Vertical Packaging Machines (VFFS): Hygienic, High-Efficiency Packing Solutions

Packaging Knowledge Hub

If you're seeking packaging automation solutions, please contact us, and we'll be delighted to offer you the most tailored solution.

This article is part of the Soontrue Packaging Knowledge Series under the "Packaging Machine Classification & Applications" section. For a broader overview of the basics, see Packaging Machine Definition & History.

In many factories, the core of vertical packaging is the vertical packaging machine, also known as a vertical packing machine or VFFS (vertical form-fill-seal) machine. From snack foods and frozen products to powders, granules and liquids, VFFS technology has become one of the most important vertical packaging solutions for manufacturers who need high speed, flexible formats and reliable sealing performance.

A modern vertical packaging machine does much more than simply fill bags. It must support hygienic vertical packaging for food and sensitive products, handle different bag styles and film materials, and integrate smoothly into complete vertical packaging systems with weighing, inspection and end-of-line equipment. This article explains what VFFS machines are, how they work, where vertical pouch packaging is typically used, and how packaging automation vertical can help improve efficiency in your plant.

1. What Is a Vertical Packaging Machine (VFFS) and How Does It Work?

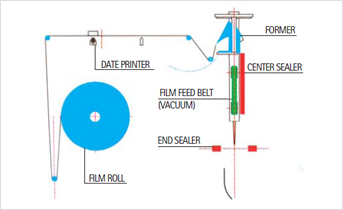

A vertical packaging machine is a fully automatic system that forms a bag from flat roll film, fills it with product, and seals it—all in a continuously repeating high-speed cycle. The film moves downward, products are dropped vertically by gravity, and finished packs are discharged at the bottom. This makes VFFS technology ideal for free-flowing products and applications where vertical filling is the most efficient method.

In a typical vertical packing machine, the process is precise and synchronized: film is unwound from the roll, tensioned, and guided over a forming shoulder to create a tube around a forming pipe. Vertical sealing jaws create the longitudinal seal at the back of the bag. At the same time, a dosing or weighing system releases product through the forming tube. Horizontal sealing jaws then close to create the top seal of one bag and the bottom seal of the next, cutting the film at the correct length. Through this optimized motion, Soontrue's high-speed VFFS models can reach up to 120 bags per minute (BPM), significantly outperforming standard manual packing while maintaining consistent weight and seal integrity.

The same basic principle supports a wide range of vertical packaging machines with different sealing jaw designs, servo control levels, and bag styles. For many manufacturers, a VFFS is the most economical way to transition from manual filling into high-efficiency, fully automatic food packaging solutions.

2. Hygienic Vertical Packaging for Food and Sensitive Products

As food safety standards and regulatory requirements continue to tighten, hygienic vertical packaging has become a key selection criterion for equipment. A VFFS machine used in the food industry must be designed to prevent contamination, resist corrosion, and eliminate "product traps" where crumbs, powders, or liquids can accumulate.

Modern hygienic vertical packaging machines from Soontrue are engineered to meet strict HACCP and GMP principles. Key sanitary features include:

- Full Stainless Steel 304 Construction: The machine frame and product-contact parts are built from high-grade stainless steel to ensure durability and corrosion resistance against acidic or salty foods.

- IP65 Waterproof Rating (Wash-down Ready): The electrical enclosures and drive units are sealed against dust and water, allowing for high-pressure wash-downs without risking component failure.

- Open Frame Design & Smooth Welds: Rounded corners and an open architecture allow water and cleaning agents to drain away freely, preventing residue build-up and bacterial growth.

- Tool-free Disassembly for Cleaning: The forming set, sealing jaws, and film carriage can be removed quickly without tools, significantly reducing downtime during sanitation cycles.

For products such as snacks, nuts, frozen vegetables, grated cheese, spices, coffee, and milk powder, a hygienic vertical packaging machine is usually integrated with a multihead weigher or auger filler. Additional equipment such as metal detectors and gas flushing units can be added to build a complete system that protects product quality, extends shelf life, and supports traceability.

3. Bag Types, Products and Typical Applications in Vertical Pouch Packaging

One of the reasons vertical pouch packaging is so popular is its flexibility. The same machine frame can often produce different bag styles with change parts and recipe adjustments, allowing manufacturers to serve multiple markets from one line.

