Carton Overwrapping & Box Wrapping Machines for Secondary Packaging

Packaging Knowledge Hub

If you're seeking packaging automation solutions, please contact us, and we'll be delighted to offer you the most tailored solution.

This article is part of the Soontrue Packaging Knowledge Series under the "Packaging Machine Classification & Applications" section. For a broader overview of packaging layers and machine types, see Packaging Machine Classification & Applications and Primary, Secondary & Tertiary Packaging Explained.

When a product has already been packed in a primary bag, tray or carton, manufacturers often add one more layer to improve appearance, tamper evidence and protection. This is the role of the wrapping machine or overwrapping machine. Instead of forming a pillow bag around loose product, a box wrapping machine or film overwrapping machine wraps a tight layer of film around individual cartons or multipacks, creating a clean, rectangular pack that looks premium on the shelf and survives transport better.

For brands selling cosmetics, tea, confectionery, pharmaceuticals, electronics, cigarettes or gift items, overwrapping machines are a key part of the secondary packaging strategy. This article explains what wrapping and overwrapping machines are, how they work, where they are used, and when they are the right choice compared with flow wrapping or shrink bundling.

1. What Is a Wrapping / Overwrapping Machine in Packaging?

A wrapping machine in this context is a piece of secondary packaging equipment that wraps a piece of film—commonly BOPP or cellophane-type—around a product that already has its primary package, usually a carton, rigid tray or stacked bundle. The film is folded tightly around the pack and sealed, often creating neat "cigarette-style" folded corners.

When people talk about an overwrapping machine, they usually mean a film overwrapping machine for cartons and boxes, not a shrink wrapper for loose bundles. The overwrap:

- protects the underlying carton from dust, moisture and scuffing

- adds tamper evidence (the overwrap must be broken to open the product)

- creates a glossy, premium appearance with crisp edges

- allows the use of tear tape for easy opening

Typical examples include a box of chocolates wrapped in clear film, a perfume carton with tear tape, or a box of tea bags wrapped like a cigarette pack. In each case, the primary packaging (inner bag, tray or sachet) protects the product itself, while the secondary overwrap enhances presentation and handling.

Unlike a horizontal flow wrapper, which forms a tube around loose or semi-loose products and produces a pillow-type pack, a box wrapping machine works with regular, usually rectangular items that need a tight, shape-following wrap.

2. How Overwrapping Machines Work and Main Machine Types

Although designs vary, most overwrapping machines follow the same basic principle: they cut a sheet of film, position it relative to the product, fold it around the product using mechanical folders, and seal the film at overlapping areas.

2.1 Basic working principle

A typical carton overwrapping machine performs the following steps:

- Product infeed – individual cartons or bundles are fed into the infeed, usually in a single line. An aligning device ensures correct spacing and orientation.

- Film feeding and cutting – flat BOPP or cellophane film is pulled from a roll and cut into sheets of predetermined length. The sheet length is matched to the carton dimensions and required overlap.

- Film positioning – the cut sheet is placed underneath or above the carton, depending on machine design, ready to be folded.

- Folding and tucking – mechanical folders and plates wrap the film around the four sides of the carton. The ends are tucked and folded to form the classic "envelope" or "cigarette pack" style corner.

