What Types of Automated Packaging Machinery are Available? (And How to Choose)

Packaging Knowledge Hub

If you're seeking packaging automation solutions, please contact us, and we'll be delighted to offer you the most tailored solution.

In the dynamic landscape of 2025, the food manufacturing sector faces a perfect storm of challenges: escalating labor costs, unprecedented demand for product variety, stringent quality standards, and intense market competition. For food processors, agents, and distributors, navigating this environment requires more than just hard work; it demands strategic investment in efficiency and intelligence. The single most impactful lever for achieving this is packaging automation.

This comprehensive guide is designed for you—the decision-makers in the food industry. We will dissect the world of automated packaging machinery, moving systematically from a product's first contact with its packaging to its final journey on a pallet. Our goal is to provide the valuable information and solutions you need to build a resilient, efficient, and profitable operation.

What are the Fundamental Levels of Packaging?

Before diving into specific machinery, it's crucial to understand the language of packaging. A production line is organized around three distinct levels, and each level requires a different type of automation.

- Primary Packaging: This is the packaging that directly touches the food product. It's the bag holding the potato chips, the wrapper on a chocolate bar, or the pouch for a powdered soup mix. Its primary roles are to protect the product, ensure food safety, and extend shelf life.

- Secondary Packaging: This level groups multiple primary packages together. Think of a cardboard carton holding ten bags of cookies or a shrink-wrapped bundle of instant noodle packs. Its purpose is to facilitate handling, provide branding for real estate on retail shelves, and offer an additional layer of protection.

- Tertiary Packaging: Also known as transit packaging, this is the final layer used for shipping and warehousing. It involves placing multiple secondary packages (cases or cartons) onto a pallet and securing them for transport, typically with stretch film.

Understanding these levels is the first step in designing a cohesive and fully automatic packaging line.

Which Primary Packaging Machines are Essential for Food Products?

Primary packaging is where the magic happens. It’s the most critical stage for product integrity and shelf appeal. The choice of machinery here depends entirely on the product's characteristics: solid, powder, or granule.

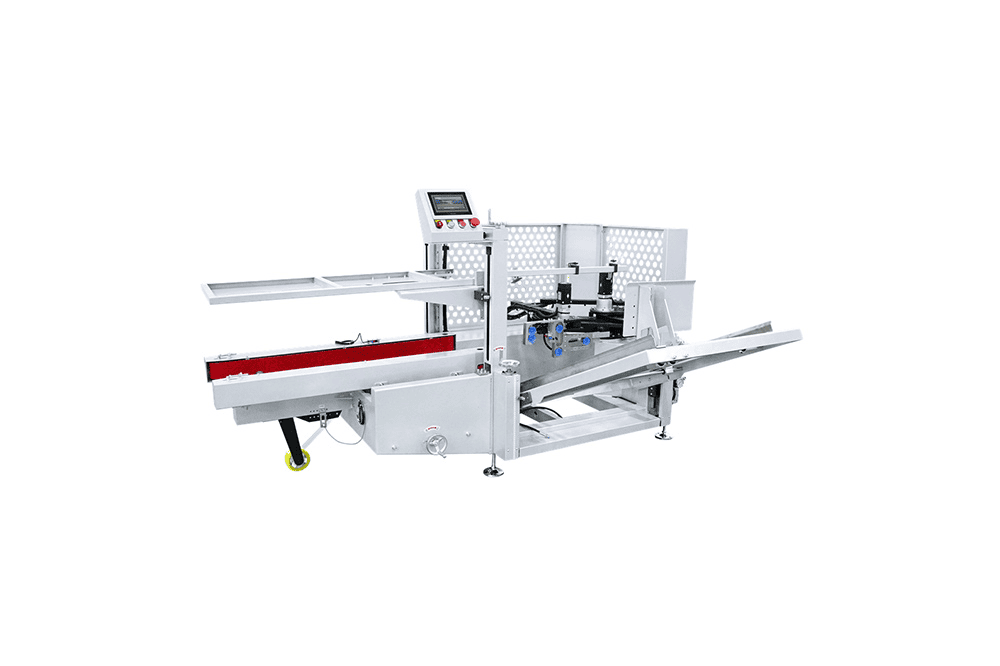

Horizontal Flow Wrappers (HFFS) Machines: The Workhorse for Solid Food Packaging

A Horizontal Form-Fill-Seal (HFFS) machine, commonly known as a flow wrapper or pillow packing machine, is indispensable for packaging solid, single-item products.

