Pillow Packing Machines (Horizontal Flow Wrappers): Types, Working Principles & Applications

Packaging Knowledge Hub

If you're seeking packaging automation solutions, please contact us, and we'll be delighted to offer you the most tailored solution.

This article is part of the Soontrue Packaging Knowledge Series under the "Packaging Machine Classification & Applications" section. For a broader overview of packaging machine definitions and history, see Packaging Machine Definition & History.

In modern manufacturing, many products—from biscuits and bread to medical devices and hardware—are packed in a simple, neat pillow bag. Behind this familiar pack style is a highly versatile machine: the pillow packing machine, also known as a horizontal flow wrapper or pillow type packaging machine. For factories facing rising labor costs, inconsistent packaging quality, and the need for higher output, a well-designed pillow packaging machine can become the core of an efficient, fully automated line.

This guide explains what a pillow pack machine is, how it works, the difference between rotary and box-motion models, typical industry applications, key technologies and market trends, and how to choose a reliable pillow packing machine manufacturer.

1. What Is a Pillow Packing Machine? Working Principle & Key Advantages

A pillow packing machine is a type of horizontal flow wrapping machine that forms film into a tube around the product, seals it on three sides, and cuts it into individual packs. Products are fed horizontally on an infeed conveyor, making this solution ideal for solid items such as bakery products, confectionery, instant noodles, daily goods, and many non-food items.

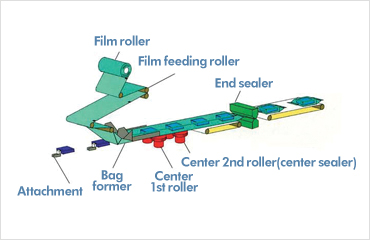

Working principle in simple terms

- Products are carried in a single or multiple lanes on an infeed conveyor.

- A film roll is unwound and guided around a forming box, wrapping the film around the product flow to create a tube.

- A longitudinal sealing unit forms the back seal of the pillow bag.

- End-sealing jaws create the cross seals and cut the film, producing finished packs at a consistent length.

Because forming, sealing, and cutting happen continuously, flow pack machines can achieve very high speeds while keeping the footprint compact.

Key advantages of pillow packing machines

- High speed & efficiency – Modern pillow packing machines can pack hundreds of units per minute, making them ideal for high-volume production lines.

- Wide product range – The same pillow packaging machine can handle different lengths, heights, and shapes with format changes.

- Consistent, attractive packs – Neat pillow bags with stable seals improve shelf presentation and protect the product.

- Automation-ready – Easily integrated with automatic feeding systems, multi-lane sorting, cartoners, case packers, and palletizing systems, forming a full packaging line.

- Lower labor cost – Replaces manual wrapping and counting with continuous, stable output.

For many factories, upgrading from manual or semi-automatic packing to a fully automatic pillow packing machine is the first step towards intelligent packaging automation.

2. Rotary vs Box-Motion Pillow Packing Machines

Within the pillow pack machine family, there are two main sealing motion types: rotary and box-motion. Understanding the difference is essential when choosing equipment or planning future upgrades.

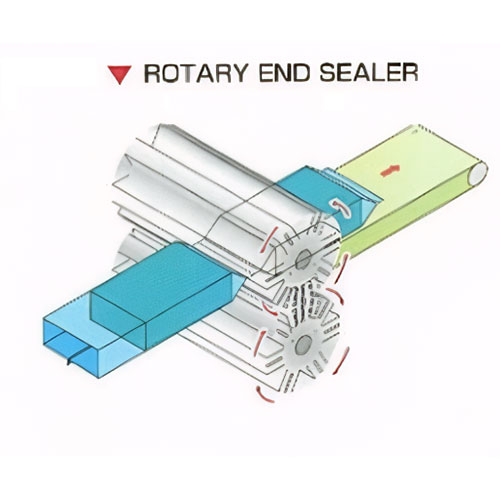

Rotary pillow packing machines (continuous motion)

A rotary pillow packing machine uses continuously rotating end-sealing jaws. The jaws rotate in synchronization with the film and product flow, sealing and cutting without stopping.

