Case Erecting & Case Sealing Machines: Forming and Closing Shipping Cartons

Packaging Knowledge Hub

If you're seeking packaging automation solutions, please contact us, and we'll be delighted to offer you the most tailored solution.

This article is part of the Soontrue Packaging Knowledge Series under the "Packaging Machine Classification & Applications" section. For a broader view of packaging layers and machine types, see Packaging Machine Classification & Applications and Primary, Secondary & Tertiary Packaging Explained.

In an automated packaging line, once products have been wrapped, bagged, pouched or cartoned, they still need to be placed into shipping cases for transport and distribution. This is where case erecting machines and case sealing machines play a crucial role. Together, they form and close corrugated cartons so that they are ready for palletizing and outbound logistics.

A case erector—also called a case erecting machine, case forming machine or carton erecting machine—automatically takes flat corrugated blanks, opens them into a box shape and seals the bottom flaps. A case sealer—also known as a case sealing machine, carton sealer or case taping machine—closes and seals the top flaps of filled cases with tape or hot-melt glue. These two types of equipment form the backbone of modern end-of-line packaging.

This article explains what case erectors and case sealers are, how they work, the main machine types (including horizontal case erectors, vertical case erectors, mechanical-arm and servo designs), typical applications, and how they fit into complete case packing and palletizing systems.

1. What Are Case Erectors and Case Sealers, and How Do They Work?

A case erector is a machine that automatically converts flat corrugated case blanks into fully formed cases with a sealed bottom, ready for product loading. Instead of operators manually opening each blank and taping the bottom, the case erecting machine performs this task with consistent speed and quality.

A case sealing machine performs the complementary step at the end of the case packing process: it closes the top flaps of filled cases and applies tape or glue, producing a finished, stable shipping carton.

1.1 Basic working principle of a case erector

Although designs differ, a typical case erector works in the following sequence:

- Blank feeding

Flat case blanks are stacked in a magazine. A vacuum arm or mechanical suction system picks one blank at a time.

- Case opening

The blank is pulled or pushed into an open, rectangular shape. Depending on the design, this is done with mechanical arms, cams and linkages, or with servo-driven motion systems that control the opening precisely.

- Bottom flap folding

The bottom flaps are folded in a defined sequence—usually leading flap, trailing flap and then inner and outer flaps—so that the case remains square.

- Bottom sealing

The bottom of the case is sealed either with adhesive tape or hot-melt glue.

- In a tape-type case erector, side belts drive the case through a bottom taping head, which applies tape across the bottom seam.

- In a hot-melt case erector, a glue unit applies hot-melt glue to the bottom flaps and compression devices press the flaps together until the bond is set.

Both sealing methods can be used for bottom sealing; the choice depends on product weight, logistics conditions and company packaging standards.

- Discharge

The erected and bottom-sealed case is discharged onto a conveyor, ready to be loaded manually or automatically by a case packer.

1.2 Basic working principle of a case sealer

A case sealer typically processes cases that have already been filled with products:

- Case infeed and flap folding

Filled cases enter the machine on a conveyor. Mechanical guides and folding bars fold the side and top flaps into the correct position.

- Top sealing

A taping or gluing head applies adhesive tape or hot-melt glue across the top seam, creating a strong, consistent seal.

- Discharge

The sealed case exits the case sealing machine and moves towards labeling, checkweighing or palletizing.

Both case erecting and sealing steps are critical to ensure that cartons remain square, stable and secure throughout handling, storage and shipping. Poorly formed or poorly sealed cases can lead to product damage, pallet instability and safety issues.

2. Types of Case Erectors and Case Sealers

There are multiple ways to classify case erecting and case sealing machines. For practical selection, four dimensions are especially useful: case orientation (horizontal vs vertical), motion/drive type (mechanical vs servo), sealing method (tape vs hot-melt) and level of automation (semi-automatic vs fully automatic).

2.1 Horizontal vs Vertical Case Erectors

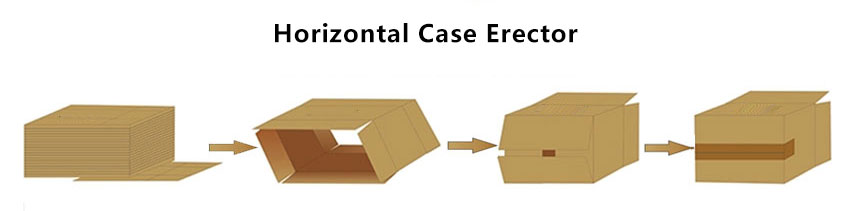

Besides drive type, case erecting machines can also be classified by how the case is oriented during forming. In real projects this usually means choosing between a horizontal case erector and a vertical case erector. While both can form standard RSC cartons, their stability and behavior in high-speed lines are not the same.