Common bag types include classic pillow bags, gusseted bags, block-bottom or quad-seal bags, and small sachets. With appropriate forming sets, some VFFS models can also support small vertical pouch packaging formats for single-serve portions. By combining different forming tubes, sealing jaw patterns and cutting tools, manufacturers can adjust bag size and film usage to balance brand appearance with material cost.

Typical products handled by vertical packaging machines include:

Granules and snacks – chips, nuts, extruded snacks, candy pieces, cereal and pet food

Powders – coffee, flour, sugar, spices, premixes, instant drinks and nutrition powders

Small solids – rice, beans, seeds, frozen vegetables, dumplings and meat pieces

Liquids and pastes (with pump systems) – sauces, dressings, soup bases and condiments

Because a vertical packaging machine uses gravity to assist filling, it can achieve high speeds with stable weight control when paired with suitable dosing systems. For many factories, adding a VFFS is the quickest way to introduce vertical packaging solutions for new SKUs or to expand capacity in existing product lines.

4. Vertical Packaging Systems and Packaging Automation in the Factory

In real plants, a VFFS rarely works alone. It is usually the center of a complete vertical packaging system that starts with feeding and ends with palletizing. Upstream, automatic feeding conveyors, vibratory feeders or elevator systems bring products to the weigher or filler. Downstream, finished bags may pass through checkweighers, metal detectors, x-ray inspection, labelers and printers before entering secondary and tertiary packaging.

This is where packaging automation vertical really shows its value. When a vertical packaging machine is integrated with multihead weighers, case packers and palletizing cells, the entire process from dosing to pallet can run with minimal manual handling. Line control software and PLC systems coordinate speeds and product flow to reduce bottlenecks and downtime. Recipe-based changeovers allow operators to switch between bag sizes or products quickly, enabling shorter production runs and more flexible scheduling.

For manufacturers that want to upgrade step by step, it is common to begin with a standalone vertical packaging machine, then gradually add feeding, inspection and end-of-line equipment, building a more complete vertical packaging system over time. Choosing machines that are designed from the start for integration makes this journey smoother and protects the investment.

Conclusion

A vertical packaging machine remains one of the most important tools for high-efficiency, hygienic packaging in food and many other industries. By understanding how VFFS technology works, what kinds of products and bag styles it can handle, and how it fits into larger vertical packaging systems, manufacturers can design smart, scalable vertical packaging solutions that support both present and future needs.

Whether your priority is hygienic vertical packaging for sensitive products, flexible format changes for new SKUs, or full packaging automation vertical that connects dosing, bagging and case packing into one continuous flow, choosing the right VFFS machine and integration partner will have a direct impact on productivity, quality and ROI.

FAQ

Q1: What is the speed of Soontrue's high-speed vertical packaging machine?

Soontrue's high-speed VFFS models can reach up to 120 bags per minute (BPM). This fully automatic cycle significantly outperforms manual packing while maintaining consistent weight and seal integrity, making it ideal for high-volume production lines.

Q2: Are your vertical packaging machines suitable for hygienic food production?

Yes. Our hygienic models are designed with full Stainless Steel 304 construction and feature an IP65 waterproof rating (wash-down ready). The open-frame design prevents residue build-up, making them fully compliant with HACCP and GMP principles for food safety.

Q3: Can the same VFFS machine handle different bag sizes and products?

Yes. Modern vertical packaging machines use servo drives and recipe management to change bag lengths, forming tubes, and filling parameters quickly. With the right design, one line can run multiple SKUs (like pillow bags or gusseted bags) with reasonable changeover time.

Q4: What is the difference between vertical and horizontal packaging machines?

A vertical packing machine fills from the top using gravity and is ideal for free-flowing products (granules, powders, liquids). A horizontal flow wrapper feeds products horizontally and is better for solid, individual items like biscuits and bars. Both have their place in a complete packaging strategy.

Q5: What should I consider when selecting a vertical packaging solution?

Key factors include your target speed (e.g., high-speed requirements), product characteristics, hygiene levels (wash-down needs), and available floor space. Contact Soontrue's engineers to find a solution that integrates perfectly into your existing line.

Related Knowledge Articles

Overview of how vertical, horizontal, premade pouch, cartoning and case-packing machines fit into different packaging levels.

When horizontal flow wrappers are a better choice than VFFS for certain products.

For premium doypack and zipper pouch formats that go beyond standard vertical bags.

How vertically packed bags are grouped into cartons as secondary packaging.

From VFFS bags to shipping cases and pallets in a fully automated line.

Foundation article explaining the broader FFS concept behind both vertical and horizontal solutions.