Choosing the Right Food Packaging Machine

Packaging Knowledge Hub

If you're seeking packaging automation solutions, please contact us, and we'll be delighted to offer you the most tailored solution.

Competition is rife in the food industry, and food producers must be efficient, safe, and aesthetically pleasing in their practices. Packaging your products is the last chance to protect the product and the first opportunity to make an impression on the consumer. Purchasing a food packaging machine that suits your needs is more than just an operational enhancement; it’s a key business choice that can affect your profits, brand perception, and ability to scale up in the market.

This post describes all the things about choosing the right food packaging machine, including types, functions, applications, and selection criteria.

What is a Food Packaging Machine?

Food packaging machine is an automated multi-function machine that can package food products through several processes, including forming, filling, sealing, wrapping, capping, and applying labels. This machinery is one of the best solutions for high-volume food packing in a hygienic way. These packaging machines automate the packaging process to deliver uniformity, reduce cross-contamination, and dramatically improve production rates.

What Are the Key Functions of Food Packaging?

Although the end result is to package a product, there are a number of vital functions of packaging that need to be accommodated by a packaging machine in the area of today’s food packaging:

Protection and preservation: The packaging should protect the food from physical (impact, vibration, crushing, or puncturing) and environmental damage(in light, moisture, and oxygen) and microbial attack.Sophisticated equipment also has high-tech features such as Modified Atmosphere Packaging (MAP) or vacuum packaging to keep freshness, color, and flavor for a longer time.

Containment and Dosing: The product is securely held and adequately dosed by the machine. From 50 g of potato chips to 1 kg of coffee beans, precision filling technology reduces giveaway, directly saving costs and guaranteeing consumer confidence.

Information and Marketing: On the retail shelf, a package itself is a “silent salesman.” Packaging machines also add labels, print date codes, and use pre-printed films that carry branding, nutrition facts, allergen warnings, and barcodes, all vital for regulatory compliance and engaging consumers.

Convenience and Handling: Packaging today is tailored for consumer convenience—easy-open tear notches, resealable zippers, and single-serve portions. The packaging machinery should be able to produce these attributes. In addition, it has high-performance options for handling, stacking, and conveying packages seamlessly from the supply chain.

Food Packaging Machine Applications and Packaged Products

The food packaging machines are highly flexible to be used for packaging different food products in different food sectors. What type of machine you need depends greatly on the physical form of your product.

Solid Products:

Snacks: Potato chips, pretzels, popcorn (VFFS machines).

Bakery: Cookies, crackers, bread (HFFS Machines).

Confectionery: Candy bars, chocolates, gummies (HFFS,VFFS pouch fillers).

Frozen Foods: Vegetables, dumplings, frozen meals (VFFS, VFFS premade pouch fillers).

Granular & Powder Products:

Granules: Coffee beans, rice, sugar, salt, nuts (VFFS with volumetric cup or multi-head weigher).

Powders: Flour, milk powder, coffee powder, spices (VFFS with auger filler).

Liquid & Paste Products:

Liquids: Juice, milk, sauces, dressings (VFFS with liquid pump, pouch fillers).

Pastes: Tomato paste, peanut butter, yogurt (Piston fillers integrated with VFFS or pouch machines).

Food Packaging Equipment Types

Packaging machines can be grouped into several broad categories, and knowing these will help you in your decision-making process.