Typical features

- Designed for high-speed production and continuous operation

- Best suited for uniform products with stable shapes and sizes

- Ideal for items like biscuits, cookies, cereal bars, candy, chocolate bars, and regular bakery items

Advantages

- Very high output and smooth product flow

- Lower cost per pack at scale

- Proven technology for many food manufacturers

Considerations

- Less tolerant of irregular products or large height variations

- Limited sealing time compared with box-motion systems, so not ideal for very thick films or complex laminates requiring long dwell times

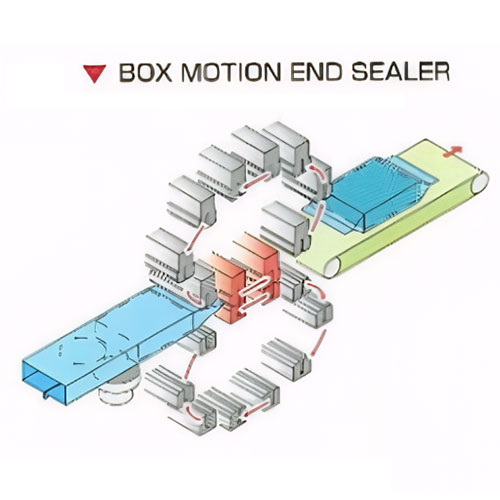

Box-motion pillow packing machines (intermittent motion)

A box-motion pillow packing machine (also called a reciprocating flow wrapper) uses end-sealing jaws that move with the film, stop to apply pressure and heat, then return. The movement path is more like a box shape rather than pure rotation.

Typical features

- Designed for superior sealing quality and flexibility

- Especially suitable for thicker films, high-barrier materials, or products demanding hermetic seals

- Often used for medical products, high-value snacks, frozen foods, and items with irregular shapes

Advantages

- Longer dwell time for sealing → stronger, more airtight seals

- Better performance on thick or multilayer films

- More tolerant of variable product sizes and heights

Considerations

- Maximum speed is usually lower than a high-end rotary model

- Mechanical structure is more complex, though modern servo systems make operation and maintenance easier

How to choose between rotary and box-motion

In general:

- If your priority is maximum speed with standardized products → choose a rotary pillow packing machine.

- If your priority is seal integrity, flexibility, and film compatibility → consider a box-motion pillow packing machine.

Many manufacturers eventually run both types in different lines or plants: rotary models for mainstream, high-speed SKUs and box-motion models for premium or sensitive products.

3. Typical Industry Applications of Pillow Packing Machines

Because of their flexibility, pillow pack machines are used across many industries. Below are some of the most common application scenarios.

Food industry

The food sector is the largest user of pillow packaging machines. Typical products include:

- Biscuits and cookies

- Bread, buns, and pastries

- Cakes and Swiss rolls

- Instant noodles and noodle bricks

- Candy, chocolate, and cereal bars

- Frozen foods, dumplings, meat portions, and ready-to-cook items

In these applications, horizontal flow wrappers protect products from contamination and moisture while creating a consistent look on the shelf. Rotary machines dominate high-speed snack and biscuit lines, while box-motion models are widely used for high-value bakery and frozen foods requiring strong seals or MAP/N₂ flushing.

Pharmaceutical & medical products

In pharmaceutical and medical packaging, pillow packing machines are used for:

- Medical masks and respirators

- Syringes and small medical devices

- Sterile pouches (when integrated into controlled environments)

- OTC health products, plasters, or small boxes

Here, sealing integrity, lot tracking, and compliance with GMP and other regulatory standards are critical. Box-motion flow wrappers with precise temperature control, validated sealing parameters, and integration with printing & vision inspection systems are often preferred.

Daily necessities & industrial products

For non-food items, pillow type packaging machines are widely used for:

- Toothbrushes, razors, and hygiene products

- Stationery and office supplies

- Hardware components and fittings

- Small electronic accessories and cables

The goal is to provide dust protection, tamper evidence, and easier counting and distribution. In many cases, pillow packs also help prevent parts from scratching each other during transport.

Emerging and niche applications

As the pillow packing machine market evolves, more industries use horizontal flow wrappers for:

- Single-serve condiment packs in catering and airline meals

- Small agricultural products like seed packs or mini tools

- Promotion bundles combining multiple items into one retail pack

This breadth of applications is one of the main reasons pillow packing technology remains a core investment for manufacturers around the world.

4. Key Technologies, Market Trends & Choosing a Reliable Manufacturer

The global pillow packing machine market continues to shift towards higher automation, smarter controls, and more flexible formats. Understanding the technology trends helps you make better long-term decisions when selecting equipment and partners.

Core technologies in modern pillow packing machines

- Servo motor control – Used for infeed conveyors, film pulling, and sealing jaws to ensure precise synchronization and easy speed adjustments.

- PLC & HMI systems – Intuitive touchscreens allow operators to switch recipes, adjust parameters, and monitor alarms quickly.

