Case Packer Machine for Automatic Shipping Case Packing

Packaging Knowledge Hub

If you're seeking packaging automation solutions, please contact us, and we'll be delighted to offer you the most tailored solution.

This article is part of the Soontrue Packaging Knowledge Series under the "Packaging Machine Classification & Applications" section. For a broader view of packaging layers and machine types, see Packaging Machine Classification & Applications and Primary, Secondary & Tertiary Packaging Explained.

After primary and secondary packaging are complete—pillow bags, VFFS bags, premade pouches, cartons or overwrapped boxes—products still need to be loaded into shipping cases for storage and distribution. This critical step is handled by the case packer machine, also called an automatic case packing machine, carton case packer or end-of-line case packer.

A case packer automatically collates products into predefined patterns and loads them into corrugated cases or trays. It forms the bridge between upstream packaging equipment (flow wrappers, VFFS machines, premade pouch packing machines, cartoners, overwrapping machines) and downstream case sealing, palletizing and warehouse logistics. Choosing the right case packing machine directly affects line efficiency, labor requirements, product protection and pallet stability.

This article explains what case packers are, how they work, the main types—side-load, top-load, wrap-around, robotic and vision-guided case packers—typical applications and case patterns, and how they fit into fully automated end-of-line packaging systems.

1. What Is a Case Packer and How Does It Work?

A case packer is an automatic machine that groups individual products or secondary packs into sets and loads those sets into corrugated cases or trays in a controlled, repeatable way. Compared to manual packing, an automatic case packer offers higher speed, consistent pack patterns and better ergonomics for operators.

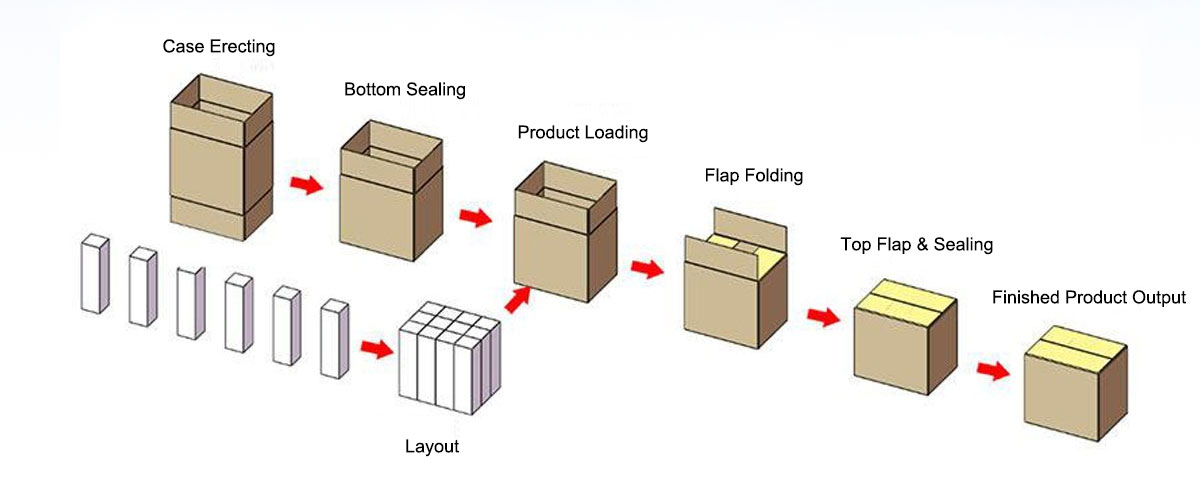

Although designs vary, most case packing machines follow four core steps:

- Case infeed

Empty cases or trays arrive from a case erector. They may be open-top RSC cases, wrap-around blanks or trays with or without lids. The case packer positions these cases at the loading station.

- Product infeed and collation

Products arrive from upstream equipment—such as horizontal flow wrappers, VFFS packaging machines, premade pouch packing machines, cartoners or overwrapping machines. Conveyors, lane dividers and accumulation systems organize the flow and collate products into groups that match the desired case pattern (for example 3×4, 4×6, layered patterns or mixed packs).

- Loading into cases

Depending on the case packer design, grouped products are pushed from the side, lowered from the top, wrapped together with the case blank or placed by a robot into the open case or tray.

- Discharge to case sealing and palletizing

Once filled, cases leave the loading station and move to a case sealing machine for top sealing with tape or hot-melt glue, then continue to palletizing.

By automating these steps, a case packing system can run at constant speed with defined case patterns, reducing manual handling and making the entire end-of-line area more stable and predictable.

2. Main Types of Case Packer Machines

Case packers can be classified in several ways. From a practical engineering perspective, the most important dimensions are loading direction (side-load vs top-load), case style (RSC vs wrap-around), and whether the machine is robotic, mechanical or vision-guided.

