future-proofing your business.

Before you sign a contract, evaluate your potential machinery partners against this 2026 Investment Checklist:

1.Material Agility: Can this machine seal the sustainable films you will need tomorrow, or is it limited to the laminates of yesterday?

2.Digital Maturity: Is it IIoT-ready? Can it give you real-time OEE data?

3.Changeover Speed: Does it support tool-less changeovers to handle your high-mix SKU portfolio?

4.Integration Capability: Can it talk to your downstream case packers to reduce your manual labor?

5.Supplier Support: Does the OEM have the remote support infrastructure to guarantee your uptime?

Automation is your investment in resilience. By aligning with these trends, you transform your packaging line from a cost center into your competitive advantage.

Frequently Asked Questions: Upgrading Your Packaging Line

Q1: Can your existing legacy VFFS machine be retrofitted to run sustainable mono-materials?

A: In most cases, your legacy machines will struggle due to narrow heat-sealing windows. While you can try mechanical retrofits, they often fail to achieve high speeds. To run sustainable films efficiently, investing in a modern machine with Ultrasonic Sealing is typically more cost-effective for you in the long run.

Q2: What is the typical ROI timeline for your fully automatic packaging line?

A: If you are replacing 4-6 manual laborers with a high-speed line, you can typically expect an ROI within 12 to 18 months. This includes your savings from labor, reduced material waste, and increased output.

Q3: How does "Predictive Maintenance" actually save you money?

A: It moves you from "fixing broken parts" to "servicing healthy parts." By detecting abnormalities early, the system alerts you to replace a part during a scheduled break rather than suffering a 4-hour breakdown during a rush order. This can reduce your annual maintenance costs by 25-30%.

Q4: You have many SKUs. How fast is the changeover on a modern machine?

A: You should expect "Tool-less Changeovers." With servo-driven adjustments, your operator can complete a format change in under 10 to 15 minutes, compared to the 1-2 hours you might be used to.

Q5: Is it better for you to buy a standalone machine or a fully integrated system?

A: If you anticipate growth, a fully integrated system is superior. It eliminates bottlenecks and ensures a single control standard for your whole line. This "Turnkey" approach simplifies your life, as you only deal with one accountable partner for support.

Don't let your factory fall behind in 2026. Contact our engineering team today for a free audit of your current line