- Photoelectric tracking – Ensures film registration marks are aligned, reducing film waste and keeping print centered on each pack.

- Automatic film splicing and tension control – Minimizes downtime when changing rolls and keeps seal quality stable.

- Integration with upstream and downstream equipment – Automatic feeders, multi-row sorting systems, cartoners, and case packers can be linked to create a continuous packaging line.

Market trends shaping pillow packing machine development

- Higher flexibility – The ability to handle multiple product sizes and formats on one line with fast changeovers.

- Smarter diagnostics – Remote monitoring, error logs, and predictive maintenance functions.

- Energy and film savings – Optimized sealing systems and motion profiles to reduce energy consumption and material waste.

- Hygienic design – Especially for food and healthcare applications: stainless steel frames, open designs, and washdown options.

As more factories move towards smart manufacturing, pillow packing machines increasingly serve as central nodes in fully automated packaging cells.

How to choose a pillow packing machine manufacturer

Selecting the right pillow packing machine manufacturers is just as important as choosing the technical specification itself. When evaluating suppliers, consider:

- Experience and installed base – Does the supplier have proven solutions in your industry (e.g., bakery, noodles, snacks, pharma)?

- Machine portfolio and scalability – Can they offer both rotary and box-motion models, multi-lane systems, and complete end-of-line packaging solutions?

- Technical support and after-sales service – Availability of overseas engineers, online support, spare parts, and training.

- Integration capability – Ability to connect the pillow packer with feeding systems, cartoners, and palletizing robots.

- Compliance and certifications – CE marking and experience with GMP, HACCP, or other relevant standards.

A trustworthy pillow packing machine manufacturer should not only sell a machine, but also help analyze your products, packaging formats, and future expansion plans to design a scalable solution.

Conclusion

The pillow packing machine—or horizontal flow wrapper—remains one of the most versatile and widely used packaging machines in modern manufacturing. By understanding how pillow pack machines work, the difference between rotary and box-motion models, and where they fit in different industries, manufacturers can make more confident decisions on equipment selection and line design.

As the pillow packing machine market continues to evolve, choosing a reliable pillow packing machine manufacturer with strong automation expertise, robust after-sales support, and the ability to integrate complete lines is crucial. With the right partner and equipment, factories can achieve higher efficiency, lower labor costs, better packaging quality, and a more competitive position in their markets.

FAQ

Q1: Is a pillow packing machine the same as a flow wrapping machine?

Yes. A pillow packing machine is a type of horizontal flow wrapper that produces pillow-style bags. The terms pillow packing machine, pillow packaging machine, pillow pack machine, and flow pack machine are often used interchangeably.

Q2: How do I decide between a rotary and box-motion pillow packing machine?

Choose a rotary pillow pack machine if you need very high speeds and handle relatively uniform products. Choose a box-motion model if you need better sealing quality, handle thicker films, or pack products with variable sizes and higher hygiene requirements.

Q3: Can pillow packing machines be connected to other packaging equipment?

Absolutely. Modern pillow packing machines are designed to integrate with automatic feeding lines, cartoners, case packers, checkweighers, and palletizing systems, forming a complete automatic packaging solution.

Q4: Are pillow packing machines suitable for small or growing businesses?

Yes. Many manufacturers offer compact or entry-level pillow pack machines that are cost-effective but still provide automated, consistent packaging—ideal for small to medium-size factories that plan to scale.

Q5: What information should I prepare before contacting a pillow packing machine manufacturer?

Prepare basic data such as product dimensions and shape, target output (packs per minute), packaging film type, desired bag dimensions, whether nitrogen flushing or MAP is needed, and any hygiene or certification requirements. This helps the supplier design a fitting solution quickly.

Related Knowledge Articles

Overview of how flow wrappers, VFFS machines, premade pouch machines, cartoners and case packers fit into different packaging levels.

- Horizontal vs Vertical Packaging Machines: Basic Comparison (Coming soon)

Simple guide to when to choose a horizontal flow wrapper versus a vertical form-fill-seal (VFFS) machine.

Explains how VFFS machines work, common bag types and when they are a better choice than pillow packing machines.

Doypack, zipper pouch and flat pouch solutions for products that need more premium formats than standard pillow bags.

How pillow-packed products are grouped into cartons as secondary packaging for retail and logistics.

- Case Packers & End-of-Line Automation for Pillow Packs

From flow-wrapped bags to shipping cases and pallets – typical end-of-line solutions for pillow-packed products.