What Is a Packaging Machine? A Comprehensive Exploration of Its Definition, Evolution, and Role in Modern Manufacturing

Packaging Knowledge Hub

If you're seeking packaging automation solutions, please contact us, and we'll be delighted to offer you the most tailored solution.

Packaging machines have become one of the most important pillars of modern industrial manufacturing. Once regarded merely as supporting equipment, they now play a decisive role in determining production efficiency, quality stability, hygiene compliance, product safety, cost structure, labor reduction, and the market competitiveness of a factory. As global consumer demand continues to evolve and industries shift toward high-speed, high-precision, and high-hygiene production environments, packaging machinery has moved from the sidelines to the core of global manufacturing operations. In many sectors—especially food, pharmaceuticals, daily chemical products, and industrial consumables—automation is no longer optional; it is an inevitable requirement.

To fully understand why packaging machines are so essential today, it is necessary to examine what they are, where they came from, how they evolved, and why they now serve as foundational infrastructure for global manufacturing. This long-form article provides an expert-level, highly detailed, deeply integrated look into packaging machines from definition to history, from mechanisms to trends, and from industrial applications to strategic value. The goal is to enable readers—whether engineers, procurement managers, distributors, investors, or new learners—to gain a complete and practical understanding of the packaging machinery industry.

1. What Exactly Is a Packaging Machine? The Foundational Definition

A packaging machine is a highly engineered mechanical system designed to automate the processes of forming, filling, sealing, wrapping, labeling, inspecting, and preparing products for transportation, storage, distribution, and commercial sale. Its core purpose is to replace repetitive manual labor with automated, precise, controlled, and hygienic operations that ensure product consistency and protect goods from environmental, physical, and microbial risks. In essence, packaging machines convert raw or semi-finished products into stable, market-ready goods that can be safely transported, sold, and consumed.

Packaging machines perform the key functions of forming containers or bags, accurately filling products according to weight or volume, securely sealing them to prevent contamination or leakage, applying labels or batch information, inspecting quality parameters such as weight or metal contamination, and arranging the finished products for further logistics handling. Whether the machine is a horizontal flow wrapper for biscuits, a vertical form-fill-seal machine for powdered ingredients, a premade pouch packing system for coffee beans, a shrink wrapper for beverage multipacks, or a robotic case packer used at the end of the line, the fundamental purpose remains the same: to create a reliable, consistent, traceable, and hygienic packaged unit ready for distribution.

The modern packaging machine integrates mechanical engineering, materials science, electronics, automation control, servo technology, sensors, safety design, and increasingly AI-driven intelligence. Automated packaging enables factories to run faster, produce higher quality products, meet global safety regulations (such as HACCP, GMP, and FDA), reduce labor cost, and minimize waste—making packaging machines a critical element of industrial competitiveness.

2. Why Are Packaging Machines Essential to the Manufacturing Ecosystem?

Packaging machines matter because they directly influence the three most fundamental goals of industrial production: efficiency, consistency, and cost. In manual packaging, speed is limited by human fatigue, inconsistency is inevitable due to natural variations in skill or attention, and hygiene cannot be guaranteed. Modern packaging machines, in contrast, deliver high-speed, uninterrupted operation; eliminate human error; achieve precision levels measured in fractions of a gram; maintain visually uniform packaging; and comply with strict hygiene standards.

For global factories, packaging machines are crucial for reducing labor dependence—especially as many countries face rising labor costs or shortages of skilled workers. A single high-speed flow wrapper can perform the work of 10–20 manual packers while achieving significantly better consistency. Automated packaging also lowers long-term costs by reducing waste, stabilizing material consumption, minimizing product giveaway due to inaccurate dosing, and reducing the frequency of product defects.

Furthermore, packaging machines are essential for regulatory and safety compliance. In industries like food, pharmaceuticals, and medical devices, the packaging process must maintain strict hygiene, sealing integrity, and traceability standards. Machines equipped with metal detectors, vision inspection systems, leak detection units, and barcode or QR-code printing ensure that each product meets the required quality specifications before entering the supply chain.