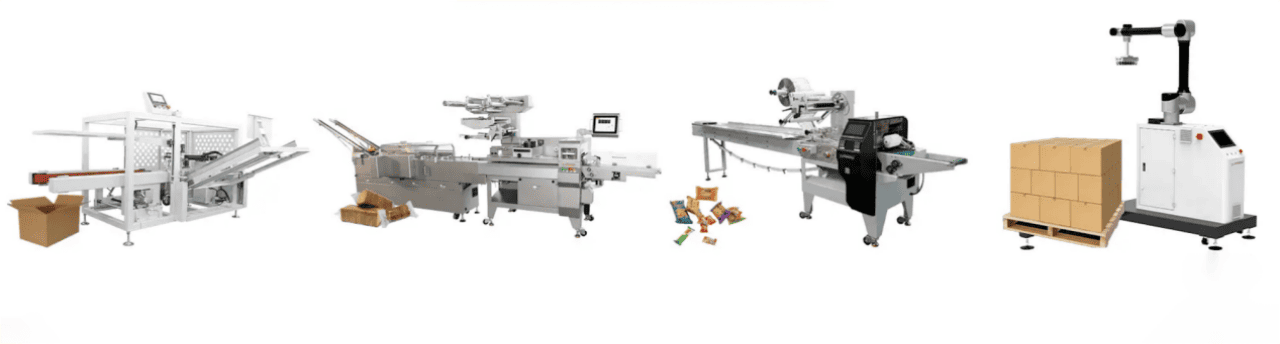

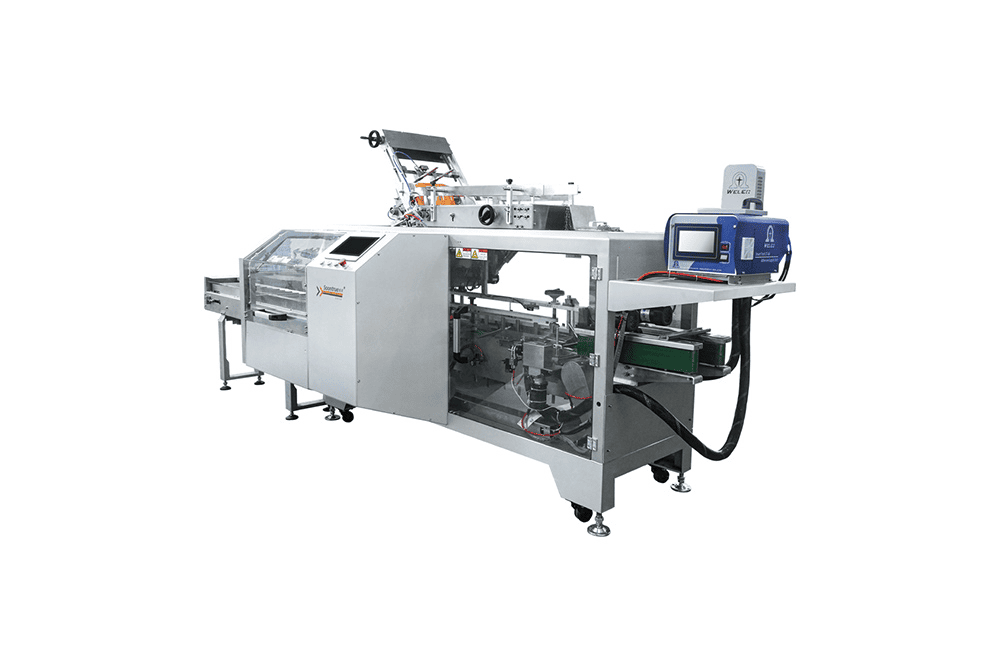

Flow Wrapping Machine

A Flow wrapping machine, also known as HFFS, is ideal for packaging solid, single-item products like candy bars, bakery items, and medical supplies into a pillow-shaped package. It offers high speed and excellent product protection.

Vertical Packing Machine

Vertical packing machines are intended for high precision, over-speed production of small handful-sized pouches. That means they are the right fit for businesses wanting to maximise efficiency and offer the same great product quality every time. Solid construction and customizable options ensure cost-effective bag filling machines that you can depend on. These are all-purpose machines that can be used to pack almost anything for a wide range of products.

