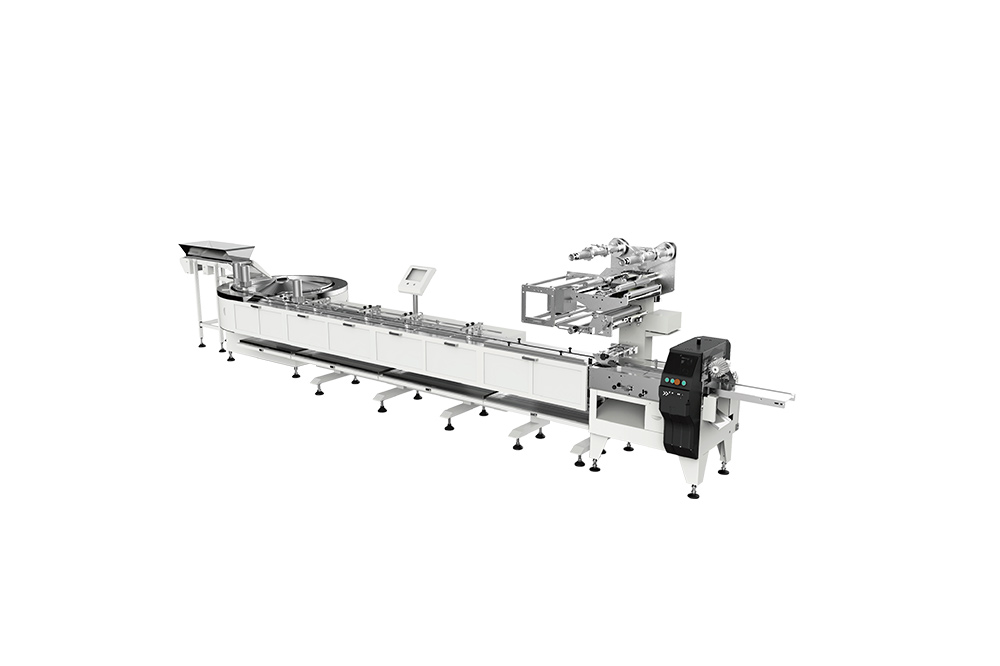

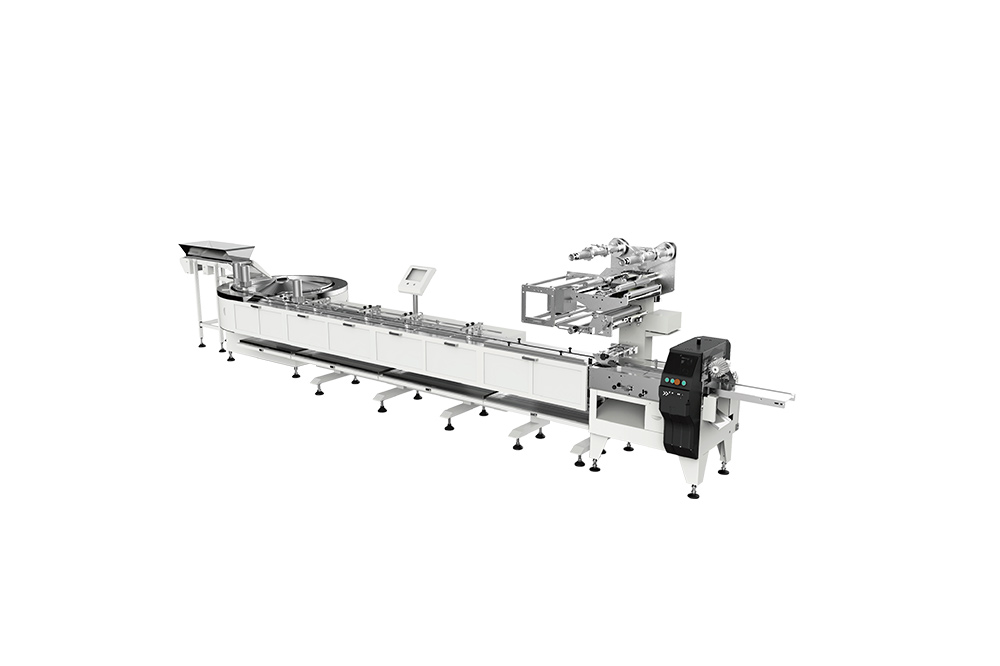

Automatic Flow Packaging Line

Candy packaging solutions are designed to protect confectionery products such as hard candies, gummies, chocolates, and lollipops from moisture, contamination, and sticking, while ensuring attractive retail presentation. Since candies vary in shape, texture, and size, packaging must provide accurate dosing, strong sealing, and visual appeal. Automated candy packaging machines support diverse formats including pillow packs, flow wraps, sachets, stand-up pouches, and cartons, covering both retail and wholesale needs.

🎥 Watch how Soontrue machines package candies in pillow packs, vertical sachets, stand-up pouches, multipacks, and cartons. Demonstrations include gummies, hard candies, and multi-flavor assortments.

The candy industry faces several challenges:

Organizing candies into multipacks or assorted packs efficiently for retail.

