The Complete Guide To Biscuit Packaging Machine: Efficiency, Protection and ROI

Packaging Knowledge Hub

If you're seeking packaging automation solutions, please contact us, and we'll be delighted to offer you the most tailored solution.

In the competitive world of bakery production, the snap of a biscuit is the noise of success. That texture is a challenge to maintain from the oven band to the hand of the consumer.

For processors, distributors, and co-packers in the food production plant, the packaging line is often the bottleneck. Poor equipment not only slows production, but it can result in higher rates of breakage, reduced shelf life, and increased film cost.

This is not your basic guide, oh no. We cover the design, materials and technology and process solutions for biscuit packaging machines so that you can select the best and highest performing solution that will maximize your line efficiency for Overall Equipment Effectiveness (OEE).

Why Advanced Biscuit Packaging Automation is a Critical Investment

Biscuit packing machine is not just a wrapping machine but also a preserving mechanism.Whether you make hard dough biscuits, soft cookies or cream-filled sandwich, the line that you chose will deliver three important ROI strapping functions!

- Minimizing Product Giveaways & Waste: Modern systems with intelligent feeding and "No-Product-No-Packaging" features ensure you never wrap empty air or cut through a misaligned biscuit.

- Extending Shelf Life (MAP): Biscuits are hygroscopic (moisture-absorbing) and high in fat. Advanced machines integrate Nitrogen Flushing (Modified Atmosphere Packaging) to prevent oxidation and sogginess.

- Brand Protection: In a crowded retail aisle, pack integrity is paramount. A machine that delivers consistent seal quality ensures your brand is associated with freshness, not stale crumbs.

Comparing Biscuit Packaging Machine Types: Which Fits Your Line?

Selecting the right architecture depends on your product fragility, shape, and desired output speed.

1. Horizontal Flow Wrappers (HFFS)

The Industry Standard for Speed and Versatility

This is the workhorse of the biscuit industry. The product travels horizontally on a conveyor, and film is wrapped around it, sealed at the bottom (fin seal) and ends.

Best For: Trays, stacks of biscuits, or individual cookies.

Key Configuration – Rotary vs. Box Motion:

Rotary Jaws: The sealing jaws rotate continuously.

- Pros: Extremely high speed .

- Cons: Shorter sealing time, less airtight.

Box Motion (Reciprocating) Jaws: The jaws move in a square motion, traveling with the product to seal.

- Pros: Longer dwell time creates a hermetic (airtight) seal essential for gas flushing.

- Cons: Slightly slower speeds.

Procurement Tip: If you need long shelf life for export, choose Box Motion. If you need speed for local school snacks, choose Rotary.

