Packaging Machine Classification & Types: A Comprehensive Industrial Guide

Packaging Knowledge Hub

If you're seeking packaging automation solutions, please contact us, and we'll be delighted to offer you the most tailored solution.

Editor's Note (January 2026 Update):

This comprehensive guide has been revised to align with 2026 industrial manufacturing standards. We have updated our classification framework to reflect the latest shifts in automation logic, sustainable material compatibility, and the newest types of packaging machinery available in the global market.

1. Introduction

Packaging machines form the structural backbone of global manufacturing, silently enabling the movement of goods through the world's supply chains and ensuring that products in supermarkets, pharmacies, and industrial markets arrive safely, hygienically, and attractively. Although consumers rarely think about the machinery that places their biscuits into pillow bags or their coffee into stand-up pouches, packaging equipment lies at the center of production efficiency, hygiene compliance, and brand consistency. Understanding how packaging machines are classified, why different structures exist, and how various industries apply these machines is critical for professionals across engineering, procurement, production management, automation planning, and investment analysis. The classification of packaging machinery is not simply a matter of sorting machines into categories; it is a reflection of how different products behave, how industries operate, what packaging materials require, and what markets expect. This article presents a deeply integrated, narrative-style overview of packaging machine classification and applications, offering a unified framework that aligns with modern industrial needs and helps readers understand both the complexity and elegance of packaging automation.

2. Types of Packaging Machines by Structure (Structural Classification)

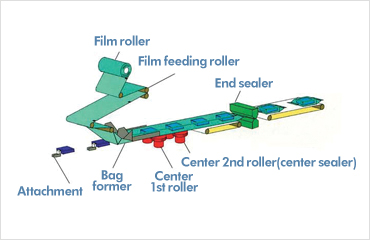

Packaging machines are most fundamentally understood through their structural design—how they feed products, form materials, apply seals, and synchronize movements. Structural classification is the backbone of the entire packaging machinery universe because almost every machine used in modern factories can be traced back to one of these core mechanical architectures. A horizontal flow wrapper, for example, has a completely different engineering philosophy from a vertical form-fill-seal (VFFS) system, not only in the directions of product and film flow but also in the rhythm of sealing, the geometry of product handling, and the nature of its optimal applications. When we study packaging equipment structurally, we begin with the machines that rely on hffs packaging flow. Flow wrappers, also known as pillow packing machines, are characterized by horizontal product feeding, continuous film wrapping, longitudinal sealing on the underside, and end-sealing formed by rotating or reciprocating jaws. These machines are indispensable in industries that demand speed, such as baked goods, confectionery, and consumer goods. Their ability to deliver consistent seal quality at very high speeds—sometimes exceeding 400 to 1,000 packs per minute—has made them a global standard for single-serve packaged items. The engineering behind flow wrappers is elegant: a conveyor positions products precisely while servo motors coordinate film pulling and jaw movement to ensure every package is sealed with symmetrical pressure and temperature control. The result is a visually appealing, commercially ready pillow bag that balances efficiency with marketing aesthetics.

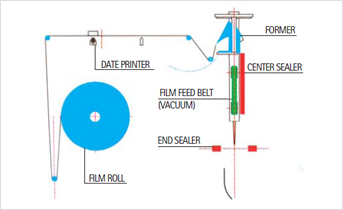

The next major structural category is the vertical form-fill-seal machine, or VFFS, which dominates the packaging of powders, granules, liquids, pastes, and frozen items. Unlike flow wrappers that handle pre-arranged products horizontally, VFFS relies on gravity as a natural ally. Film unwinds downward, wraps around a forming tube to create a vertical bag, and the product enters from above, enabling seamless alignment between filling and sealing. VFFS is exceptionally versatile because it can integrate a range of dosing systems—volumetric cups for consistent granule measurement, combination weighers for high-accuracy snack filling, auger fillers for powders, piston pumps for liquids, and peristaltic pumps for viscous products. The flexibility of VFFS machines enables manufacturers to shift between bag styles such as pillow bags, gusseted bags, quad-seal bags, or stick packs depending on market demand. The architecture is modular, easily scalable, and well suited for industries from snacks and frozen foods to chemicals and pharmaceuticals.