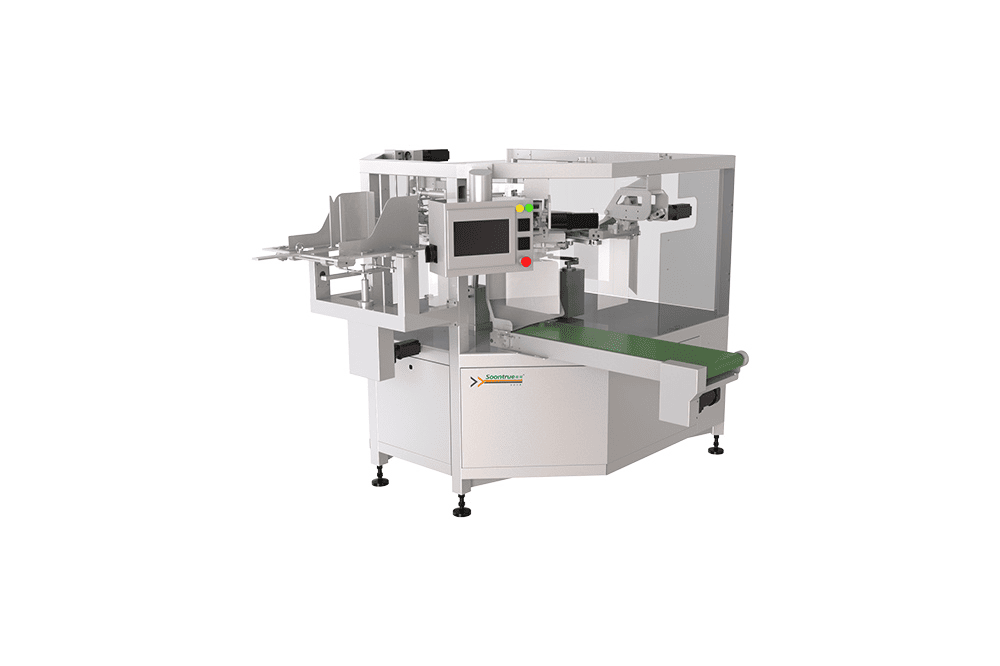

Premade Pouch Packing Machine

Premade pouch packing encompasses Rotary, Horizontal, and Bread Clipping Machines, serving a variety of industries. Rotary machines are designed for high-speed, vertical feeding of bulk products such as powders and liquids, accommodating both doypack and flat-bottom bags. Horizontal machines are perfect for fixed-shape items like frozen foods, offering airtight seals and appealing presentations. Bread Clipping Machines focus on securely closing bakery products. All machines emphasize efficiency, precision, and user-friendliness, equipped with advanced servo control systems for high-speed operation and flexibility.

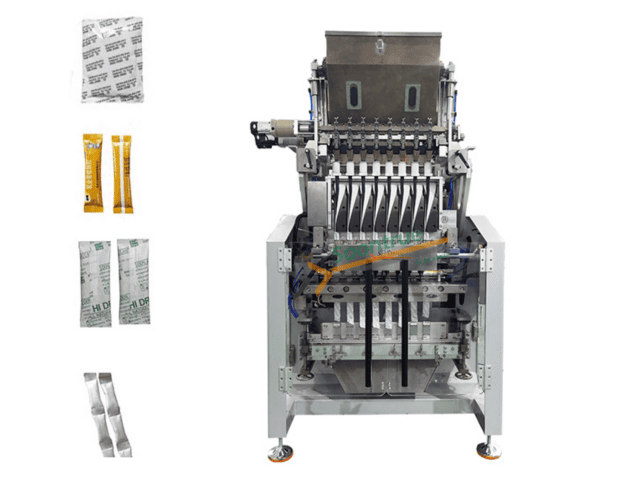

Stick Pack Packaging Machine

Stick pack packing machines produce thin, round or square, tube-like packs, which are great for single serve products, including coffee, sugar, or pharmaceutical powders. They are storage friendly and can be carried conveniently they are usually packaged in stick packs that are very common in hotels, restaurants and other public places. In addition, since less materials are used in manufacturing, they also offer cost effective package and are a good option for packaging liquids or granulated products.

Thermoformer

Thermoformers work something like this – they take a sheet of plastic and form it into containers of some shape using a mold. In fact, because of the individualized nature of the mold, thermoforming can be tailored to almost any shape and size of product.

Box Erector

Box Erector offers high performance, high speed advanced carton forming machines to improve your packaging productivity and dependability. Precision engineering and user-friendly interface, allow for reliable carton forming, increase output, and decrease costs of labor, suitable for various applicaitons in industry.

