Cartoning Machine (Cartoner): From Individual Packs to Retail-Ready Cartons

Packaging Knowledge Hub

If you're seeking packaging automation solutions, please contact us, and we'll be delighted to offer you the most tailored solution.

This article is part of the Soontrue Packaging Knowledge Series under the "Packaging Machine Classification & Applications" section. For a broader view of packaging layers and machine types, see Packaging Machine Classification & Applications and Primary, Secondary & Tertiary Packaging Explained.

In many modern factories, the journey from individual packs to retail-ready units passes through one key type of equipment: the cartoning machine. A cartoning machine—also called a cartoner or cartoning packaging machine—forms cartons, loads products into them and closes the cartons at high speed. It sits between primary packaging (flow-wrapped bags, sachets, blisters, bottles, pouches) and end-of-line packaging (case packing and palletizing), making it a critical part of the secondary packaging layer.

Whether you are packing flow-wrapped biscuits into display boxes, grouping sachets into retail cartons, or loading blister packs into pharmaceutical boxes, choosing the right cartoning equipment has a major impact on line efficiency, labor needs and overall product presentation. This article explains what cartoning machines are, how they work, the main types such as horizontal cartoner and vertical cartoner, typical applications, and how they integrate with upstream and downstream automation.

1. What Is a Cartoning Machine and How Does It Work?

A cartoning machine is a packaging machine that erects flat-folded carton blanks, loads products into the open cartons, and closes the ends by tucking or gluing the flaps. The finished cartons become secondary packaging that protects primary packs, presents them on the shelf and makes them easier to handle in transport and retail.

Although designs vary, most cartoning packaging machines follow the same functional steps within one continuous or intermittent motion cycle:

Carton erection

Flat carton blanks are taken from a magazine and opened into a three-dimensional shape. A forming tool or vacuum system pulls the blank into an open carton. The bottom or side is locked or glued to keep the carton rigid.

Product infeed and loading

Products arrive from upstream equipment—such as horizontal flow wrappers, vertical packaging machines (VFFS), premade pouch packing machines or blister lines. The cartoner aligns and groups the products, then pushes or drops them into the open cartons. Depending on the machine type, this is done horizontally (end-load) or vertically (top-load).

Carton closing

After loading, the machine closes the carton flaps. Closure can be by mechanical tuck-in (locking tabs into slots), by hot-melt glue, or sometimes by a combination. The finished carton is discharged onto a conveyor for coding, inspection and case packing.

By combining these steps in one synchronized system, a cartoning machine can process anything from a few dozen cartons per minute in smaller lines up to several hundred cartons per minute in high-speed operations.

Key advantages of cartoning machines:

- Replace manual boxing with consistent, high-speed cartoning automation

- Improve product protection and retail presentation

- Enable complex pack configurations (multi-packs, counted groups, layered arrangements)

- Create a clean interface between primary packs and shipping cases

For many manufacturers, upgrading from hand-packed boxes to an automatic cartoner is one of the most impactful steps they can take in secondary packaging.

2. Types of Cartoning Equipment: Horizontal and Vertical Cartoners

The two main categories of cartoning equipment are the horizontal cartoner and the vertical cartoner. Each type is optimized for different product shapes, pack styles and industry requirements.

2.1 Horizontal cartoner (end-load)

A horizontal cartoner is the most common type of cartoning machine in food, confectionery and personal care. Cartons are carried horizontally on a transport chain, and products are pushed into the side (end) of the carton.

Typical features of a horizontal cartoner:

- Cartons are erected and placed on a horizontal conveyor with the open end facing the loading station.

- Products—such as flow-wrapped bars, bags, pouches or blister cards—are accumulated and grouped to match the required count.

- A mechanical or servo-driven pusher loads the group into the open carton from the side.

- The flaps are then closed by tuck-in or hot-melt glue.

Best suited for:

- Bars and sticks (chocolate bars, cereal bars, nougat sticks)

- Flow-wrapped biscuits and bakery items

- Sachets and pouches that can lie flat in layers

- Blister cards for healthcare and personal care products

Because product orientation is controlled on conveyors and pushers, horizontal cartoners are ideal for multi-count packs and standardized retail boxes where alignment and print-window positioning matter.