In contrast, premade pouch packing machines represent a different structural philosophy—one that prioritizes premium aesthetics and flexible packaging formats. Instead of forming bags from roll film, premade pouch machines handle pre-formed bags such as stand-up pouches, flat-bottom bags, zipper bags, and spout pouches. These machines typically use rotary or linear stations to pick, open, fill, and seal bags in a controlled mechanical sequence. Brands in the coffee, pet food, detergent, and high-value snack categories often adopt premade pouches to elevate their shelf presence and differentiate themselves in competitive markets. Although premade pouches cost more than roll film on a per-unit basis, the marketing advantages—enhanced print quality, convenience features like zippers, and high perceived value—justify the investment for premium product lines.

Shrink wrapping machines, another structurally unique category, serve a different purpose by creating tight, secure, multi-unit bundles using heat-shrinkable film. These machines are essential for beverage packs, household product multipacks, and industrial products requiring bundling strength for transport. Their operation relies on film sealing followed by heat exposure that shrinks the film uniformly around the product. This structural principle is highly efficient for warehouse logistics and reduces carton usage.

Finally, secondary and tertiary packaging machines such as cartoners, case packers, and palletizers complete the structural classification system. Cartoning machines automatically form cartons, insert products, and close boxes. Case packers group and load primary packages into larger cases. Palletizers arrange these cases onto pallets in stable patterns ready for storage or shipment. These systems represent the end-of-line (EOL) stage of packaging and are essential for full-scale automation. Together, the structural classification of packaging machines provides the industry's architectural blueprint—one that engineers and production managers rely on when designing packaging lines or optimizing factory workflows.

Quick Comparison: Structural Types of Packaging Machines

| Machine Type | Best For (Product Form) | Speed & Efficiency | Key Advantages | Primary Industries |

| Flow Wrapper (HFFS) | Solid, single items (biscuits, soap, bread) | High Speed (400–1,000+ packs/min) | Symmetrical sealing, continuous motion, gentle handling. | Bakery, Confectionery, Consumer Goods |

| VFFS Machine | Granules, powders, liquids, frozen items | High versatility & fast changeover | Uses gravity for filling; supports various bag styles (pillow, gusseted). | Snacks, Frozen Food, Chemicals, Pharma |

| Premade Pouch Machine | Premium items requiring zippers or spouts | Moderate speed, High Quality | Superior shelf appeal, handles complex bag shapes (stand-up, flat-bottom). | Coffee, Pet Food, Detergent, Nuts |

| Cartoning Machine | Secondary packaging (pouches, blisters) | Synchronized with primary lines | Automates box forming and loading; ensures structural protection. | All Sectors (End-of-Line Automation) |

3. Classification by Industry and How Packaging Machines Adapt to Sector-Specific Requirements

While structural classification provides the mechanical foundation, industry classification reveals how different sectors impose unique constraints and expectations on packaging machines. The food industry, for example, requires machinery that prioritizes hygiene, speed, and freshness preservation. Snack manufacturers rely heavily on VFFS machines paired with multi-head weighers to achieve fast, precise filling. Biscuit factories use flow wrappers equipped with intelligent infeed systems that prevent breakage. Frozen food manufacturers need equipment that withstands cold, humid environments and manages irregular-shaped items like dumplings or vegetables. Every food segment imposes its own challenges—oil content in nuts affects seal integrity; fragility in chips demands gentle feeding; freshness in bread requires modified atmosphere options. Packaging machines must respond with intelligent control systems, specialized sealing jaws, or tailored material compatibility.

Pharmaceutical packaging represents an even more demanding category, defined not by marketing aesthetics but by stringent regulatory standards such as GMP, FDA, and ISO. Pharmaceutical products require tamper-evident seals, batch traceability, highly accurate dosing, sterile conditions, and serialization capabilities. Machines must maintain precision at all times because even minor deviations can compromise dosage integrity or sterility. Flow wrappers used for medical devices require aseptic-friendly designs and reject systems to ensure no product exits the line without meeting tolerance. Sachet machines used for powders and granules must provide exact dosing and contamination control. Cartoning systems must handle leaflets, tamper closures, and coding systems with flawless reliability.

In the daily chemical and personal care industries, machines must adapt to liquids with varying viscosities, products that foam easily, and packages that must remain visually appealing despite handling aggressive detergents or fragrances. Stand-up pouches with zippers and spouts are increasingly popular here, requiring sophisticated pouch handling and sealing technologies that can maintain integrity even with complex laminate materials.