Horizontal case erector

In a horizontal case erector, flat blanks are stored horizontally in a magazine. A suction system picks a blank, pulls it out sideways and opens it into a rectangular shape while the case lies on its side. The bottom flaps are folded and sealed in this horizontal position, and the erected case is then transferred onto a conveyor.

Many traditional horizontal case erecting machines rely heavily on pneumatic cylinders for opening and forming motions. This makes overall stability more sensitive to the quality of the compressed air supply. If the air pressure fluctuates or the air is not clean and dry enough, mis-erects, partially opened cases or deformed corners can occur, especially at higher speeds.

Horizontal designs are common in older or simpler lines and can be a good fit where:

- line speeds are moderate

- the case size range is limited

- the plant already runs many pneumatic systems and has very stable air utilities

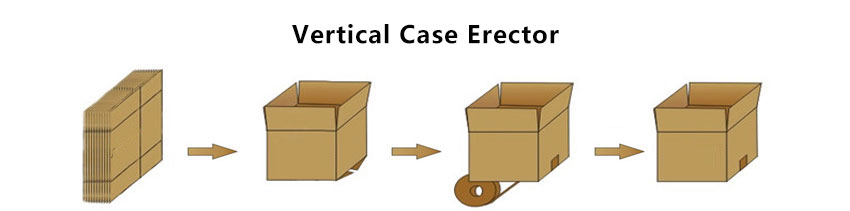

Vertical case erector

A vertical case erector keeps the case standing upright during forming. Blanks are picked from the magazine and opened so that the case stands on its bottom panel with the open top facing upward. The bottom flaps are folded and sealed while the case is in this vertical position, and the erected case is discharged standing up, ready for top-load or side-load case packing.

Because the case is supported by its bottom panel and gravity helps keep it square, a vertical case erecting machine typically offers:

- stronger structural stability during forming

- better squareness and more consistent case geometry

- less sensitivity to compressed-air fluctuations, especially when combined with servo-driven axes

- more reliable operation at higher speeds or under 24/7 production conditions

For these reasons, many modern automated lines now prefer vertical case erectors, particularly where case quality and line uptime are critical. Soontrue’s case erecting solutions are based on this vertical case erector concept, combining upright forming with servo-controlled motion to enhance stability, support a wider case-size range and simplify integration with automatic case packing and palletizing systems.

In practice, both horizontal case erectors and vertical case erectors can technically run standard corrugated cases. However, when manufacturers are looking for higher stability, better performance under varying air conditions and easier integration into fully automated lines, a vertical case erector is often the preferred option.

2.2 Standard servo case erector vs Robotic box erecting machine

From an architecture and control perspective, modern vertical case erectors in many factories are based on two main concepts:

- Standard servo vertical case erector

- Robotic box erecting machine

Both use servo technology, but the structure and performance level are different.

Standard servo vertical case erector

A standard servo case erector is built around a vertical forming structure where several key motions—blank picking, opening, transport and flap folding—are driven by servo motors and supported by pneumatic actuators. Motion profiles and timing are defined in the servo controller, allowing:

- recipe-based changeovers between different case sizes

- better control of case squareness compared with purely pneumatic or cam-driven designs

- reliable performance in medium to high-speed lines

This type of machine is a solid, cost-effective solution for many food, beverage and consumer-goods factories looking to automate case forming with a good balance of performance and investment.

Robotic box erecting machine

A Robotic box erecting machine (also called a Robotic case erector or Robotic box opener) takes the concept further. Instead of relying solely on fixed mechanical linkages, a robotic arm picks up the flat blank, opens the case and holds it in position while the bottom flaps are folded and sealed.

Compared with a standard servo case erector, a Robotic box erecting machine typically provides:

- higher flexibility in how blanks are picked, opened and supported

- smoother, more controlled opening motion, especially for larger or heavier blanks

- easier adaptation to different case designs and future packaging changes

- more advanced positioning possibilities when integrating with complex layouts or multiple downstream lines

In other words, both designs use servo control, but the Robotic box erecting machine is positioned as the higher-end solution above the standard servo vertical case erector, especially for customers who need maximum flexibility, smoother opening motion and more advanced integration with automatic case packing and robotic palletizing.