Robotic Palletizer

Robotic palletization is the process of automatically loading and unloading pallets with cases, bags, or trays, utilizing industrial robotic arms. Specialized grippers of these robots ensure that cartons, bags, boxes, or trays are consistently handled with precision. Unlike conventional palletizing machines, robot systems have better flexibility to handle different product shapes, weights, and pallet configurations.

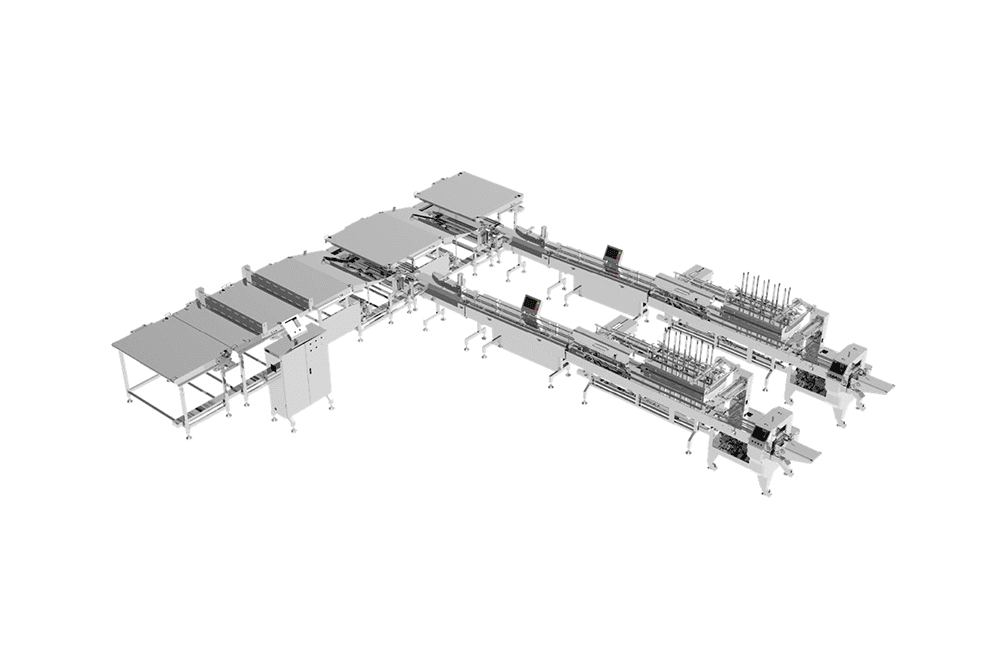

Automatic Packaging Line

Automatic packaging line is customized for food industry to improve efficiency and hygiene and less manpower. These customizable solutions can perform sorting, case packing, and palletizing to deliver high-speed output with limited human interaction. Suitable for different products, they offer a full-package solution from start to finish to help today’s manufacturers meet booming demand.

How to Choose the Right Food Packaging Machine?

Choosing the right food packaging machine is a critical strategic investment that directly impacts your production efficiency, product safety, and brand image. To help you avoid costly mistakes, we've developed this comprehensive 7-step buyer's guide. Follow this framework to make the most informed decision, step by step.

Step 1: Analyze Your Product's Nature (The Product Dictates the Machine)

This is the starting point. The physical form, characteristics, and fragility of your product will directly determine the core technology you need.

Ask yourself:

- Is your product solid and uniform? For example, cookies, bread, candy bars, or individual hardware parts.

- ➔ If yes, you should prioritize exploring [Horizontal Flow Wrappers (HFFS)], which are ideal for products that require smooth, stable handling.

- Is it a granule, powder, or irregular solid? For example, potato chips, coffee beans, sugar, milk powder, or snacks.

- ➔ If yes, a [Vertical Form Fill Seal (VFFS) Machine] is the perfect choice, as it uses gravity for efficient filling.

- Is it a liquid or paste? For example, sauces, juice, yogurt, or peanut butter.

- ➔ If yes, you will need a machine integrated with a [Liquid & Paste Filling System].