Industrial and chemical products introduce another layer of classification. Fertilizers, cement additives, and industrial powders require heavy-duty VFFS systems equipped with dust control. Lubricants and thick chemicals require positive-displacement pump fillers and reinforced sealing systems. Some industrial components require shrink-wrapping or flow-wrapping for protection during transport. The needs vary widely, but each application places unique demands on the machinery’s structure, environment resistance, durability, and integration capability.

Through industry classification, we discover the diversity of real-world requirements. Packaging machines do not simply package “products”—they package entire industry ecosystems with expectations shaped by global standards, consumer preferences, regulatory frameworks, and supply chain realities.

4. Classification by Product Form and How Physical Properties Influence Machine Selection

The physical form of a product fundamentally shapes the packaging machine needed. Solid products such as biscuits, hardware tools, or soap bars require machines that organize items into consistent orientation and spacing before wrapping. Flow wrappers handle these efficiently because their horizontal feeding system aligns items in a linear arrangement. When products are fragile, such as cookies or pastries, machines must incorporate gentle feeding belts, low-contact mechanisms, or robotic aligners to prevent breakage.

Granular products—including rice, beans, nuts, pet food, and seeds—flow easily under gravity, making them ideal candidates for VFFS machines equipped with volumetric cup fillers or multi-head weighers. Granules vary in density, shape, and fluidity, which influences filling accuracy and film selection. Multi-head weighers are especially effective because they combine multiple weight cells to achieve nearly perfect dosing accuracy.

Powders behave differently from granules. Fine powders such as coffee, spices, milk powder, or pharmaceutical ingredients require auger fillers because augers can control flow properties irrespective of clumping or density changes. Powder packaging must consider dust management, sealing integrity, and contamination risks, especially in spices or pharmaceuticals. Bag types for powders often emphasize barrier protection and sealing strength.

Liquids and pastes—including sauces, juices, oils, gels, shampoos, and detergents—require machinery capable of maintaining precise volumetric control while preventing leaks. These products typically use VFFS systems combined with piston pumps or peristaltic pumps. Premade pouch machines with spout sealing systems are popular in premium liquid packaging because they offer excellent shelf appeal and user convenience.

Irregular products, such as dumplings, frozen vegetables, hardware pieces, or shaped confectionery, pose unique handling challenges. They require wide forming tubes, customized feeding systems, or adaptive flow-wrapping approaches to ensure each item is properly positioned for packaging. This classification demonstrates that no matter how advanced the machinery is, it ultimately must adapt to the physical behavior of the product.

5. Classification by Bag Types and How Packaging Formats Shape Machine Requirements

Bag type classification focuses on the packaging format used by consumers and retailers. Pillow bags, the simplest and most widely used, offer economy, speed, and practicality. They are suited for snacks, biscuits, noodles, and countless other products. Gusseted bags add side-volume capacity, enabling bulkier products or larger quantities. Stand-up pouches dominate premium markets because they display well on shelves and accommodate zippers, spouts, or vent features. Zipper bags enhance consumer convenience and reusability. Quad-seal and flat-bottom bags offer box-like appearance—ideal for coffee, pet food, and specialty items. Smaller sachets, in three-side or four-side seal formats, are well suited for single-serve spices, instant beverage powders, or medical applications. The machine selection depends heavily on the bag format because each design demands different sealing positions, film handling, and mechanical coordination.

6. Packaging Applications: Pain Points, Machine Logic, and End-to-End Packaging Flows

Real industrial packaging cannot be understood without considering full workflows. In baked goods, products are fragile, irregular in batches, and require synchronized feeding. A bakery flow line may begin with conveyors that cool products, proceed through aligners that stabilize positions, and then feed into high-speed flow wrappers. Downstream, checkweighers, metal detectors, and cartoners complete the process before palletizing.

In snack manufacturing, nitrogen flushing is essential to maintain crispness and prevent oxidation. Products enter combination weighers that deliver highly accurate dosing to VFFS machines, which form nitrogen-filled pillow bags that maintain freshness. Processed bags then undergo checkweighing and secondary packaging.

Frozen food workflows differ significantly. Dumplings or vegetables require anti-stick systems, low-temperature compatibility, and wide forming tubes. Packaging materials must be selected for anti-fog properties. Flow wrappers or VFFS machines may be followed by shrink wrapping for bulk logistics.