In today’s globalized market, packaging machines serve an additional strategic purpose: they help factories meet international customer expectations. Uniform packaging, legible batch coding, tamper protection, and long shelf life are no longer luxuries—they are the minimum requirements for selling products across borders. Packaging machinery enables companies to achieve these at scale, making international expansion viable and competitive.

3. A Complete History of Packaging Machinery: From Manual Sealing to Intelligent Automation

The evolution of packaging machinery spans over 170 years, beginning with basic manual sealing tools and culminating in highly sophisticated, AI-enabled integrated systems. This historical progression reflects broader industrial transformations—from the industrial revolution to the age of electronics and today’s smart manufacturing era.

The Early Mechanical Stage (1850–1930): Birth of Packaging Mechanization

In the mid-19th century, packaging was labor-intensive and heavily reliant on manual skills. Workers folded paper bags, sealed cans by hand, corked bottles individually, and measured product quantities using manual scoops. As consumer goods markets grew and food distribution expanded, the need for higher production capacity led to the invention of simple mechanical devices such as lever-operated fillers, mechanical capping machines, and early heat-sealing tools. These devices improved consistency and reduced labor requirements, marking the first major leap in packaging technology.

The Industrial Automation Stage (1930–1980): The Rise of FFS and Flow Wrapping

The early 20th century saw the development of Form-Fill-Seal (FFS) technology, enabling the continuous conversion of roll film into formed bags, accurate filling of the product, and sealing in one integrated system. Horizontal flow wrappers (HFFS), vertical form-fill-seal machines (VFFS), and automatic labeling systems began appearing in food, confectionery, and fast-moving consumer goods factories. This era established the foundation for modern packaging automation by introducing continuous production concepts and standardizing packaging efficiency expectations.

The Electronic Control Revolution (1980–2005): Precision, Stability, and Speed

The introduction of PLC (Programmable Logic Controller), servo motors, photoelectric sensors, and HMI touchscreens reshaped the packaging industry. Machines became faster, more precise, easier to operate, and more reliable. Servo-driven motion control enabled synchronized multi-axis movement, film tracking accuracy improved significantly, sealing temperatures became controllable and stable, and machine downtime decreased due to advanced fault alarms and diagnostics. Packaging machinery transitioned from mechanically driven devices into precision automation equipment.