- How it Works: Products are fed horizontally along a conveyor into a tube of packaging film. The machine then seals the film longitudinally (the "fin seal") and crosswise at both ends (the "end seals") to create a sealed, pillow-shaped pack.

- Key Food Applications: Bakery goods (bread, cakes, biscuits), snack bars, chocolate bars, instant noodle blocks, frozen patties, and even grouped items like a stack of cookies.

- Why it's Essential: Flow wrappers offer high-speed operation (often exceeding 300 packs per minute), flexibility for different product sizes, and the ability to incorporate gas flushing (Modified Atmosphere Packaging - MAP) to extend the shelf life of fresh products.

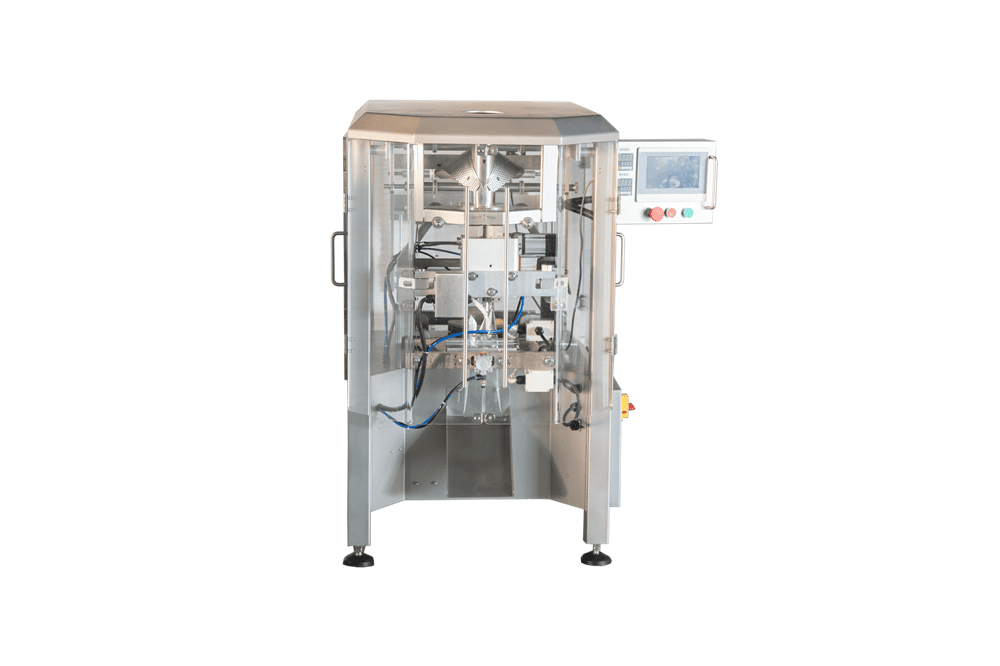

Vertical Form-Fill-Seal (VFFS) Machines: The Solution for Bulk and Granule Packaging

When dealing with products that can be dropped, the Vertical Form-Fill-Seal (VFFS) machine is the go-to solution.

- How it Works: A roll of film is formed into a vertical tube around a forming collar. The machine makes a bottom seal, and a dosing system (like a multihead weighing or auger filler) dispenses a precise amount of product into the bag. The machine then makes the top seal and cuts the bag free.

- Key Food Applications: Snack foods (potato chips, nuts, pretzels), coffee (beans or ground), sugar, spices, frozen vegetables, candy, and powders like flour or protein mix.

- Why it's Essential: VFFS systems are the heart of packaging operations for most bulk goods. When integrated with a high-precision multi-head weigher, they ensure minimal product giveaway, maximizing profitability. They can also produce a variety of bag styles, including pillow bags, gusseted bags, and quad-seal bags, to enhance on-shelf presence.

