Soontrue provides complete dumpling packaging solutions:

- Primary Packaging

- Frozen product pillow pack machines for dumplings in pillow bags (retail 200g–1kg).

- Vertical form-fill-seal (VFFS) machines for bulk dumpling packs (2kg–5kg).

- Premade pouch machines for zipper and stand-up pouches with branding.

- IQF-compatible systems ensuring smooth transfer from freezing to packaging.

- Secondary Packaging

- Carton packers for retail multipacks and export cartons.

- Case sealers & palletizers for frozen logistics and container shipments.

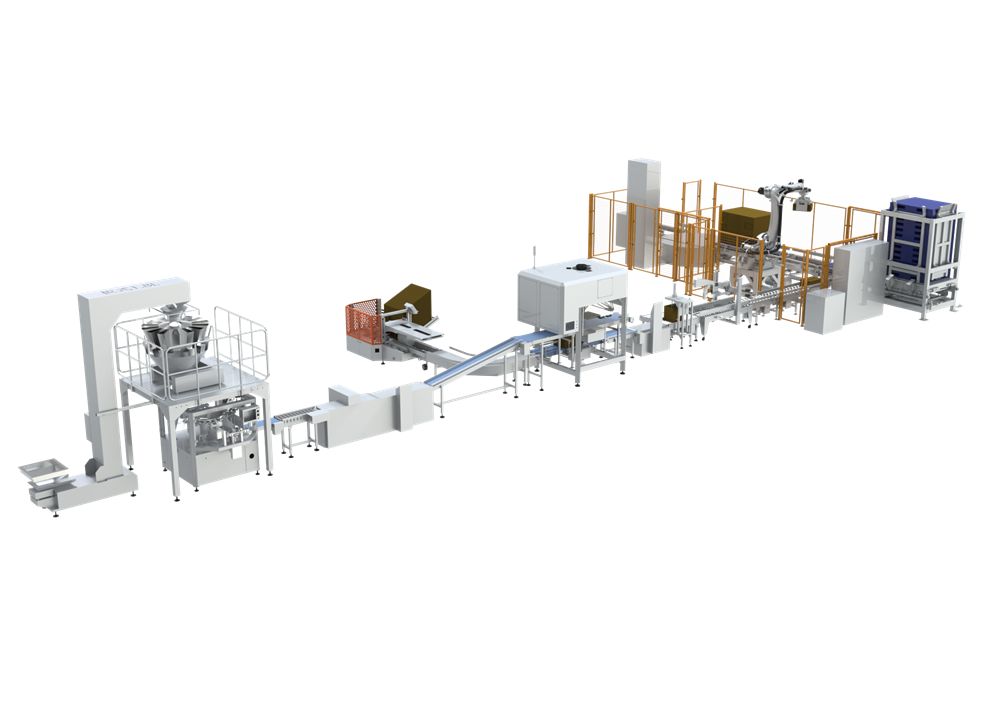

- Automated packing lines for large-scale dumpling factories.

Why Choose Soontrue for Dumpling Packaging Solutions?

- Cold-chain ready designs for frozen food environments.

- Gentle product handling to protect dumpling shape and texture.

- Flexible formats from retail pillow bags to bulk export cartons.

- High-speed automation for frozen food factories.

- End-to-end solutions integrating primary and secondary packaging.

Customer Cases

- A frozen dumpling producer used Soontrue's pillow pack machines, producing 500g–1kg retail packs.

- An exporter integrated VFFS bulk bagging and palletizing systems for 5kg dumpling bags.

- A premium brand adopted premade pouch machines for zipper pouches of artisanal dumplings.

FAQ About Dumpling Packaging Solutions

Q1: What machines are suitable for dumpling packaging?

A: Soontrue provides pillow pack, VFFS, and premade pouch machines for frozen dumplings.

Q2: Can your machines connect to IQF freezing lines?

A: Yes. Our solutions integrate smoothly with IQF frozen food production lines.

Q3: Do you also provide packaging for frozen ready meals?

A: Our focus is on dumplings and frozen dough products. Ready meals often require tray sealing or MAP systems, which are outside our main equipment range.

Q4: How do you prevent freezer burn in dumpling packs?

A: By using moisture-proof laminated films and stable sealing systems.

Q5: Can small dumpling packs be grouped for export?

A: Yes. We offer carton and palletizing systems for multipack and bulk logistics.