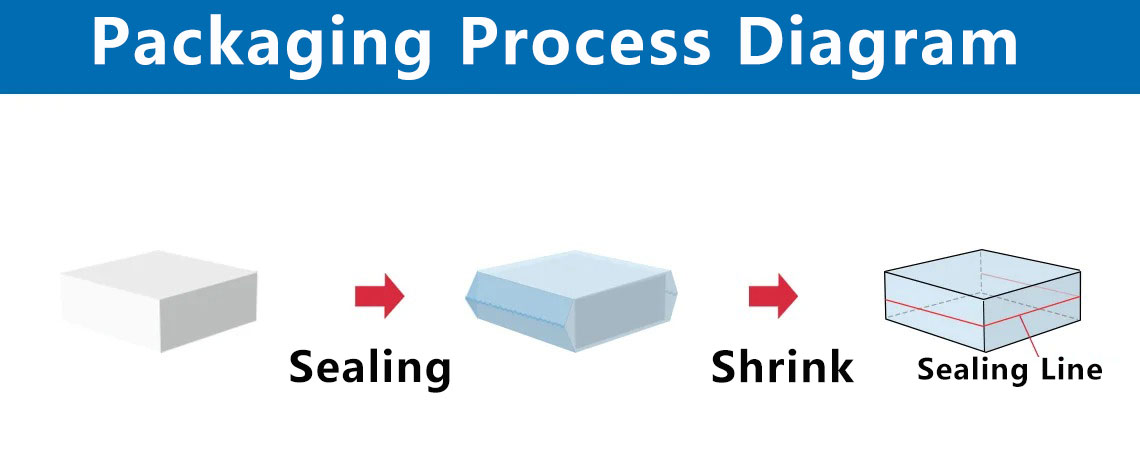

- Sealing – heated plates or sealing elements apply heat and pressure on the overlapping film edges to create nearly invisible seals. For some films, only a small contact area is needed; other materials may require broader seal zones.

- Discharge – the wrapped and sealed carton is discharged to a conveyor, ready for case packing or direct cartoning for retail.

Because the product is already rigid and dimensionally stable, the machine can create extremely sharp corners and a tight wrap, something that is difficult to achieve with shrink film alone.

2.2 Common types of wrapping and overwrapping machines

In the wrapping machine category you will usually see several sub-types:

- Carton overwrapping machine / box wrapping machine – for single cartons such as tea, perfume, cosmetics, chocolate or pharma boxes.

- Bundle overwrapping machine – for creating multipacks, for example 3 or 4 cartons wrapped together as a promotional or wholesale unit.

- High-speed film overwrapping machine – continuous or indexing systems designed for cigarette-style packs, capable of very high throughput.

- Shrink wrapping machine (bundle wrapper) – although technically different, shrink wrappers are often grouped together as "wrapping machines". They wrap film loosely around a bundle and use a shrink tunnel to tighten it, rather than folding and tucking like an overwrap.

For the purposes of this knowledge series we focus mainly on film overwrapping machines for cartons, as they are closely related to cartoning and other secondary packaging equipment in automated lines.Not sure which overwrapper fits your product? Contact our engineers for a free packaging solution consultation.

3. Typical Applications and Packaging Formats for Wrapping Machines

Because they handle already-packed products, wrapping and overwrapping machines appear in many industries where visual presentation and tamper evidence are important.

3.1 Confectionery, tea and premium food

In confectionery and specialty food, overwrapping is common for:

- boxed chocolates and pralines

- gift boxes of biscuits or cookies

- tea cartons containing multiple envelopes or tea bags

- premium coffee or specialty food cartons

Here, an overwrapping machine gives the carton a luxurious finish, with a glossy surface and sharp edges. The overwrap keeps cartons clean in transport and storage and can carry tear tape that makes unboxing more satisfying for the consumer.

3.2 Cosmetics, perfume and personal care

For cosmetics and fragrance brands, a box wrapping machine is almost mandatory at the high end. Typical applications include:

- Perfume Carton Overwrapper

- skincare and cosmetic sets

- high-end personal care gift boxes

In this segment, the overwrap is part of the brand language: a perfectly wrapped box signals premium quality and protection, and the tamper-evident film reassures consumers that the product has not been opened before purchase.

3.3 Pharmaceuticals and healthcare

In pharmaceuticals, overwrapping machines are often used in combination with cartoning machines to wrap:

- medicine cartons

- OTC product cartons

- small medical device packs

Overwrap adds a second layer of tamper evidence and protects printing and barcodes on the carton from abrasion. For some markets, regulatory guidelines or brand policies require this extra layer of security.

3.4 Multipacks and promotional bundles

Wrapping machines are also used to create multipacks—several primary packs grouped together. For example:

- 3-pack promotions of toothpaste cartons

- 2-for-1 chocolate boxes

- multi-carton bundles for wholesale clubs

Depending on the design, these can be overwrapped with neat folds or shrink-wrapped as bundles. In both cases, the underlying goal is to improve handling and create a distinct visual unit for retail or logistics.