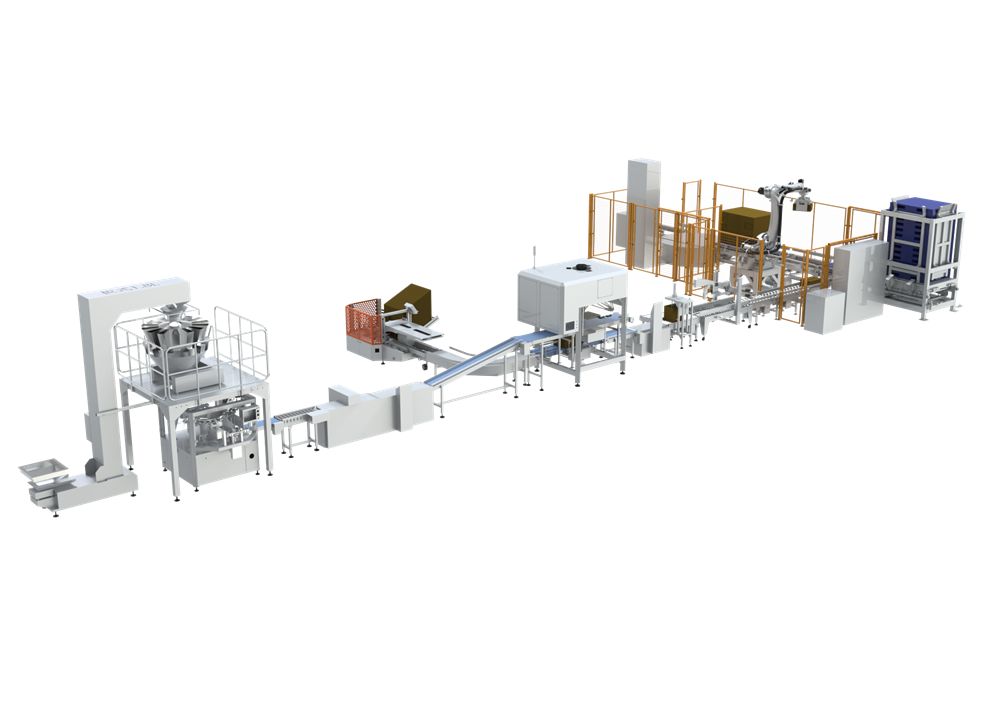

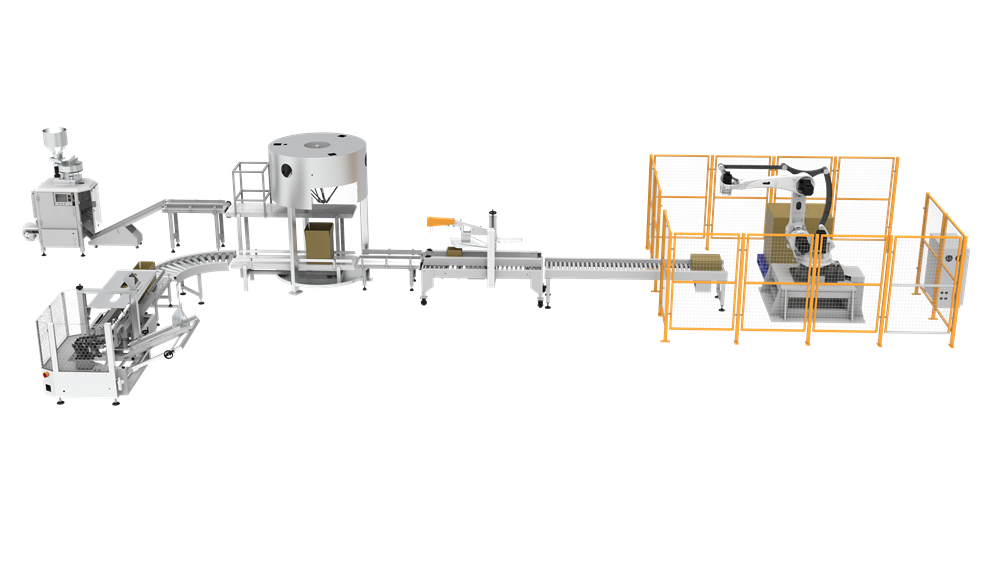

Soontrue provides complete candy packaging solutions, covering both primary and secondary packaging:

Primary Packaging

Secondary Packaging

These solutions form a fully automated candy packaging line, from individual packs to multipacks and export cartons.

Q1: What is the most common packaging style for candies?

A: Pillow packs with flow wrappers are the most common, offering speed and product protection.

Q2: Can candies be packed in resealable or premium pouches?

A: Yes. Premade pouch machines are widely used for zipper pouches and stand-up bags, ideal for premium confectionery.

Q3: How do packaging machines handle sticky or gummy candies?

A: Soontrue systems use anti-stick materials, accurate dosing, and smooth feeding systems to prevent clumping and ensure consistent packaging.

Q4: Can one packaging line handle multiple candy types?

A: Yes. With adjustable settings and modular systems, one line can pack hard candies, gummies, and assorted candy mixes.

Q5: What role does secondary packaging play in candy production?

A: Secondary packaging organizes individual candy packs into multipacks, assorted bags, or cartons, improving retail efficiency and logistics.

Soontrue provides a wide range of candy packaging machines to meet different needs:

Confectionery Packaging Machines: Flexible systems for premium pouches, multipacks, and cartons

Horizontal Flow Wrappers (SZ series): High-speed candy flow pack machines for pillow packs and multipacks.

Together, these machines create a complete candy packaging line, automating everything from single packs to multipacks and export cartons.