Step 2: Define Your Package Style & Material (Shelf Appeal & Practicality)

Your packaging is your "silent salesperson." What image do you want it to project on the shelf? At the same time, what functional needs must it meet?

Ask yourself:

- Which bag type do you need?

- Pillow Bag: The most common and cost-effective bag style.

- Stand-up Pouch: Offers excellent shelf presence and typically requires a [Premade Pouch Packing Machine].

- Stick Pack: Ideal for single-serve powders or liquids like instant coffee, requiring a [Stick Pack Machine].

- What packaging material will you use? Ensure your chosen machine is compatible with your film material, especially with the growing trend of recyclable or compostable films, which often have specific sealing requirements.

Step 3: Calculate Your Speed & Capacity Needs (Speed & Scalability)

Buying a machine that can't keep up with your demand—or over-investing in speed you don't need—are common mistakes.

Ask yourself:

- What is your required output in bags per minute/hour (BPM/BPH) right now?

- What is your projected business growth over the next 1-3 years?

- Pro Tip: Select a machine that meets your current demand with an additional 20-30% capacity buffer. This gives you the flexibility to handle peak orders and future growth without needing a new machine.

Step 4: Assess Your Factory Footprint & Integration (Footprint & Integration)

Even the best machine is useless if it doesn't fit in your facility or work seamlessly with your existing equipment.

Ask yourself:

- Space Dimensions: What is the available floor space (length, width, height) you have allocated? Ensure there is enough room for the machine, operators, and maintenance access.

- Integration Capability:

- Upstream: How will the machine connect to your feeding systems (e.g., bucket elevators, auger conveyors)?

- Downstream: Does it need to integrate with checkweighers, metal detectors, case packers, or palletizers?

- Control System: Can the machine's PLC communicate with your existing production line management system for full automation?

Step 5: Evaluate Budget & Return on Investment (TCO & ROI)

Professional buyers focus on "Total Cost of Ownership (TCO)," not just the initial purchase price.

Ask yourself:

- What does TCO include? Beyond the machine price, factor in: installation and commissioning fees, staff training, routine maintenance costs, spare parts, and energy consumption.

- How is ROI calculated? A reliable machine delivers a fast return on investment by:

- Reducing labor costs through automation.

- Minimizing material waste with precise filling and sealing.

- Increasing Overall Equipment Effectiveness (OEE) by minimizing downtime and maximizing productivity.

Step 6: Verify Hygiene, Safety & Compliance (Hygiene & Compliance)

In the food industry, this is non-negotiable.

Use this checklist for verification:

- [✓] Material Compliance: Are all food-contact parts made of food-grade stainless steel (e.g., SS304)?

- [✓] Ease of Cleaning: Is the machine designed for easy cleaning with no "dead spots" to prevent cross-contamination, adhering to GMP (Good Manufacturing Practice) principles?

- [✓] Safety Certifications: Does the equipment comply with the safety standards of your target market, such as CE (for Europe) or UL (for North America)?

Step 7: Choose a Trusted Manufacturer (The Partnership)

Finally, and most importantly: you are choosing a partner, not just a supplier. A great machine without reliable service is a future nightmare.

Ask yourself:

- Are they experts? Do they deeply understand your product and industry, offering expert solutions rather than just selling a standard model?

- What is their after-sales support like? What is their warranty policy, spare parts availability, and technical support response time?

- Do they have proven success stories? Can they provide customer references or case studies from your specific industry?

How to Choose a Trustworthy Packing Machine Manufacturer?

Technical Expertise & Consultation: A good supplier doubles as a consultant. They need to analyze your product and requirements on a detailed level and tell you what to use as a solution, not just push an off-the-shelf machine.

Machine Quality and Certifications: Request evidence of quality. Is the company ISO 9001 certified? Could they provide a CE certificate, please? Look for solid construction, high-quality parts (Siemens PLC, SMC pneumatics), and good finish work.

After-Sales Service and Support: If you asked me to name the most important factor, I’d say this. What are their warranty policies? Do they offer installation, training, and maintenance services? How fast can they deliver the critical spare parts? You can spend thousands if your machines are down, so dependable support is invaluable.