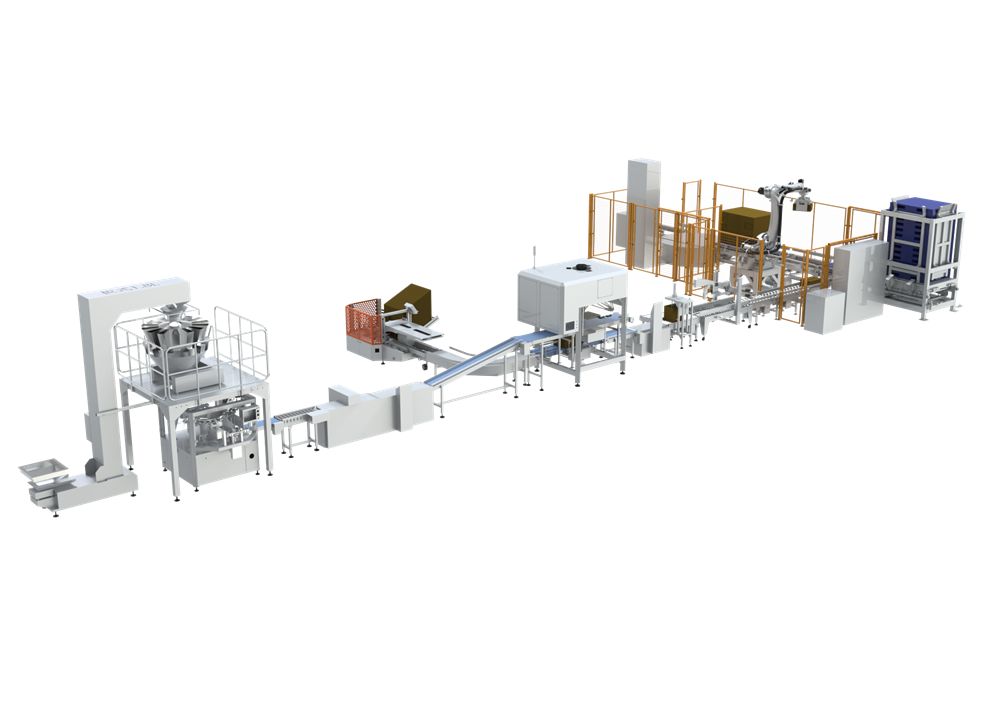

The Integrated Automation Era (2005–2020): Complete Line Solutions and Robotics

During this period, packaging machines expanded from stand-alone equipment to integrated systems. Multi-head combination weighers revolutionized high-speed weighing accuracy for snacks and granules. Robotic case packers and palletizers automated the end-of-line processes. Manufacturers increasingly demanded complete packaging solutions: infeed sorting → primary packaging → secondary packaging → case packing → palletizing → warehouse logistics. Vision inspection systems and data tracking became standard for quality assurance. Factories began migrating from segmented automation to fully connected packaging lines.

The Intelligent Packaging Era (2020–Future): AI, IoT, Digital Twin, and Unmanned Operation

The future of packaging machinery lies in intelligence. Machines are now equipped with IoT connectivity, predictive maintenance algorithms, AI-driven parameter optimization, cloud-based monitoring, digital twin simulation, and compatibility with biodegradable packaging materials. Smart systems can automatically adjust sealing temperature for different film types, detect product misplacement via AI vision systems, and alert operators before a potential failure occurs. Fully unmanned packaging lines—integrating AGV/AMR vehicles, robotic manipulators, and centralized control platforms—will become increasingly common as factories seek higher efficiency and lower labor dependence.

In summary, the packaging machine has evolved from simple mechanical tools to intelligent industrial systems capable of self-monitoring, optimization, and autonomous operation. It is one of the clearest examples of industrial transformation in modern history.

4. Types of Packaging Machinery: VFFS, Flow Wrappers & More

Although packaging machines vary widely depending on product types and industry requirements, they generally fall into several major categories. Understanding these categories gives manufacturers and engineers the ability to select the most suitable equipment for their application.

