What is a Flow Wrapping Machine? A Complete Guide (2026)

HFFS Machine Blog

If you're seeking packaging automation solutions, please contact us, and we'll be delighted to offer you the most tailored solution.

In the current fast-moving market, packaging machinery is an essential tool in various industries, and particularly so in the food industry.

It is worth noting that flow packaging is the fastest growing market segment in food packaging machinery. Driven by the strong trend of increasing automation and growing demand for sustainable development, this technology is bringing unprecedented business opportunities to the baking, confectionery, snacks and processed food industries.

This post describes all the things about flow wrapping machines, their operation, advantages, applications, and materials used in packaging.

What is a Flow Wrapping Machine?

Flow wrap packaging machine is a form fill seal machine type HFFS and it packages products in a continuous motion on a flexible roll wrap film. The product travels on a horizontal plane as it develops through this machine, all the while a film is wrapped around it, and sealed on two sides to form pillow-styled package. This technology has long been the leader in food, you can be sure it’s versatile and efficient, while providing excellent product protection.

How Does Flow Packaging Machine Work?

The flow packaging has 7 main process steps as follows:

Product Feeding: The products are stacked on conveyor belts in a manual or automatic manner.

Film Formation: A continuous film roll is formed as a tube around the product through a forming box

Longitudinal Sealing: The edges of the film are sealed with heat by contacting heated sealing bars.

Cross Sealing: Individual packages are separated with transverse seals at regular intervals for a predetermined period of time

Cutting: The Cutting tool divides the sealed packets.

Quality Control: Optional vision systems check for seal integrity and the quality of the pack.

Discharge: Completed packets are delivered to an outfeed conveyor

Servo-driven means crisp positioning and excellent packaging results. Advanced models include touchscreen operation, recipe storage, and line integration for line connectivity.

Advantage of Flow Wrap Packaging Machine

Cost-Effectiveness

In the industry with intense competition and in the food industry particularly, flow wrap machines utilize the packing material to the maximum, which results in lesser wastage. Lower packaging costs are also a result of the low cost of flow wrap material.

Product Protection

Flow wrap packages wrap the product in a protective layer, which can help prevent the product from being damaged by moisture, dust, and other external influences. The flow wrap packing machine will stop the food from being contaminated and ensure food security.

Flexibility

For a wide variety of product shapes, sizes, and dimensions. Quick changeover features allow a machine to run multiple product lines, resulting in better use of the equipment.

Brand Enhancement

Films can be printed with high-quality printing for brand, nutrition, and promotional information. Some are clear, which enhances product visibility, and there is no compromise in the integrity of the package.

One of our baking clients saw a roughly 20% increase in retail visibility for their products by using custom-printed film. Such concrete examples greatly enhance credibility.

Feature Highlight: Modified Atmosphere Packaging (MAP)

For food manufacturers, extending shelf life without preservatives is a top priority. Modern flow wrapping machines often integrate Modified Atmosphere Packaging (MAP) technology, also known as gas flushing.

- How it Works: Before the film is sealed, the machine flushes the package with a specific gas mixture (typically Nitrogen or Carbon Dioxide) to displace the ambient oxygen.

- The Benefit: By removing oxygen, MAP significantly inhibits the growth of aerobic bacteria, mold, and oxidation. This keeps products like fresh baked goods, sandwiches, and processed meats fresh for days or even weeks longer than standard air-filled packaging.

- Product Integrity: Unlike vacuum packaging which compresses the product, MAP creates a protective "gas pillow" inside the pack, ensuring delicate items like croissants or soft cakes remain uncrushed and visually appealing.