2.3 Tape vs hot-melt sealing for case bottoms and tops

From a sealing-method perspective, both case erectors (bottom sealing) and case sealing machines (top sealing) mainly use two methods:

- Adhesive tape (tape case sealers / tape-type case erectors)

- Simple and widely used

- Easy tape roll changes and relatively low operating cost

- Suitable for many applications where cases are not extremely heavy

- Hot-melt glue (hot-melt case sealers / hot-melt case erectors)

- Stronger, more rigid closure

- Often preferred for heavy or high-value products and long-distance shipping

- Requires a glue melter, hoses and nozzles and regular maintenance

In practice, factories may use tape for standard-weight cases and reserve hot-melt for heavier loads, export shipments or when extra rigidity is required for pallet stability. The key is to align the sealing method for both bottom and top with product weight, warehouse conditions and transport scenarios.

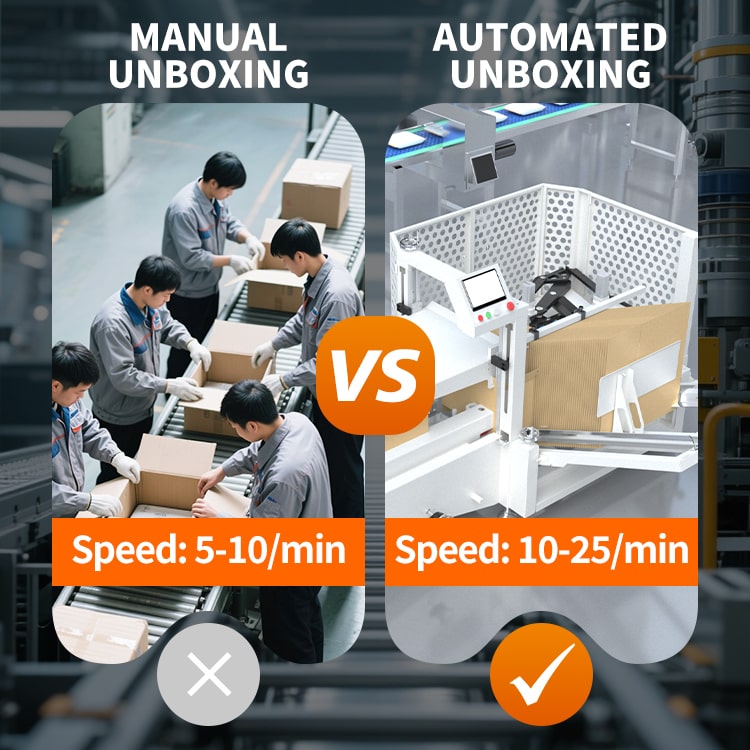

2.4 Semi-automatic vs fully automatic systems

In terms of automation level:

- Semi-automatic case erector / case sealer

- The machine assists with opening or sealing, but operators still perform some steps manually (for example, placing products into open cases or manually folding some flaps).

- A good entry-level option for smaller factories transitioning from fully manual operations.

- Fully automatic case erecting and sealing machines

- Open, form and seal cases with minimal operator intervention.

- Designed to feed directly into an automatic case packer and palletizing system, forming part of a continuous end-of-line solution.

As line speeds and labor costs increase, most medium to large factories migrate towards fully automatic case erecting and case sealing systems integrated into complete packaging lines.

3. Typical Applications and Line Configurations

Because they handle shipping cases, case erectors and case sealers appear in almost every industry that uses corrugated cartons.

3.1 Food, beverage and consumer goods

In food and beverage plants, typical applications include:

- erecting cases for flow-wrapped biscuits, bakery items or confectionery

- forming cases for bags of snacks, pasta, rice or frozen products

- sealing cases loaded with coffee packs, premade pouches or multipack cartons

- closing cases with bottled or canned drinks (often after tray packing or wrap-around packing)

Here, case erecting machines and case sealing machines are usually installed directly upstream and downstream of case packers or wrap-around case packers.

3.2 Household, personal care and cosmetics

For household and personal care products, case erecting and sealing support:

- shipping cartons of detergents, cleaning products and refills

- cases containing cosmetic cartons or overwrapped perfume boxes

- bulk cases for retail distribution and e-commerce fulfillment

In these industries, a neat, square case is important not only for pallet stability but also for warehouse automation systems such as automatic storage and retrieval or shuttle systems.