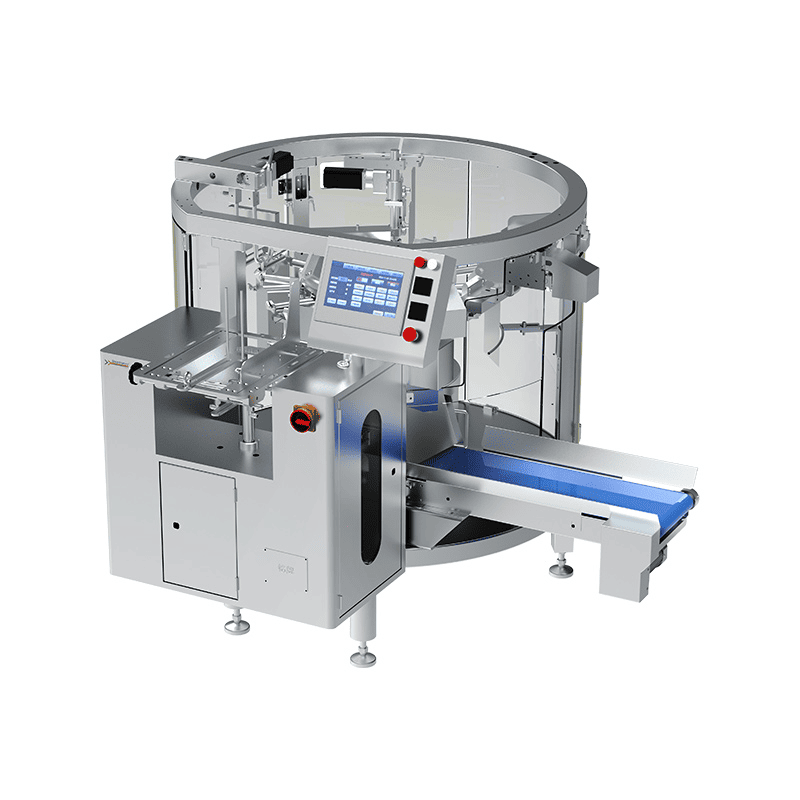

Premade Pouch Packing Machines: For Premium Shelf Appeal

For brands looking to stand out with high-quality, convenient packaging, the premade pouch packing machine is the answer. Instead of forming bags from a roll of film, this machine works with pre-made, custom-printed pouches.

- How it Works: A gripper picks a pouch from a magazine, opens it, fills it with product from a dosing system, and then seals it.

- Key Food Applications: Premium snacks, granola, pet food, sauces, ready-to-eat meals, and products requiring features like zippers or spouts. It's ideal for stand-up pouch packaging.

- Why it's Essential: While typically slower than FFS machines, pouch packers offer unparalleled flexibility in bag style and features. They can handle complex pouches (zippers, spouts, custom shapes) that are impossible to create on FFS machines, significantly boosting a product's market value and consumer convenience. They are also excellent for vacuum sealing and gas flushing applications.

Comparison of core primary packaging machinery

To help you make an informed decision between a Horizontal Flow Wrapper (HFFS), a Vertical Form-Fill-Seal (VFFS) machine, and a Premade Pouch Packing Machine, the table below provides a direct comparison across several key dimensions.

|

Feature / Criteria |

Horizontal Flow Wrapper (HFFS) |

Vertical Form-Fill-Seal (VFFS) |

Premade Pouch Packing Machine |

|

Typical Speed |

Very High (20 - 500+ packs/min) |

High (20- 120 packs/min) |

Low to Medium (≦ 80 packs/min) |

|

Flexibility (Bag Style) |

Low. Primarily pillow packs. Limited variation. |

Medium. Pillow, gusseted, quad-seal, block-bottom bags. |

Very High. Handles any premade style: stand-up, zippers, spouts, custom shapes. |

|

Initial Cost (Investment) |

Medium to High |

Medium to High (often includes a weigher) |

High |

|

Applicable Products |

Solid, single items that can be placed on a conveyor (e.g., candy bars, bread, soap, hardware). |

Loose, bulk items that can be dropped (e.g., chips, coffee, powders, frozen vegetables). |

Any product, but best for premium items where shelf appeal and convenience are key (e.g., granola, pet food, sauces). |

|

Packaging Material |

Rollstock Film |

Rollstock Film |

Pre-made Pouches |

|

Material Cost per Pack |

Low. Buying film in bulk rolls is most economical. |

Low. Same principle as HFFS. |

High. Pouches are more expensive per unit than rollstock. |

|

Footprint |

Long and narrow (due to infeed conveyor). |

Tall and compact. |

Medium, often in a rotary configuration. |

|

Key Advantage |

Maximum speed and efficiency for individual solid products. |

Best for cost-effective packaging of bulk, granular, or powdered goods. |

Unmatched shelf appeal, premium branding, and consumer convenience features. |

How Does Secondary Packaging Automation Boost Line Efficiency?