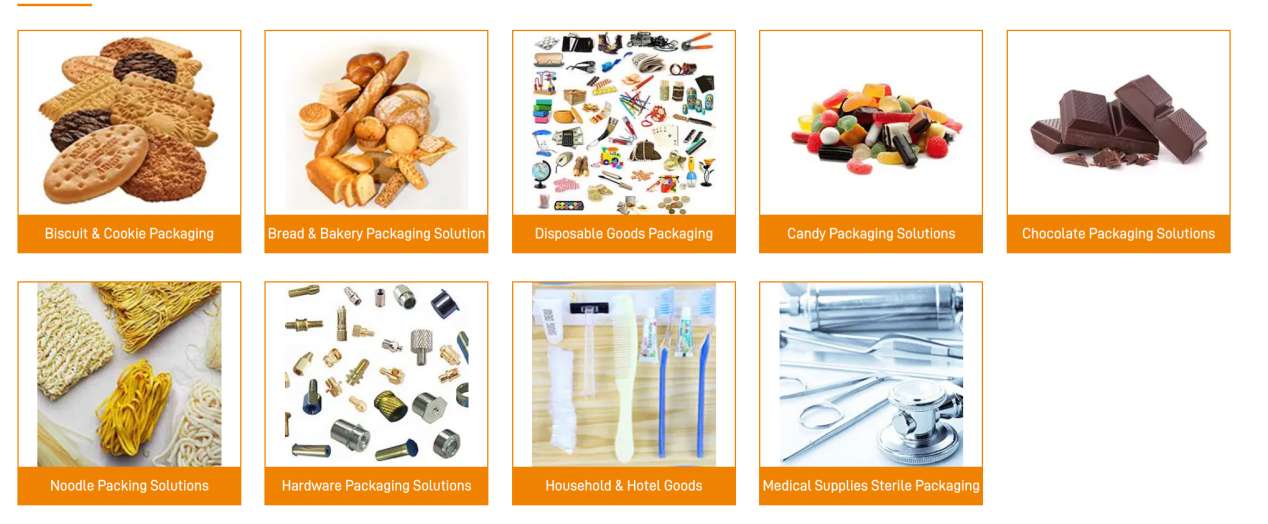

Application of Packaging Wrapping Machine

Bakery Products: Biscuits, cookies, crackers, muffins, croissants, and artisanal breads. Flow wrapping maintains freshness and presents the product well at retail.

Confectionery: Chocolate, era, chocolate chip cookies, energy bars, seasonal products , etc. Technology manages fragile goods without compromising their shape or causing damage.

Snack Foods: Granola bars, protein bars, cereal bars, snacks in individual portions. Rising healthy snacking trends boost demand in this category.

Processed foods: Sandwiches, wraps, fresh pasta, cheese portions, salad mixes. Hermetic sealing is an important prerequisite for convenience food to ensure refrigerated shelf life extension.

Frozen Applications: Single and multi-sized portions, ice cream bars, frozen veggies, center-of-plate meals. Barrier to Moisture Fix prevents freezer burn during the cold chain.

Premium markets: Dietary supplements, protein powders, meal replacement bars, functional foods that deliver enhanced barrier properties, and regulatory solutions.

Most Common Materials Used for Flow Wrapping Machine

PE Films: Polyethylene is a widely used plastic in flow wrap packaging due to its flexibility and durability. It offers excellent moisture resistance, making it ideal for food products. PE films are also recyclable, aligning with growing environmental sustainability efforts.

PP Films:Polypropylene is valued for its clarity and strength. It provides a good barrier against moisture and is resistant to chemicals, which makes it suitable for a range of products including snacks, pharmaceuticals, and hygiene products.

Heat seal films: Heat seal film is designed to form a seal when heat and pressure are applied. It’s usually a multi-layer film that has a heat-sealable outer layer, which melts and bonds to itself or to another surface to create a secure, airtight or watertight seal.

Cold Seal Films: Cold seal films are pressure-activated packaging materials with a self-sealing adhesive coating, designed to bond to themselves without heat, making them ideal for heat-sensitive products like chocolates and ice cream. This technology allows for high-speed production, a safer environment, and excellent product protection through moisture and oxygen barriers, making it a crucial innovation in food and pharmaceutical packaging

Barrier Films: Multi-layer film laminates (PE/AL/PE, BOPP/EVOH/PE). Barrier films designed to significantly slow down or block the passage of gases, moisture, aromas, light, and/or UV through the film. They help extend shelf life and protect contents from spoilage, odor transfer, or oxidation.

Green Choices: Biodegradable PLA and starch-based films provide composting solutions. Offsetting the mixed plastics with recyclable mono-materials at a 10-15% cost premium. Increasing environmental regulations necessitate the adoption.

Paper-Based Solutions: Paper/plastic laminates are attractive to environmentally conscious labels. Need exact temperature/pressure control due to thermal sensitivity, but allow for sustainable positioning in organic/artisanal markets.

What Different Types Of Flow Packing Machine?

- Basic (Starter) Machines: 50-150 packages/min, Best for small to medium businesses with minimal automation (or manual changeover).

- Intermediate Systems: 150-400 packages/min, incorporate servo-driven controls, auto film tracking, recipe storage, and touchscreen user interfaces for a more efficient operation.

- Advanced High-Speed: 400-1,500 packages/min, are equipped with vision systems, auto-changeover, Industry 4.0 connectivity, and maintenance predictability.