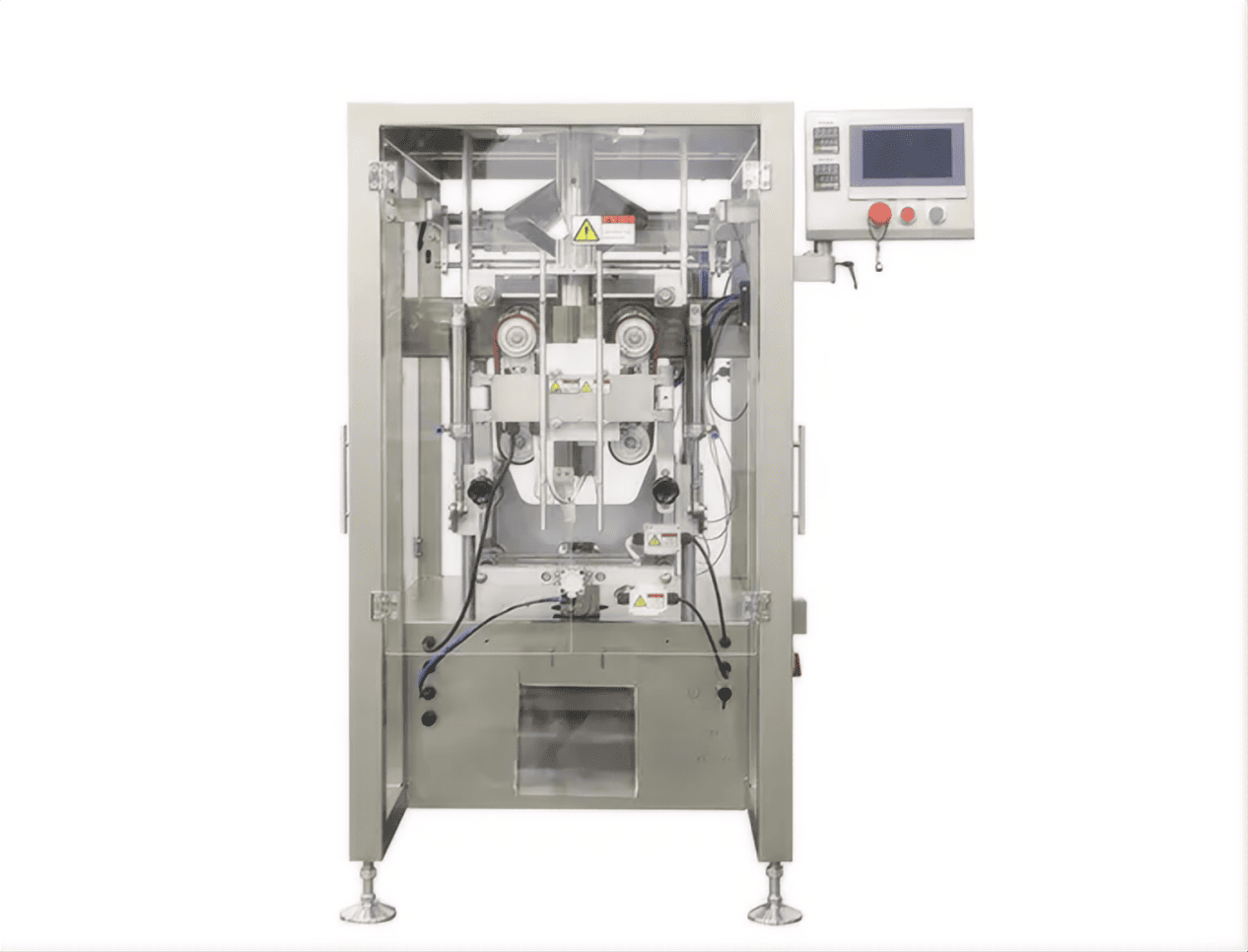

2. Vertical Form Fill Seal (VFFS) Machines

The Solution for Loose or Mini Snacks

Instead of wrapping a neat stack, VFFS machines drop the product into a forming tube.

Best For: "Dump packs" of mini cookies, animal crackers, or broken biscuit assortments.

- Pros: Small footprint and lower capital cost.

- Cons: Not suitable for fragile, large biscuits as the drop can cause breakage.

3. Rotary Premade Pouch Machines

The Premium Retail Solution

For high-end cookies, consumers prefer resealable stand-up pouches (Doypacks). This machine picks up a pre-made bag, opens it, fills it, and seals it.

Best For: Premium chocolate chip cookies, keto snacks, and gift packs.

- Pros: Superior shelf presence and zipper integration.

- Cons: Higher cost per bag compared to roll stock film.

Decision Matrix: Flow Wrapper vs. VFFS vs. Pouch Machine

Use this table to align your choice with your production goals.

| Feature | Horizontal Flow Wrapper (HFFS) | Vertical (VFFS) | Rotary Premade Pouch |

| Primary Product | Trays, Stacks, Single Cookies | Mini Cookies, Loose Snacks | Premium/Gourmet Cookies |

| Speed Potential | Very High | High | Medium |

| Protection Level | High (Tray support available) | Medium (Drop impact risk) | High (Strong barrier films) |

| Film Cost | Low (Roll stock) | Low (Roll stock) | High (Premade bags) |

| Changeover Time | Medium | Fast | Fast |

5 Essential Features to Look for in a 2026 Model

When evaluating specifications from manufacturers, ensure these technologies are included:

- Servo Motor Drive (Multi-Axis): Avoid mechanical cam-driven machines. Servo motors (3-axis or more) offer precise control over film pull, product feeding, and cutting, allowing for instant size changes via touchscreen.