Once the product is in its primary pack, the next challenge is to group it efficiently for distribution. Manual secondary packaging is a major bottleneck and a source of labor-intensive, repetitive work. This is where secondary automation delivers a massive ROI.

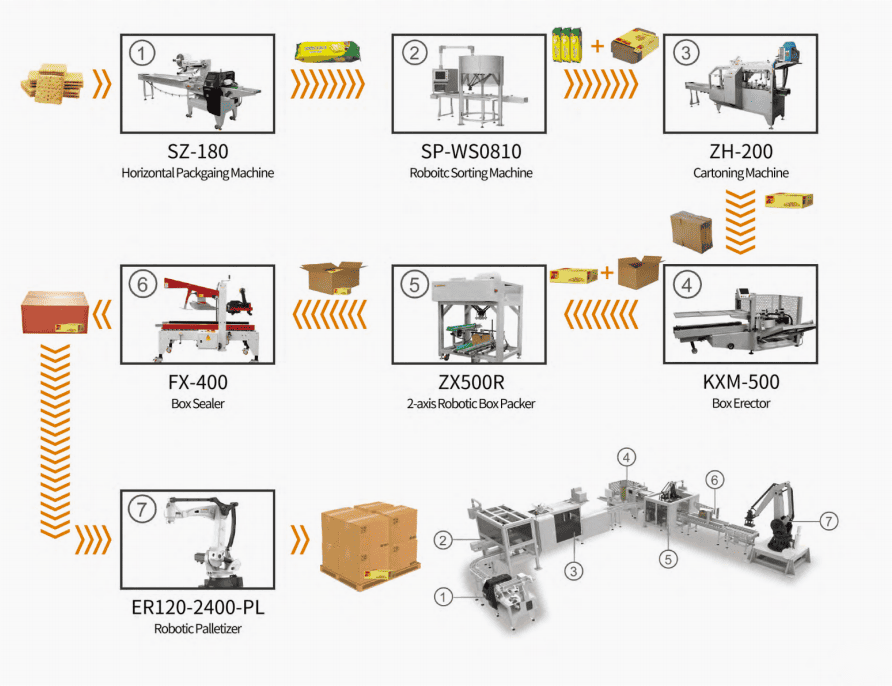

Cartoning Machines (Cartoners)

A cartoner automatically erects a folded paperboard carton, inserts the primary-packaged product (or products), and closes the ends. For a food plant making snack bars or sachets, an automatic cartoner is a game-changer, seamlessly linking the flow wrapper to the next stage.

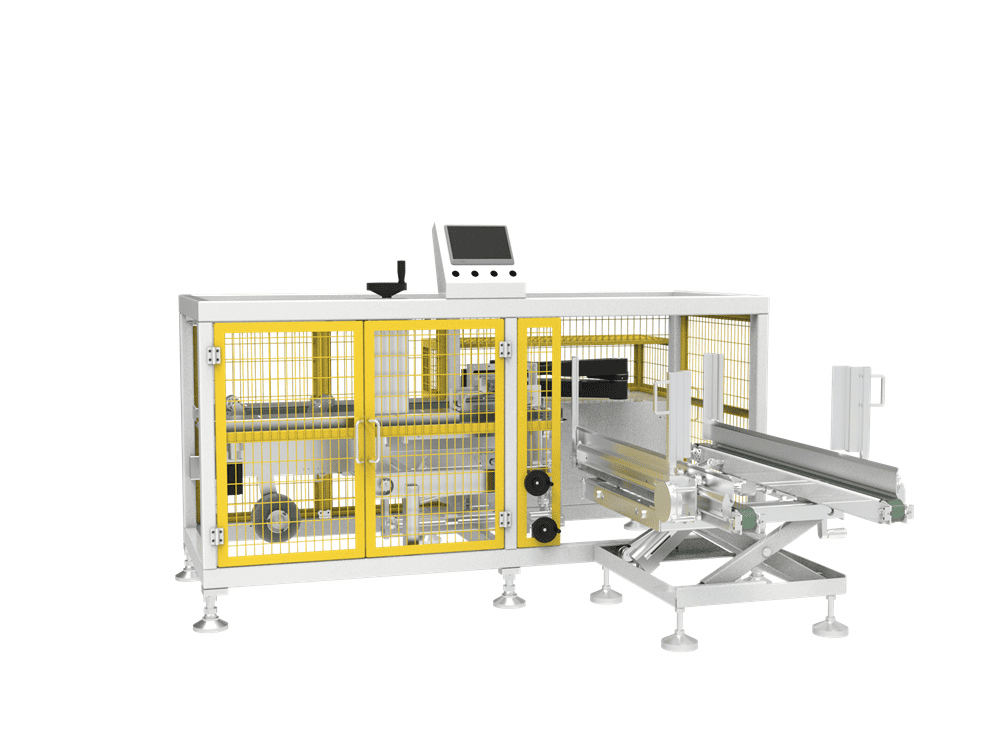

Case Packing and Sealing Systems

This is a three-part system that forms the core of secondary packaging:

- Case Erector: This machine automatically pulls a flat cardboard box, squares it up, and seals the bottom flaps with tape or hot-melt glue, presenting a ready-to-fill case to the line.

- Case Packer: This is the system that loads the products into the erected case. It can be a simple drop packer for sturdy products or a sophisticated robotic case packing system that gently picks and places flexible pouches or delicate cartons.

- Case Sealer: Once filled, the case moves to a sealer, which automatically closes and seals the top flaps, creating a shipment-ready box.

Automating this entire process can replace several workers per shift, dramatically increase throughput, and ensure consistent, perfectly packed cases every time.

What is End-of-Line Automation and Why is it Critical for Logistics?

The final 10 meters of a production line are often the most overlooked but hold immense potential for efficiency gains. End-of-line automation prepares your finished cases for warehousing and shipping, eliminating the most physically demanding jobs in the plant.

Palletizing Robots

Manually lifting and stacking heavy cases onto a pallet is slow, ergonomically hazardous, and prone to error. A palletizing robot solves all these problems.

How it Works: A robotic arm equipped with a custom gripper (end-of-arm tooling) picks up finished cases from the conveyor and precisely places them onto a pallet according to a pre-programmed pattern.

Types:

- Conventional Palletizers: High-speed systems, excellent for dedicated lines with a single product type.

- Robotic Palletizers: Highly flexible, capable of handling multiple lines, different case sizes, and complex stacking patterns simultaneously.

- Collaborative Palletizing Robots (Cobots): These are designed to work safely alongside humans without extensive safety caging. They are perfect for lower-speed applications or in plants where space is limited, offering a more accessible entry point into robotic automation.

Pallet Stretch Wrappers

Once a pallet is fully stacked, an automatic stretch wrapper uses stretch film to tightly wrap the entire load. This stabilizes the pallet for transport, protects it from dust and moisture, and provides a degree of tamper evidence. It's the final, essential step to ensure your products arrive at their destination in perfect condition.

Automation for Small Batch Producers: Starting Smart

For boutique food brands or contract packers (co-packers) handling "High-Mix, Low-Volume" orders, investing in a fully integrated, high-speed line might be overkill—and financially risky. The goal here isn't raw speed; it's flexibility.

If you are a small batch producer, you don't need to automate from A to Z immediately. Instead, adopt a Scalable Automation strategy:

- Start with Semi-Automation: Instead of a fully automatic case packer, consider a Semi-Automatic Case Sealer. An operator simply folds the box flaps and pushes it into the machine. The machine applies the tape perfectly every time. This eliminates the "bottleneck" of manual taping and ensures your boxes look professional for retail, at a fraction of the cost.

- Leverage Collaborative Robots (Cobots): As mentioned in the palletizing section, Cobots are the ultimate tool for small batches. Unlike traditional industrial robots that require safety cages and complex coding, Cobots are designed to work safely alongside humans.

- Why they fit: You can easily reprogram a Cobot to palletize a small batch of "Product A" in the morning and switch to "Product B" in the afternoon. They offer the automation you need without the rigidity of a fixed line.

The Takeaway: Don't let the fear of "big machinery" stop you. By automating just the most labor-intensive steps (like taping or palletizing) with flexible equipment, you can double your daily output without doubling your staff.

How to Choose the Right Automated Packaging Solution for Your Business?

Choosing the right machinery is a strategic decision that goes beyond just price. For distributors and agents advising clients, or for plant managers making the investment, a structured approach is key.

- Analyze Your Product: What are its physical properties? Is it fragile (biscuits), sticky (gummies), abrasive (sugar), or dusty (flour)? This dictates the type of primary packaging machine and dosing system.

- Define Your Production Goals: What is your target speed (packs per minute)? What is your daily output? Consider not just your current needs but also your growth plans for the next 3-5 years.