3.3 Pharmaceuticals, healthcare and industrial products

In pharmaceuticals and healthcare, case erecting and sealing machines are used to:

- form cases for serialized medicine cartons

- seal cases that hold medical devices or diagnostic kits

- integrate with aggregation and track-and-trace systems

For industrial goods, hardware, electronics or B2B kits, case erecting and case sealing ensure that heavy or sensitive products arrive at the customer in good condition, with consistent labeling and barcodes.

3.4 Typical line configurations

Depending on plant size and automation goals, you might see:

- Simple configuration

- Manual case loading

- Semi-automatic case erector

- Semi-automatic case sealer

- Intermediate configuration

- Automatic case erector

- Manual or semi-automatic case packing

- Automatic case sealing machine

- Fully automatic configuration

- Case erector → automatic case packer → case sealer → palletizer

The more automated the line, the more important it becomes to ensure that case erecting machines produce square, consistent cases and that case sealing machines can keep up with case packing speed.

4. How Case Erecting and Sealing Fit into End-of-Line Automation

In an integrated end-of-line packaging system, case erectors and case sealers are essential building blocks. They frame the case packing process—one at the beginning, one at the end.

A typical end-of-line setup might look like this:

Products are packed by flow wrappers, vertical packaging machines (VFFS), premade pouch packing machines, cartoners or overwrapping machines.

- Case forming

A case erecting machine automatically forms and bottom-seals shipping cases from flat blanks. Cases are discharged in a consistent orientation onto an infeed conveyor.

- Case packing

Products are loaded into open cases by an automatic case packer—either pick-and-place, side-load or top-load design. Layer patterns and counts are defined by recipes.

- Case sealing

Filled cases move into a case sealing machine where the top flaps are folded and sealed with tape or glue.

- Palletizing and stretch wrapping

Sealed cases are conveyed to a palletizing robot or conventional palletizer and then wrapped for storage and shipping.

When planning an automated line, manufacturers should consider:

- required case size range and changeover frequency

- integration of case erectors and case sealers with case packers and palletizers

- choice between horizontal case erector and vertical case erector based on layout and stability needs

- choice between mechanical/cam and servo case erectors for flexibility and speed

- choice between tape and hot-melt sealing for both bottoms and tops based on shipping conditions and product weight

A well-designed case erecting and sealing section ensures that the entire end-of-line process is stable, efficient and ready to support higher throughput as demand grows.

FAQ

Q1: What is the difference between a case erector and a case sealer?

A case erector forms flat case blanks into open boxes and seals the bottom flaps, creating empty, ready-to-fill cases. A case sealer closes and seals the top flaps of cases after they have been filled with product.

Q2: When should I choose a vertical case erector instead of a horizontal one?

Choose a vertical case erector when you need higher forming stability, better case squareness and more robust performance under varying air conditions, especially at higher speeds. Vertical designs are also easier to integrate with many top-load and robotic case packers.

Q3: When is a servo case erector preferable to a purely mechanical design?

A servo case erector is preferable when you need frequent size changes, higher speeds or smoother motion, or when the erector must integrate tightly with an automatic case packer and palletizing system. Servo control allows motion profiles and timings to be adjusted via recipes instead of mechanical changes.

Q4: How do I decide between tape and hot-melt glue sealing?

Tape sealing is simple, cost-effective and suitable for many applications. Hot-melt glue provides stronger, more rigid seals and is often preferred for heavy, high-value or long-distance shipments. The final choice depends on product weight, logistics conditions and internal packaging standards, for both case bottoms and tops.

Q5: Do I need both a case erector and a case sealer?

In fully automated end-of-line packaging, yes. The case erector prepares empty cases for packing, and the case sealing machine secures filled cases for shipping. In smaller plants, some manufacturers start with only a case sealer and manually erect cases, then later add a case erector as volume increases.

Related Knowledge Articles

Overview of how case erectors, case sealers, case packers and palletizers fit into the full packaging system.

Secondary packaging step that often feeds cases with retail cartons.

Primary packaging of bars, biscuits and bakery products before case packing.

Bagging of snacks, pasta and frozen food that are later loaded into shipping cases.

Flexible pouches that are commonly packed into corrugated cases for distribution.

- Robotic Palletizing Systems for Shipping Cases (Coming soon)

How sealed cases are stacked onto pallets as the final step of end-of-line automation.