- No-Product-No-Packaging: Sensors detect if a biscuit is missing from the conveyor slot. The machine pauses the film and cutter, preventing empty bags and wasted film.

- Misplaced Product Detection: If a biscuit is slightly out of position (risking being cut by the jaw), the machine stops or rejects the item, preventing the knife from crushing the product and contaminating the seal.

- Sanitary Washdown Design: Look for stainless steel (SUS304) construction and cantilevered frames that allow crumbs to fall to the floor rather than getting trapped in the drive mechanisms.

- Remote Diagnostics: IoT-enabled PLCs allow technicians to troubleshoot your machine remotely, minimizing downtime.

Selecting the Right Packaging Materials for Freshness

The choice of material plays a key role in protection, shelf appeal, and cost-efficiency. Common materials include:

1. BOPP/CPP Films

- Widely used for pillow packs and flow wrap packaging.

- High clarity, heat-sealable, and cost-effective.

2. PET/PE or PET/AL/PE Laminates

- Multi-layer laminates offer superior barrier against moisture, light, and air.

- Ideal for biscuits with added flavors or fillings.

3. Premade Pouches

- Stand-up or gusseted pouches are increasingly popular in premium segments.

- Support vibrant printing and consumer convenience.

Biscuit Packaging Process: Step-by-Step

A typical biscuit packaging process includes:

1. Feeding and Alignment

- Biscuits are fed via conveyor belts.

- Optional sensors align them properly for wrapping.

2. Counting or Weighing

- Multi-head weighers or counting devices ensure consistent quantity per pack.

3. Film Forming and Filling

- In form-fill-seal machines, the packaging film is formed into a pouch or flow wrap around the biscuits.

4. Sealing and Gas Flushing

- Heat sealing ensures airtight closure.

- Nitrogen flushing is added for freshness (optional).

5. Date Coding and Labeling

- Inkjet or thermal printers add batch info, expiry date, etc.

6. Secondary Packaging

- Wrapped biscuits are packed into cartons or trays for shipping.

Conclusion: Protect Your Production Line

In the biscuit product, the packaging machine is the quality keeper of your brand. A low quality machine can save you money initially, but the costs associated with downtime, high breakage rates and leaking seals will eat away your profits over time.

Whether for the high-speed efficiency of a Horizontal Flow Wrapper for school snacks, or the premium presentation of a Rotary Pouch Machine for gourmet cookies, the goal is the same: Efficiency, Integrity, and Appeal. We are experts in the biscuit dough and packaging physics at Soontrue. We don’t just sell equipment, we design solutions for your specific shop space and production needs.

Ready to upgrade your bakery line? Don’t let outdated equipment eat away at your profits.

Contact Soontrue Today to discuss a consultation on custom biscuit packaging lines for the 2026 market.

Frequently Asked Questions (FAQ)

Q1: How do I prevent biscuits from breaking during the packaging process?

A: Use a Horizontal Flow Wrapper with a gentle, servo-driven belt feeding system rather than pusher chains. For extremely fragile items (like wafers), packing them in a plastic tray first provides necessary structural support.

Q2: What is the difference between "Fin Seal" and "Lap Seal"?

A: A Fin Seal joins the inside edges of the film together (like a fish fin), providing a stronger seal for gas flushing. A Lap Seal overlaps the film (inner to outer), using less film but offering a lower barrier. Fin seal is recommended for biscuits requiring long shelf life.

Q3: Can Soontrue Packing machines handle different pack sizes?

A: Yes. Our servo-driven machines allow you to save multiple "Recipes" in the HMI (touchscreen). You can switch from a 2-pack to a 10-pack configuration in minutes by selecting the preset, with the machine automatically adjusting bag length.

Q4: Is nitrogen flushing worth the extra cost?

A: If your supply chain exceeds 3 months or your product has high fat/oil content, yes. Nitrogen flushing displaces oxygen, preventing oxidation (stale taste) and cushioning the product against physical damage.

Q5: What is the lead time for a custom biscuit packaging line?

A: Standard standalone machines can be ready in 1-2 weeks. Complex fully automated lines with cooling tunnel integration and automatic feeding systems typically require 12-16 weeks for engineering and testing.