Pharmaceutical workflows emphasize sterility and traceability. Sachet packaging must remain particle-free; flow wrappers for medical devices must reject any deviation; cartoners integrate serialization, leaflet insertion, and tamper-evident closure.

Each of these application scenarios illustrates the real-world logic behind packaging machinery selection. Machines are never chosen based on structural category alone—they are selected based on application pain points, product physics, regulatory constraints, and desired workflow efficiency.

7. Conclusion

Packaging machines form a complex, interconnected ecosystem in modern manufacturing. Through structural, industry-based, product-form, and bag-type classification, we gain a comprehensive understanding of how and why specific machines exist. These classification methods reveal the engineering logic behind packaging systems and provide a roadmap for selecting the right machinery for any industrial scenario—from snacks and baked goods to pharmaceuticals, chemicals, and daily-use products. Ultimately, packaging machinery is not simply an equipment category; it is a strategic enabler of quality, efficiency, hygiene, branding, and supply chain readiness in every factory that produces physical goods.

8. FAQ

Q1: What are the main categories of packaging machines?

Packaging machines are commonly classified by structure (flow wrapper, VFFS, premade pouch machine, shrink wrapper, cartoner), by industry (food, pharma, chemical), by product form (solid, powder, liquid, paste), and by packaging format such as pillow bags, stand-up pouches, or zipper bags.

Q2: How do I choose the right packaging machine for my product?

Selection depends on product form, required packaging format, hygiene standards, production speed, filling accuracy, and industry-specific requirements. Solid items often use flow wrappers, powders use VFFS with auger fillers, liquids require pump-based systems, and premium products fit premade pouch machines.

Q3: Which packaging machines are most commonly used in the food industry?

Flow wrappers are used for biscuits and bakery goods, VFFS machines for snacks and frozen foods, premade pouch machines for premium nuts and coffee, and shrink wrappers for beverage multipacks. Food factories typically combine these with checkweighers, metal detectors, and cartoning systems.

Q4: How does product form affect packaging machine choice?

Granules flow well and work best with VFFS plus volumetric or multi-head weighers. Powders require auger fillers to control dust and maintain accuracy. Liquids and pastes need pump systems and leak-proof sealing. Irregular items such as dumplings require wide films and customized feeding.

Q5: Which industries require the highest packaging precision?

Pharmaceutical, medical device, and nutraceutical industries require strict accuracy, traceability, batch coding, and tamper-evident sealing. These sectors often rely on sachet machines, flow wrappers for sterile devices, and automated cartoning systems with serialization.

Q6: What is the role of packaging machines in end-of-line automation?

Packaging machines integrate with cartoners, case packers, palletizers, and inspection systems to create fully automated packaging lines. These systems increase efficiency, reduce labor, and ensure uniformity across large-scale industrial production.

Q7: Can one packaging machine handle multiple product types?

Some machines offer multi-product versatility, especially VFFS and premade pouch systems with changeover features. However, optimal performance usually requires matching machine structure to product characteristics to maintain speed, accuracy, and seal quality.

Q8: Why are premade pouch machines popular in premium categories?

Premade pouch machines produce high-value packaging formats—stand-up pouches, zipper bags, flat-bottom bags—that offer superior shelf appeal, reusability, and branding potential. They are ideal for coffee, pet food, nuts, and specialty products.

Q9: What is the most versatile packaging machine structure?

VFFS machines are considered the most versatile because they support many fillers (weigher, auger, pump), handle multiple bag styles, and work with powders, granules, liquids, and frozen items. They are widely used in food, chemical, and pharmaceutical sectors.

9.Related Knowledge Articles

- Horizontal Flow Wrapping Machines: Structure & Typical Applications

- Vertical Form-Fill-Seal (VFFS) Packaging Machines: Structure & Applications

- Premade Pouch Packing Machines: How They Work & When to Use Them

- Wrapping Machines & Overwrapping: Secondary Packaging for Presentation

- Cartoning Machines: From Individual Packs to Retail-Ready Cartons

- Case Erectors & Case Sealers: Forming and Closing Shipping Cases

- Case Packers & Wrap-Around Packers: Building Transport-Ready Units

- Palletizing Systems & End-of-Line Automation

- Supporting Equipment: Feeding, Weighing, Inspecting & Printing