3.5 Tray Overwrapping for Food & Beverage

While most overwrapping applications focus on standalone cartons, tray overwrapping is a critical solution for the food and beverage sectors. In this format, products (such as beverage cartons, yogurt cups, or canned goods) are placed in a cardboard tray before being wrapped.

This method is distinct from shrink wrapping. A tray over wrapping machine uses the fold-and-tuck method to create a tight, crystal-clear seal around the tray without using heat tunnels that might damage sensitive products like chocolate or dairy.

Key applications include:

- Beverage Multipacks: Grouping 3 or 6 units of juice boxes or milk cartons (brick packs) onto a shallow tray.

- Shelf-Ready Display Trays: Confectionery or snack bars placed in open display trays, wrapped for transit but ready for immediate shelf placement after film removal.

This approach is ideal for tray overwrapping in beverage and food industries, offering a more premium, sustainable alternative to bulky shrink film while ensuring product stability and hygiene.

4. Where Wrapping & Overwrapping Fit in the Packaging Line

From the perspective of line design, wrapping machines are part of the secondary packaging and end-of-line area. They rarely stand alone; instead they are integrated with upstream and downstream equipment.

A typical flow might look like this:

- Primary packaging – flow wrapper, vertical packaging machine, blister packer, bottle filler, etc.

- Cartoning – individual units packed into cartons by a cartoning machine.

- Overwrapping – cartons pass through an overwrapping machine for film wrapping and tear tape application.

- Case packing – wrapped cartons are grouped and loaded into shipping cases by a case packer or wrap-around packer.

- Palletizing – cases are stacked onto pallets by a palletizing robot or conventional palletizer.

In some lines, a bundle wrapping machine replaces individual overwrap when the goal is purely logistics (for example, shrink-wrapped tray packs for beverages). In other lines, especially cosmetic and high-end food, the overwrapping machine is non-negotiable because it directly affects perceived product value.

When planning automation, manufacturers must decide:

- whether only premium SKUs go through overwrapping,

- what speed the wrapping machine must match relative to the cartoner,

- and how wrapped and unwrapped products are diverted or merged before case packing.

Choosing flexible wrapping and overwrapping equipment with servo control, recipe-based changeover and easy access for film threading and maintenance helps keep this part of the line efficient and reliable.

FAQ

Q1: What is the difference between a flow wrapper and an overwrapping machine?

A flow wrapper (pillow packing machine) forms a pillow bag around loose or semi-loose product, creating the primary pack. An overwrapping machine wraps film around a finished carton or bundle as secondary packaging, mainly for appearance and tamper evidence.

Q2: Is overwrapping the same as shrink wrapping?

No. An overwrapping machine folds and tucks flat film tightly around a box, creating sharp corners and often using tear tape. A shrink wrapping machine wraps film loosely and then uses heat to shrink it around the bundle.

Q3: When should I consider adding a wrapping machine to my line?

You should consider a wrapping machine when you need a more premium look, added tamper evidence, cleaner cartons in distribution, or when you want to create multipacks from several primary packs.

Q4: Can the same overwrapping machine handle different carton sizes?

Yes. Most modern box wrapping machines are designed for multiple carton sizes within a defined range, with change parts and recipe settings that reduce format changeover time.

Q5: How does overwrapping affect sustainability?

Overwrapping adds an extra film layer, but it can also reduce product damage and returns. Some brands are moving toward thinner, recyclable BOPP films and optimizing carton designs to balance appearance, protection and material usage.

Related Knowledge Articles

How wrapping and overwrapping machines fit alongside flow wrappers, VFFS, cartoners and case packers in the overall classification.

Upstream equipment that usually feeds cartons into overwrapping machines.

Primary packaging of bars, bakery products and other items before cartoning and overwrapping.

How wrapped cartons are grouped into shipping cases and integrated into palletizing systems.

A detailed explanation of packaging layers and where overwrapping fits.

Considerations when overwrapping food or pharma cartons that require clean, controlled environments.