2.1 Side-load case packer

A side-load case packer (also called a horizontal case packer) pushes grouped products horizontally into the open side of an RSC case or tray.

Key characteristics:

- Products are collected on a loading platform in front of the open case.

- A mechanical or servo-driven pusher loads the entire group into the case in one stroke.

- Well suited to products that can be stacked and slid, such as cartons, flow-wrapped packs, pouches in brick form, multipacks and rigid containers.

Best suited for:

- Cartoned biscuits, chocolate, confectionery and snack packs

- Flow-wrapped bakery products or bars

- Rigid or semi-rigid containers that can tolerate horizontal pushing

Side-load case packers are common in food and consumer-goods plants where products already have a stable secondary package (e.g. cartons) and need to be tightly packed into shipping cases.

2.2 Top-load case packer

A top-load case packer loads products from above into an open case or tray. The loading motion can be performed by a mechanical pick-and-place head, a servo gantry or a robotic case packer.

Key characteristics:

- Cases or trays are positioned beneath the loading head.

- Products are collated and then picked from the infeed and placed vertically into the case according to a defined pattern.

- Gentle handling is possible because products are placed rather than pushed.

Best suited for:

- Fragile or irregular products that cannot be pushed horizontally

- Mixed-product cases (for example assorted flavors or sizes)

- Premium cartons, overwrapped boxes and products where orientation is important

Top-load designs are also popular when integrating collaborative robots or delta robots into the case-packing cell, enabling flexible patterns and fast changeovers via software recipes.

2.3 Wrap-around case packer

A wrap-around case packer forms the case around the product group. Instead of loading products into a pre-erected RSC case, the machine feeds a flat wrap-around blank, collates the products on the blank and then folds and closes the blank around the group.

Key characteristics:

- Higher stability and material efficiency compared with standard RSC cases in many applications

- Tight fit around products, improving pallet stability and sometimes reducing corrugated usage

- Suitable for bottles, cans, cartons and multipacks arranged in regular patterns

Wrap-around case packers are often used in beverage, dairy, canned-goods and high-volume consumer-goods lines where case design and pallet patterns are optimized as a whole.

2.4 Robotic case packer vs mechanical case packer

Many modern end-of-line systems use robotic case packers, where industrial or collaborative robots handle product picking, orientation and placement into cases. Compared to purely mechanical case packers, robotic systems offer:

- higher flexibility for SKU changes and different case patterns

- easier handling of irregular or fragile products

- potential to combine several tasks (sorting, orienting, packing) in one cell

Mechanical case packing machines still have advantages for very high-speed, standardized products, where a dedicated cam or servo mechanism can outperform a robot in terms of raw cycles per minute.

In practice, many factories adopt a hybrid approach: mechanical grouping and transport with robotic case packing for the final placement, especially for mixed packs or frequently changing assortments.

2.5 Vision-guided case packing for irregular products and cases

As product portfolios become more diverse, many factories face a new challenge: irregular products, random infeed and non-standard cases that are difficult to handle with purely mechanical case packers. This is where vision-guided robotic case packing becomes a powerful option.

In a vision-guided case packer, one or more cameras or 3D sensors detect the position, orientation and sometimes even the shape of incoming products on the conveyor. A vision system identifies valid pick points and calculates how each item should be oriented inside the case. A robotic arm then picks the products and places them into the case according to a flexible, software-defined pattern.

Typical use cases include:

- soft or irregular bags and pouches that do not behave like rigid bricks

- mixed or randomized products coming from a common conveyor

- bakery items in trays, stand-up pouches or doypacks that need controlled orientation

- non-standard or irregular cases, shelf-ready trays or display cases with cut-outs

Because the pattern is defined in software, vision-guided case packing can adapt quickly to new SKUs, packaging formats and promotional layouts without large mechanical changes. This approach combines robotic case packing with machine vision, making it easier to automate complex packing tasks that were traditionally left to manual operators.

In many modern end-of-line projects, a vision-guided robotic case packer is installed as a flexible cell that can support multiple upstream packaging machines, handle irregular products and feed sealed cases directly to robotic palletizing.

3. Typical Applications and Case Patterns

Because they work at the shipping carton level, case packers are used across almost all industries that ship products in corrugated cases.

3.1 Food, bakery and confectionery

Typical case-packing applications include:

- loading flow-wrapped biscuits, wafers or cookies into RSC cases

- packing bags of snacks, chips or nuts into shipper cases or display cases

- grouping chocolate bars, confectionery cartons or overwrapped gift boxes into shipping cases

- building family packs or assortment cases with mixed flavors

Cases may be standard RSC cartons, tray-and-lid combinations or shelf-ready display cases designed to open easily at retail.