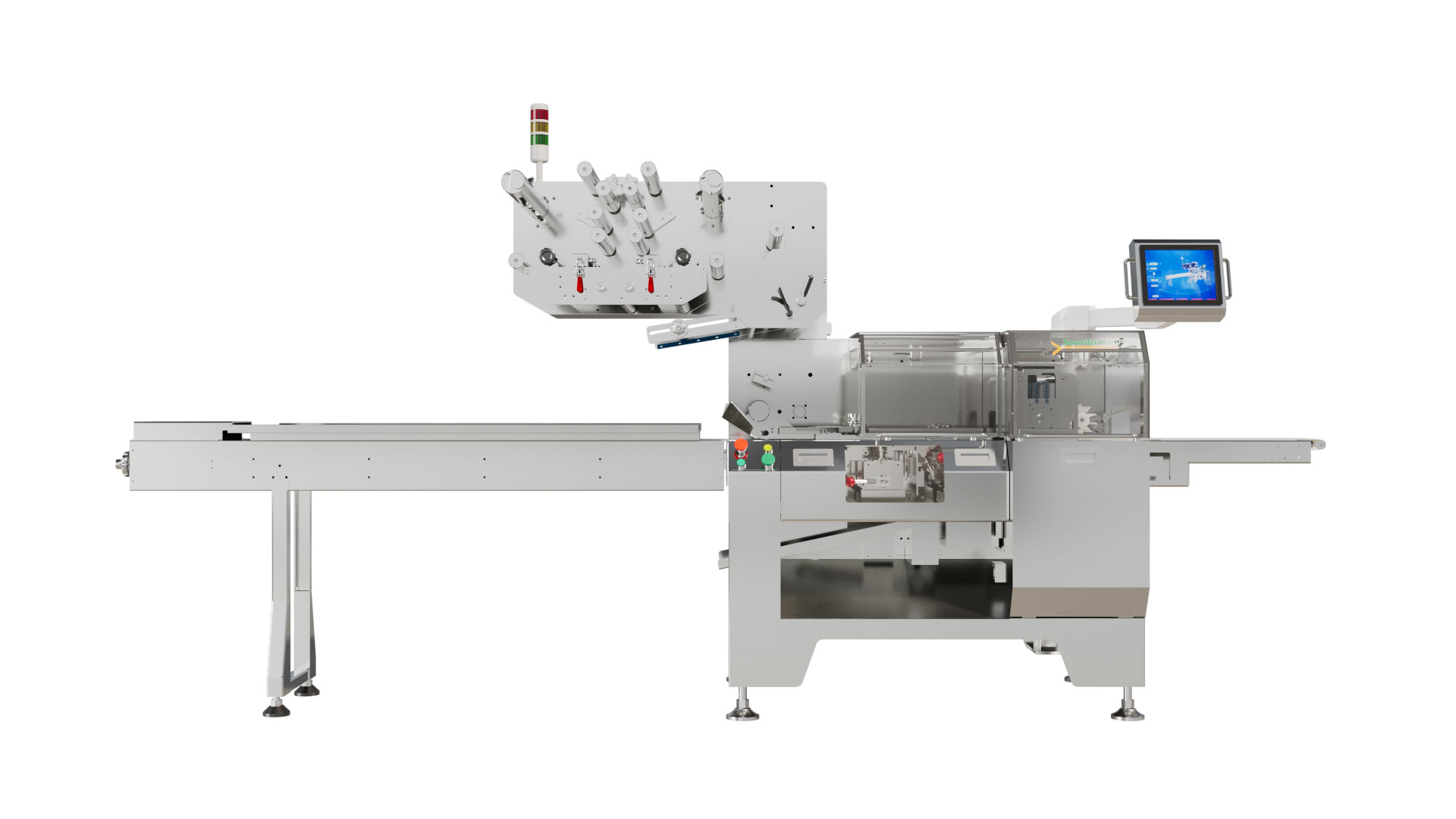

Horizontal Flow Wrapper (Pillow Packing Machine)

Horizontal flow wrappers are ideal for single-piece, regularly shaped, and high-speed products such as biscuits, bakery items, soap bars, instant noodles, and hardware components. The machine wraps products in pillow-type bags through horizontal feeding, film wrapping, horizontal sealing, and end sealing. Rotary motion models offer high-speed performance, while box-motion (reciprocating) models provide superior sealing strength and flexibility for thicker materials.

Vertical Form-Fill-Seal Machine (VFFS)

VFFS machines convert roll film into bags through vertical forming, filling, and sealing in a single continuous process. They handle granules, powder, liquid, paste, frozen items, and chemicals. Common bag types include pillow bags, gusseted bags, quad-seal bags, sachets, and stick packs. VFFS machines are highly versatile and widely used in food, chemicals, and pharmaceuticals.

Premade Pouch Packing Machine

Premade pouch machines handle stand-up pouches, zipper bags, spout pouches, flat-bottom bags, and high-grade laminated bags. They are ideal for premium products such as pet food, coffee beans, nuts, detergent powders, and liquid condiments. The machine opens the preformed pouch, fills it with a customized dosing system, seals it, and outputs the finished package with excellent shelf appeal.

Shrink Wrapping Machine

Shrink wrappers package multi-unit bundles, bottles, cans, or boxes in tight shrink film. After sealing, heat causes the film to contract and form a secure, tight-fitting package. This technology is widely used in beverage multipacks, daily product bundles, and chemical packaging.

Cartoning, Case Packing, and Palletizing Systems

Secondary packaging equipment handles product grouping, automatic box forming, case packing, carton closing, and pallet stacking. These systems complete the final stage of the packaging process before distribution. Robotic case packers handle complex arrangements, while palletizers ensure consistent stacking patterns for efficient logistics.

5. How Packaging Machines Work: A Technical Overview of the Complete Workflow

Though different packaging machines vary in structure, most share a fundamentally similar workflow. The process typically includes feeding, film transport, forming, filling, sealing, cutting, inspection, and output.

The infeed stage ensures products are arranged in the correct orientation and spacing. Film transport uses motors, belts, or vacuum systems to deliver packaging film accurately and with consistent tension. Forming devices convert the flat film into a tube or pouch shape, after which filling systems deliver precise quantities of product using volumetric, multi-head combination, auger, or pump fillers. Sealing units apply heat, pressure, or ultrasonic energy to ensure secure closure. Cutting mechanisms separate finished packs, and inspection systems verify weight, seal integrity, labeling accuracy, and product position. Finally, discharge conveyors organize finished packages for downstream processes.