Flow Wrap Machines Market Outlook 2025 to 2035

According Future Market Insights : Global flow wrap machines market to reach around USD 29.9 billion in 2025 growing at ~ 3.8% CAGR to USD 43.5 billion by 2035. This is due to growing demand in food and beverage industry due to more product safety and longer shelf life, and evolving automation and green packaging technologies. Major trends to be mentioned are an increasing number of automatic machines the development of MAP (Modified Atmosphere Packaging) to prolong shelf life the use of IoT for smart monitoring.

How to Choose the Right Flow Wrapping Machine Manufacturer?

Production Analysis: Review the present volume versus the future anticipated increase. Take into account product mix requirements-multiple products worth quick changeover capacities. Test target speeds with 20-30% overflow capacity for high demands.

Product Features: The product size, weight, and fragility would influence the type of machine you use. Sticky/oily products need specialized, customized equipment. Odd shapes may require custom-formed boxes.

Quality Standards: Give preference to suppliers with certifications in the food industry (CE,FDA,HACCP). Review the quality of parts and ask for performance guarantees that include uptime.

Service Infrastructure: Check for availability of local service, 24x7 support, and spare parts availability. Integrated training for operators and maintenance personnel is mandatory.

Analysis of the aggregate costs: including installation, training, and routine operation, such as electrical consumption, maintenance, and consumables of the film, as well as the initial outlay.

Factors Influencing Flow Wrapper Prices: What Affects the Cost?

One of the most common questions from buyers is: "How much does a flow wrapping machine cost?" While prices vary widely depending on the manufacturer, the final cost is usually determined by three key technical factors:

1. Automation Level & Speed (PPM)

- Entry-Level: Basic mechanical or frequency-controlled machines (50-150 packs/min) are budget-friendly but lack precision at high speeds.

- High-Performance: Fully servo-driven (multi-axis) systems capable of 500+ packs/min command a higher price. However, they offer superior ROI through reduced film waste, faster changeovers, and lower maintenance needs.

2. Construction Material & Hygiene Standards

- Standard: Painted steel frames are cost-effective and suitable for dry environments (e.g., hardware, stationery).

- Hygienic/Washdown: For food and pharmaceutical applications, machines must be built with 304 or 316 Stainless Steel to meet FDA/GMP standards. These fully washdown-capable machines are more expensive but essential for food safety compliance.

3. Advanced Features & Peripherals

MAP Integration: Adding gas flushing systems for shelf-life extension increases the initial investment.

- Smart Systems: Features like automatic film splicing, "No Product No Bag" sensors, and AI-driven visual inspection systems will add to the total cost but significantly reduce operational labor costs in the long run.

Conclusion

Flow Wrapper is an efficient and flexible automated packaging solution widely used in industries such as food. It creates a pillow-shaped package to protect products, reduce costs, and enhance brand image. Choosing the right flow wrap machines requires a comprehensive consideration of production needs, product characteristics, supplier services, and total cost of ownership to ensure the best return on investment.

FAQ

1. What is the main difference between HFFS and VFFS?

A: The main difference lies in the product feed direction. horizontal form fill seal (HFFS) machine convey solid products (such as biscuits and chocolate bars) horizontally, while Vertical Form Fill Seal (VFFS)machine fill and package loose, granular, or liquid products (such as potato chips and coffee powder) vertically.

2. Is Flow Wrapping suitable for non-food products?

A: Yes, it is very suitable. Flow Wrapping is also widely used to package a variety of non-food products, including medical supplies (such as syringes and gauze), hardware (such as screws and small parts), daily necessities (such as soap and wipes), and stationery.

3. What is "modified atmosphere packaging" (MAP)?

A: Modified atmosphere packaging (MAP) is an advanced flow packaging technology that replaces the air inside the package with a special gas mixture (typically a mix of nitrogen, carbon dioxide, and oxygen) before sealing. This inhibits microbial growth and slows oxidation, significantly extending the shelf life of the product, especially for fresh foods.

4. How much does a flow packaging machine cost?

A: Prices range widely. Basic, entry-level machines may cost only tens of thousands of dollars, while high-end systems with integrated advanced features (such as automatic line changeovers, high-speed operation, and vision systems) can cost hundreds of thousands of dollars. The total cost should also take into account installation, training, and maintenance costs.

5. Can I use sustainable or recyclable materials for flow packaging?

A: Yes. With growing environmental awareness, a growing number of sustainable materials are available for flow packaging, including recyclable mono-material films (such as PE or PP), compostable bio-based films (such as PLA), and paper-based composites. Before selecting these materials, please confirm equipment compatibility with your machine supplier.