2.2 Vertical cartoner (top-load)

A vertical cartoner—or vertical cartoning machine—keeps cartons upright and loads product from the top. The cartons are either pre-erected and carried in pockets, or formed directly on the machine and held open for loading.

Typical features of a vertical cartoner:

- Cartons are erected and held with their open top facing upward.

- Products, often loose items or small bags, are dropped or placed into the cartons from above.

- After reaching the required count or fill level, top flaps are closed by tuck-in or glue.

Best suited for:

- Loose or irregular items (small candies, confectionery pieces, hardware parts)

- Small bags or sachets that are easier to gravity-feed

- Some pharmaceutical and personal care applications where top-loading simplifies handling

Vertical cartoners are often chosen when it is difficult to align products in a neat horizontal stack, or when the product orientation in the carton is less critical.

2.3 Other classification angles

Cartoning machines can also be categorized by:

- Intermittent vs continuous motion – intermittent cartoners stop cartons at each station; continuous machines run cartons and products in a synchronized, constant motion for higher speeds.

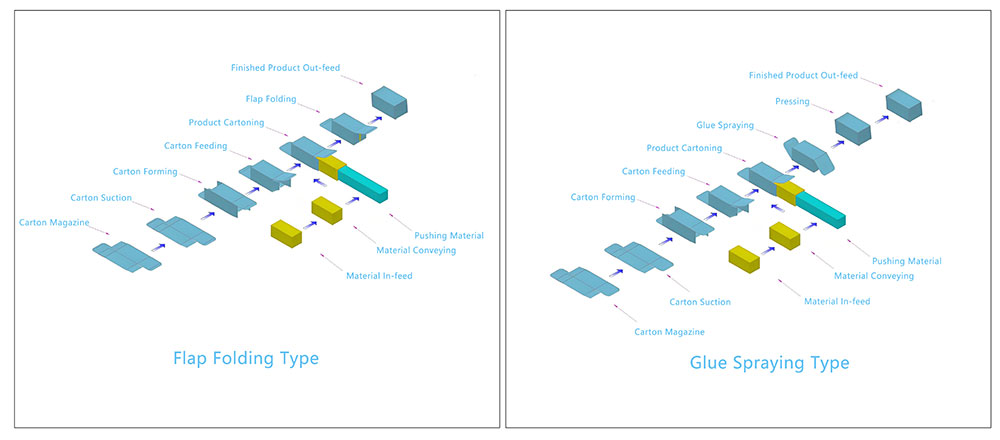

- Tuck-in vs hot-melt glue closure – tuck-in closure avoids glue and can be more sustainable; hot-melt offers stronger closure and more design freedom but uses adhesive.

- Manual, semi-automatic and fully automatic cartoners – for different stages of automation and investment.

Across all these types, modern cartoning equipment uses servo drives, PLC control and touchscreen HMIs to support recipe-based format changes, diagnostics and integration with other packaging machines.

3. Typical Applications and Packaging Formats for Cartoning Machines

Because they operate at the secondary packaging level, cartoning machines appear in many industries and handle a wide variety of product formats.

3.1 Food, bakery and confectionery

In food and bakery, a cartoner is often installed directly after a horizontal flow wrapper or a vertical packaging machine. Typical applications include:

- Packing flow-wrapped biscuits or wafers into retail cartons

- Grouping several pillow bags of snacks into a display box

- Packing multiple instant noodle bricks or sachets into a family carton

- Loading chocolate bars or confectionery trays into printed boxes

Cartons not only protect primary packs from crushing and scuffing; they also provide a larger surface for branding, nutrition information and multilingual labeling.

3.2 Pharmaceuticals and healthcare

In pharma and healthcare, cartoning packaging machines are central to secondary packaging:

- Blister cards of tablets loaded into printed cartons

- Small bottles, vials or ampoules packed into cartons with partitions or inserts

- Medical devices and OTC products boxed in tamper-evident cartons

Here, the requirements for cartoning machines include precise counting, leaflet insertion, code and lot verification, serialization printing and integration with track-and-trace systems.

3.3 Cosmetics, personal care and household products

Cosmetics and household goods often rely on cartoning equipment to:

- Pack tubes, jars or bottles into branded cartons

- Create multi-pack configurations (e.g. three-pack toothpaste cartons)

- Combine sachets or refills with promotional items in a single carton

For these industries, the key considerations include gentle handling of high-value items, consistent carton quality and flexible size adjustment to keep up with frequent marketing changes.