- Specify Your Packaging Requirements: What material will you use? Is it a standard film or a new sustainable, mono-material film that requires special sealing technology? What bag/case style do you need?

- Evaluate Your Operational Environment: How much floor space do you have? Are quick changeovers for different products a priority (flexibility)? What are the skill levels of your operators and maintenance staff?

- Calculate the Total Cost of Ownership (TCO) and ROI: Look beyond the initial purchase price. Factor in installation, training, energy consumption, maintenance costs, and spare parts. Compare this to your projected savings in labor, reduced product giveaway, increased throughput, and improved quality. A solid packaging machine ROI is often achieved in 1-3 years.

What Future Trends are Shaping Packaging Automation?

The world of packaging automation is not static. As you plan your investments, be aware of the key trends that will define the next decade.

- Flexibility and Agility: The market demands greater product variety and smaller batch sizes. Future-proof machinery must allow for rapid, tool-less changeovers to handle different products and packaging formats on the same line.

- Intelligence and Connectivity (Industry 4.0): Modern machines are becoming data hubs. They connect to factory MES/ERP systems, providing real-time data on Overall Equipment Effectiveness (OEE), tracking downtime, and enabling predictive maintenance through IoT sensors.

- Sustainability: This is no longer a buzzword; it's a business imperative. Leading packaging equipment manufacturers are designing machines that are compatible with recyclable, mono-material films and paper-based structures, which often require more precise temperature and pressure control than traditional laminates.

Your Partner in Growth: The Path Forward

Automating your packaging line is the most effective strategy to address the core challenges of modern food manufacturing. It transforms your operation from a labor-dependent cost center into a highly efficient, consistent, and scalable engine for growth.

The journey from manual processes to a fully automatic packaging line can seem complex, but it doesn't have to be. The key is to partner with an experienced and knowledgeable equipment manufacturer who understands not just the machines, but the intricacies of your industry.

Are you ready to unlock the full potential of your food processing operation? Contact our specialists today for a comprehensive line assessment. Let us help you design a tailored automated packaging solution that drives efficiency, ensures quality, and secures your competitive edge for 2026 and beyond.

FAQ

Q1: My product is solid (like an energy bar), but I want it in a stand-up pouch with a zipper. Which machine should I choose?

A: You should choose a premade pouch packing machine. While a Horizontal Flow Wrapper (HFFS) is the ideal high-speed machine for standard energy bar wrapping, it cannot create a stand-up pouch with a zipper. Only a premade pouch packer can handle this type of complex, pre-made bag to deliver the premium features and consumer convenience you're looking for.

Q2: In the long run, which is more cost-effective: a VFFS machine or a premade pouch packer?

A: It depends entirely on your business model.

The VFFS machine generally has a lower long-term operating cost because its consumable is rollstock film, which is significantly cheaper per unit than a premade pouch. For high-volume production, the savings on materials are substantial.

A premade pouch packer has higher equipment and consumable costs, but it enables a much higher product value and brand premium. If your product is positioned in a premium market where the packaging can command a higher price and market share, the investment is often justified.

Q3: I produce multiple products—some powders, some granules. Which machine offers the most flexibility for these product types?

A: For handling multiple types of flowable bulk materials, a VFFS machine offers the best combination of flexibility and efficiency. By swapping out the dosing system (e.g., an auger filler for powders, a multi-head weigher for granules), the same VFFS machine can pack a wide variety of products. While a pouch packer can also handle these, a VFFS system is typically more cost-effective and efficient for bulk goods.

Q4: Why are premade pouch packing machines generally slower than VFFS or HFFS machines?

A: The speed difference comes from their fundamental mechanics. FFS machines (both VFFS and HFFS) perform an integrated "form-fill-seal" process in a continuous or intermittent motion, which is very fast. A premade pouch packer performs a series of more complex, discrete mechanical steps: picking a pouch, opening it, checking it, filling it, and sealing it. Each step requires precise robotic movements and sensors, making the overall cycle time slower than an integrated FFS system.

Q5: Since premade pouches have a higher cost per unit, why do so many new brands choose them?

A: The primary reasons are market competition and brand positioning. In a crowded marketplace, the package is the first point of contact with the consumer. A well-designed, convenient stand-up pouch with a zipper instantly elevates a product's "perceived value" and makes it stand out on the shelf. For new or upgrading brands, this marketing advantage and improved consumer experience often outweigh the higher per-unit cost.