3.2 Coffee, tea, beverage and powdered products

In coffee, tea and beverage, case packer machines handle:

- overwrapped tea cartons or coffee cartons packed into cases for distribution

- premade pouches of coffee or powdered drink mixes packed into corrugated shippers

- small bottles, cans or bricks packed into wrap-around or tray-and-shrink formats

Here, case pattern and pallet pattern design are tightly linked, especially for export pallets and automated warehouses.

3.3 Household, personal care and pharmaceuticals

For household and personal care:

- case packers load cartons of toothpaste, cosmetics or cleaning products into shipping cases

- top-load case packers handle fragile or high-value products that require gentle placement

In pharmaceuticals and healthcare:

- serialized medicine cartons are packed into cases that later feed aggregation and track-and-trace systems

- medical device kits and diagnostic packs are loaded into cases with specific orientation and count rules

3.4 Typical case patterns

Common case patterns in automatic case packing include:

- regular grid patterns (e.g. 3×4, 4×5, 4×6)

- alternating or brick patterns for better interlocking

- multi-layer cases with interlayer pads

- mixed-SKU or assortment cases for promotional or e-commerce orders

The case packer recipe defines how many products go into each layer, how layers are stacked and how orientation is controlled.

4. Case Packers in End-of-Line Packaging Systems

A case packer machine is a central component of end-of-line packaging, connecting upstream packers and downstream palletizing. It is usually positioned between the case erector and the case sealer.

A typical end-of-line configuration looks like this:

Products are packed by horizontal flow wrappers, vertical packaging machines (VFFS), premade pouch packing machines, cartoning machines or overwrapping machines.

- Case forming

A case erector forms and bottom-seals RSC cases or prepares wrap-around blanks. Cases are positioned at the case packer infeed.

- Case packing

The case packer collates products, forms the required pack pattern and loads products into the open cases, or forms wrap-around cases around them.

- Case sealing

Filled cases move to a case sealing machine where top flaps are folded and sealed with tape or hot-melt glue.

- Palletizing and stretch wrapping

Sealed cases are conveyed to a palletizing robot or layer palletizer, then wrapped and labeled for storage or shipment.

When designing an automated end-of-line section, manufacturers should consider:

- speed and buffer capacity between upstream packaging and the case packer

- choice of case style (RSC vs wrap-around vs tray-and-lid)

- required flexibility for SKU changes, case patterns and mixed-SKU packing

- available floor space and line layout for side-load vs top-load case packing

- whether a robotic or vision-guided case packer is needed for irregular products

- integration of the case packing machine with case erectors, sealers, palletizers and warehouse systems

A well-selected case packer stabilizes the entire end-of-line area, reduces manual handling and ensures cases arrive at palletizing with consistent fill and alignment.

FAQ

Q1: What is the difference between side-load and top-load case packers?

A side-load case packer pushes grouped products horizontally into the case and is suitable for stable, stackable products such as cartons and flow-wrapped packs. A top-load case packer loads products from above, often using robotic pick-and-place, and is better for fragile, irregular or high-value products that require gentle handling.

Q2: When should I choose a wrap-around case packer?

Choose a wrap-around case packer when you want tight, material-efficient cases and high pallet stability, especially for bottles, cans or regularly shaped packs. Wrap-around designs are common in beverage and canned-food lines.

Q3: What are the advantages of a robotic case packer?

A robotic case packer offers high flexibility for product orientation, mixed-SKU cases and frequently changing pack patterns. It is ideal when you have many SKUs, irregular products or need to combine sorting, orienting and packing in a single cell.

Q4: What is vision-guided case packing used for?

Vision-guided case packing combines machine vision with robotic case packing to handle irregular products, random infeed and non-standard cases. Cameras or 3D sensors locate products and calculate pick points so the robot can place them accurately into the case, even when orientation or position varies.

Q5: When is it time to move from manual case packing to an automatic case packer?

Warning signs include high labor cost in case packing, bottlenecks at the end of the line, inconsistent case fills and safety or ergonomic concerns for operators. At that point, investing in an automatic case packing machine can significantly improve throughput and consistency.

Related Knowledge Articles

- Case Erecting & Case Sealing Machines: Forming and Closing Shipping Cartons

How empty cases are formed and sealed around the case-packing step.

Secondary packaging stage that often feeds cartons into case packers.

Primary packaging of bars, biscuits and bakery products before case packing.

Bagging of snacks, pasta or frozen food that are later loaded into cases.

Stand-up pouches and zipper bags that usually require case packing for distribution.

- Robotic Palletizing Systems for Shipping Cases (Coming soon)

How packed and sealed cases are stacked onto pallets as the final step in end-of-line automation.