Throughout the workflow, PLC and servo systems synchronize all movements, ensuring precise timing and stable performance.

6. Industrial Applications: How Packaging Machines Serve Various Sectors

Packaging machines support virtually every industry that produces physical goods.

Food & Beverage rely on packaging machines for freshness preservation, portion control, hygiene standards, and high-speed production.

Pharmaceuticals demand precision, traceability, sterility, and consistent quality.

Cosmetics & Home Care require leak-proof filling, attractive packaging, and long-term shelf stability.

Industrial & Chemical Goods need strong, durable packaging for transport safety.

Packaging machines ensure that each product reaches consumers safely, attractively, and in perfect condition.

7. Key Technologies That Define Modern Packaging Machinery

Modern packaging machines depend on multiple advanced technologies:

servo motor precision, PLC automation, HMI interfaces, sensors, vision systems, digital controls, mechanical engineering, and increasingly AI integration. Servo systems ensure high-speed accuracy, while sensors monitor film tracking, product position, sealing temperature, and potential faults. Vision systems detect misalignment, sealing defects, or missing components. Increasingly, AI plays a role in predictive maintenance, automatic parameter optimization, and quality inspection.

8. The Future of Packaging Machines

The future will be shaped by intelligent automation. AI-enabled sealing, real-time anomaly detection, digital twins for simulation, cloud-based monitoring, and fully unmanned packaging lines will become industry standards. As sustainable materials become more prevalent, packaging machines must adapt to thinner films, biodegradable substrates, and new sealing behaviors. Global factories will push toward integrated, modular, flexible packaging lines capable of handling multiple SKUs with minimal changeover time.

9. Why Soontrue Is a Global Leader in Packaging Automation

Soontrue, established in 1993, is one of China’s most influential packaging machinery manufacturers. With four major production bases and strong R&D capabilities, the company provides comprehensive solutions, including horizontal flow wrappers, vertical packaging machines, premade pouch machines, cartoning systems, case packing, robotic palletizing, and fully integrated automated packaging lines. Soontrue’s equipment is trusted globally across food, beverage, pharmaceuticals, daily chemicals, and industrial sectors due to its speed, stability, innovation, and reliable after-sales service.

10. Related Knowledge Articles

What Is a Packaging Machine? A Beginner's Guide

A clear and simple introduction to what packaging machines do and why modern factories rely on them.

Evolution Timeline of Packaging Machinery

A historical overview of how packaging technology developed through mechanical, automated, and smart eras.

Primary, Secondary & Tertiary Packaging Explained

A beginner-friendly explanation of packaging levels across the supply chain and manufacturing processes.

What Is Form-Fill-Seal (FFS)?

An introduction to FFS technology and the differences between vertical and horizontal form-fill-seal systems.

Hygiene Standards in Food & Pharmaceutical Packaging

An overview of GMP, HACCP, CE, and other hygiene requirements that influence packaging machine design.

Why Packaging Is Essential in Modern Manufacturing

Understanding the role of packaging in product protection, logistics efficiency, branding, and consumer safety.

11. FAQ

Q1: What is the purpose of a packaging machine?

A: To automate forming, filling, sealing, wrapping, labeling, and inspection processes. Its core purpose is to replace repetitive manual labor with automated, precise, controlled, and hygienic operations.

Q2: What industries require packaging machines?

A: Major industries include Food, Pharmaceuticals, Home Care, Cosmetics, Industrial Goods, and Chemicals. In these sectors, automation is no longer optional but an inevitable requirement for efficiency and hygiene.

Q3: Which machine is ideal for powder packaging?

A: A vertical form-fill-seal (VFFS) machine equipped with an auger filler is typically the ideal solution for handling powder products efficiently.

Q4: What makes packaging machines essential?

A: They improve efficiency, ensure hygiene, reduce labor costs, and maintain product consistency, which are critical elements of industrial competitiveness.

Q5: How long can packaging machines run continuously?

A: High-grade modern packaging machines are designed to operate 24/7 with minimal downtime, ensuring uninterrupted production flow.