3.4 Industrial and B2B packaging

Beyond retail, cartoners are used in industrial and B2B environments to:

- Pack small components or hardware into labeled cartons

- Box up sample kits or test sets

- Group unit-dose packs into distribution cartons

In such cases, the emphasis is on reliability, clear identification and compatibility with downstream case packing and palletizing.

4. How Cartoning Machines Fit into Automated Packaging Lines

From a line-design perspective, a cartoning machine is a bridge between primary packaging and end-of-line operations. It often receives products from multiple upstream machines and feeds one or more downstream case packers.

A typical automated line might look like this:

Primary packaging

- Horizontal flow wrappers for bars, biscuits or bakery products

- Vertical packaging machines (VFFS) for bags of snacks, pasta or frozen products

- Premade pouch packing machines for stand-up pouches and zipper bags

- Blister packers or bottle filling lines in pharma and cosmetics

Product accumulation and distribution

- Infeed conveyors, accumulation systems and orienting devices organize products into consistent lanes and counts for cartoning.

Cartoning

- A horizontal cartoner or vertical cartoner forms cartons, loads products and closes them.

- Optional functions: leaflet insertion, printing, code verification, barcode reading and rejection of defective cartons.

Case packing and palletizing

- Wrapped or unwrapped cartons are grouped into shipping cases by a case packer or wrap-around case packer.

- Cases are then stacked onto pallets by a palletizing robot or conventional palletizer.

In many plants, cartoners are part of larger end-of-line packaging solutions that also include wrapping / overwrapping machines, case erectors, case sealers and palletizing cells. When selecting cartoning equipment, it is essential to consider not only the immediate product, but also how the cartoning machine will synchronize with upstream packers and downstream case-packing speed.

Key integration questions include:

- What is the maximum and nominal speed of the primary packaging equipment?

- Will the cartoner handle products from one or multiple lines?

- How will format changeovers be managed across the entire line?

- How will data (counts, rejects, codes) flow between machines and the line control system?

A well-integrated cartoning machine helps stabilize the secondary packaging section, reduce manual labor in boxing, and support traceability from individual packs through to cases and pallets.

FAQ

Q1: What is the difference between a horizontal cartoner and a vertical cartoner?

A horizontal cartoner loads products into cartons from the side (end-load) and is ideal for stacked products like bars, flow-packs and blister cards. A vertical cartoner loads from the top (top-load) and is better for loose or irregular items that can be dropped or placed into upright cartons.

Q2: How do I choose between tuck-in and hot-melt glue closure?

Tuck-in closure avoids glue and can be more sustainable, but requires precise carton design and may offer less tamper resistance. Hot-melt glue provides stronger closure, higher tamper evidence and more design flexibility, but uses adhesive and requires glue system maintenance.

Q3: Can one cartoning machine handle multiple carton sizes?

Yes. Modern cartoning machines are designed for a range of carton sizes within defined limits. With the right change parts and servo adjustments, operators can switch between formats using recipe settings and limited mechanical changeover.

Q4: How does cartoning equipment integrate with flow wrappers and VFFS machines?

Flow-wrapped or bagged products are conveyed and accumulated into groups that match the carton configuration, then transferred into the cartoner. Properly designed infeed systems and line controls ensure synchronized speeds and smooth product flow.

Q5: When is it time to move from manual boxing to an automatic cartoner?

Signs include high labor cost in boxing, inconsistent pack counts, quality issues in carton appearance, and bottlenecks in secondary packaging. At that point, investing in a cartoning packaging machine can significantly increase throughput and improve consistency.

Related Knowledge Articles

Overview of how cartoners fit alongside flow wrappers, VFFS, premade pouch machines and case packers in the overall packaging system.

Common upstream equipment feeding flow-wrapped products into cartoning machines.

How vertically bagged products are grouped into cartons for secondary packaging.

When stand-up pouches need to be loaded into retail-ready cartons or display boxes.

Optional secondary operations that add film overwrap and tamper evidence to finished cartons.

How cartons are grouped into shipping cases and integrated into palletizing systems.