Customization Potential: Your product might have special needs. Your product may have some unique requirements. Can the manufacturer tailor the machine to your needs (for example, integrating a particular dosing system or a special sealing jaw)?

Reputation and Case Studies: Ask for references or case studies from companies within your industry. A good source will be eager to share their success stories and get you connected with current customers.

Food Packaging Machinery - Trends and Forecasts to 2027

The industry is continuously moving. Knowing these trends will help you keep your investment current for a long time.

Sustainability: There’s a lot of pressure to utilise recyclable or compostable packaging materials. New, modern equipment is being developed for these new green films -- films that are sometimes more difficult to seal than the traditional plastics. Efficiency in energy is an important factor in designing as well.

Automation and Industry 4.0: Smart factories are the future. Since machines have IoT (Internet of Things) Sensors for remote monitoring, predictive maintenance, and data analysis to not only track OEE but also to find ways to optimize it, with the growing availability of IoT sensors, modern machines are also expected to increasingly be compatible with those sensors.

Agility and Short Production Runs: Due to increasing variety in consumer demand, manufacturers need to produce shorter runs of more types of product (SKUs). Components that are tool-free and with quick changeovers are becoming a necessity to reduce the equipment idle time between runs.

Improved Hygiene and Cleanability: In a post-pandemic world, cleanability matters more than ever. Machines with open frame design, sloped surfaces, and minimized crevices are easier to clean and contribute to food safety.

Conclusion

Investing in the appropriate food packaging machine is a strategic choice that leads to gains in efficiency, product quality, and brand representation. You can go beyond a simple cost-based decision to a value-based decision by carefully analyzing your product, production needs, and the suppliers you might work with.

Look at the total cost of ownership, the equipment reliability, and the quality of your supplier relationship. The best machine for you is the one that not only suits your business today, but has the flexibility and scalability to grow with your business tomorrow.

FAQ

Q: How much does a food packaging machine cost?

A: Prices can range significantly, starting at a few thousand dollars for a basic tabletop sealer, and going up to more than $200,000 for a multi-head weigher and secondary packaging high-speed, fully integrated VFFS system. The end price is dependent on speed, complexity, level of automation, and what components are included. It was really important to us to think about ROI and TCO, and not just the upfront cost.

Q: How long will a food packaging machine last?

A: If well maintained and the parts that wear are regularly replaced, a good quality food packaging machine can last for two decades. Just add to that a proactive maintenance schedule and the use of genuine spare parts from the original manufacturer.

Q: Does the vendor perform installation and training?

A: From product selection to after-sales service, Soontrue provides end-to-end support. Our dedicated team offers technical training, marketing resources, and continuous guidance to ensure our distributors achieve sustained success.

Q: What is the primary application difference between a VFFS and an HFFS machine?

A: The main difference is product handling. A VFFS machine is ideal for products that may be dropped vertically through a tube into the bag, such as chips, coffee, or powders. An HFFS machine is suitable for products that must be positioned horizontally on the film, such as solids like cookies, bars of soap, or medical supplies.

Q: Can one machine accommodate a variety of product sizes and types?

A: It is quite common for this type of machine to be used for multiple products. But there are still some changes. In order to switch the product types or bag sizes, you will need to change some parts, such as a different bag former for the VFFS machine, or make some adjustments to the filler. Talk over your entire product line with the vendor to make sure the machine can be fitted for fast and simple changeover.

Q: How important is the after-sales service?

A: It's crucial. “Production downtime is enormously costly.” A vendor with great after-sales support, spare parts readily available, and good technicians who can be responsive to your needs is really a partner focused on making sure your line runs well. This should be a paramount consideration when selecting a vendor.

Q: What is the typical lead time for a new packaging machine?

A:Lead times may vary from 4 to 20 weeks based on the complexity of the machine and the lead time of the provider. Standard designs can be more rapid, while custom designs will be slower. For SZ100 and SZ180 models, lead times are typically shorter—around 2- 3 days for standard configurations—due to their modular design and high availability of components, making them ideal for quicker deployment in production lines. Organize your purchase long before you have production deadlines.