VFFS vs HFFS: Which Packaging Machine is Right for Your Business?

VFFS Machine Blog

If you're seeking packaging automation solutions, please contact us, and we'll be delighted to offer you the most tailored solution.

In the modern packaging industry, choosing between a horizontal form fill seal (HFFS) machine and a vertical form fill seal (VFFS) machine is a critical decision that directly impacts production efficiency and costs. The two technologies take different approaches and are suitable for different products and packaging needs. Are you struggling to decide which machine to use for your product?

Don't worry. This guide will delve into five key differences between VFFS and HFFS and provide a clear decision-making framework to help you make the wisest choice for your business.

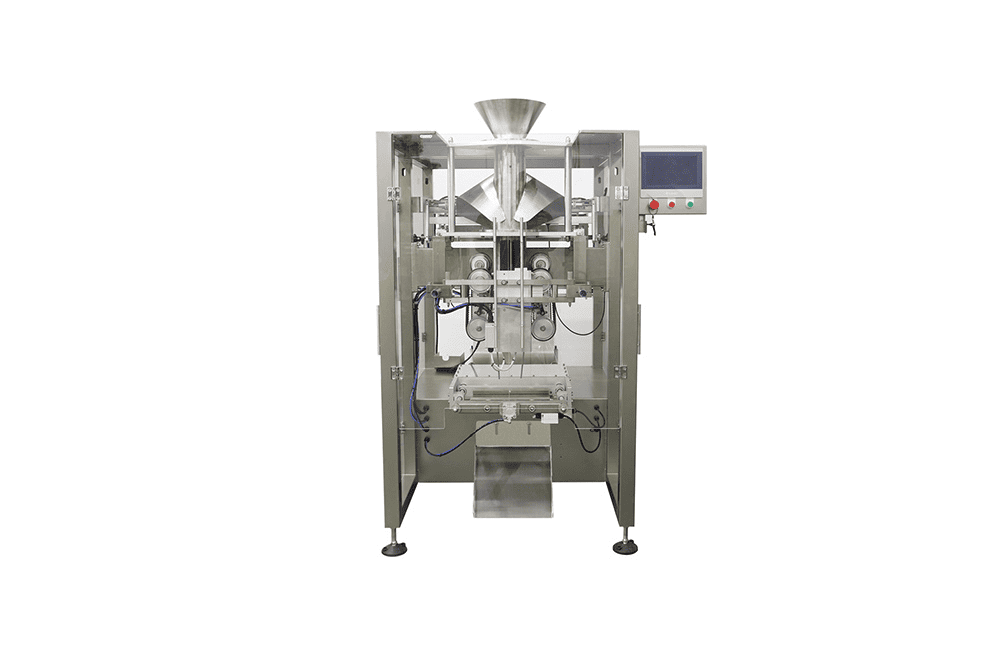

What is a VFFS Packaging Machine?

A VFFS (Vertical Form Fill Seal) packaging machine is an automated system that creates, fills, and seals bags from a roll of flexible film in a continuous vertical process. It is highly efficient and space-saving, used to package a wide variety of products like powders, granules, liquids, and solids in industries ranging from food to pharmaceuticals.

How do Vertical Form Fill Seal Machines Work?

Film Transport and Unwind: The process begins with a roll of film that is unwound and pulled through the machine by transport belts.

Film Tension Control: A dancer arm maintains proper tension on the film to prevent misalignment during movement.

Optional Printing: If equipped, printers can add necessary information such as dates or logos onto the film.

Film Positioning: Sensors ensure the film is correctly aligned for cutting and sealing.

Bag Former: The film is shaped into a tube and sealed either with a lap seal or fin seal, depending on the desired outcome.

Bag Filling and Sealing: Products are filled into the formed bags, which are then sealed using heated jaws.

Bag Discharge: Finished bags are cut and ejected from the machine, ready for further processing or packaging.

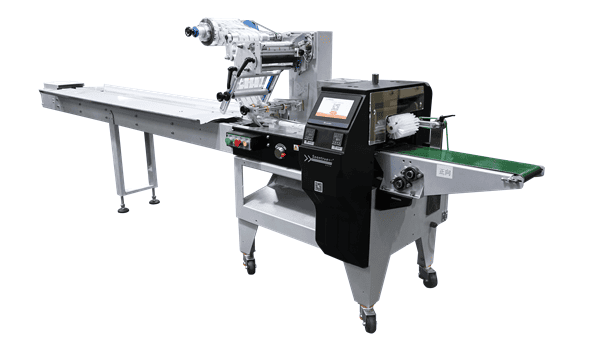

What is an HFFS Packaging Machine?

An HFFS (Horizontal Form Fill Seal) packaging machine is an automated system that horizontally forms a package from a roll of film, fills it with a product, and then seals it closed. These machines are ideal for packaging solid or single items, such as snack bars, biscuits, or chocolates, by creating a horizontal package.

How do Horizontal Form Fill Seal Machines Work?

Film Unwinding: The packaging journey begins as a roll of film is horizontally fed into the machine, ready to be transformed.

Pouch Formation: The film gracefully glides through a forming plow, meticulously folding it into a precisely shaped tube.

Product Filling: The open top of the newly formed tube eagerly awaits its contents. A filling system, tailored for either solid items, viscous liquids, or fine powders, carefully introduces the product.

Sealing and Cutting: The machine then works its magic, creating a secure and finished package. First, the longitudinal seam is sealed, followed by the bottom of the bag. Finally, the top is sealed and precisely cut, resulting in a complete and presentable package.

Package Discharge: The finished package is gently ushered out of the machine and onto a conveyor belt, ready for the next stage of its journey.

Enhanced Features: To further customize the packaging, optional stations can be integrated to add value and convenience. These include features such as date codes for traceability, a zipper for resealability, a pour spout for controlled dispensing, or a convenient notch for effortless opening.

Differences Between VFFS and HFFS Machines

By thoroughly understanding the characteristic differences between these two technologies, you will be able to select the most suitable packaging solution based on specific production requirements, product characteristics, and market positioning.

1.Machine Orientation

The most obvious difference? Orientation. The VFFS packaging machine works vertically, while the HFFS machine operates horizontally. This affects how products are fed and packaged, and it also impacts the types of products they can handle efficiently.

2.Types of Products Packaged

VFFS machines are king for bulk materials such as liquids, powders, and granules; HFFS machines are experts in solids, lumps, and individual products.

VFFS Pack:

|

Product Category |

Specific Products |

|

Granular Products |

Coffee beans, tea leaves, nuts, dried fruits |

|

Powder Products |

Flour, baking powder, protein powders |

|

Liquid and Semi-Liquid Products |

Sauces, dressings, liquid seasonings |

HFFS Pack:

|

Product Category |

Specific Products |

|

Solid Food Items |

Baked goods (cookies, crackers, nutrition bars) |

|

Irregular Shape Products |

Shaped pasta, pretzels, mixed snacks |

3.Bag Type in Vertical vs. Horizontal

VFFS & HFFS

Pillow Bag

This is the most basic and common bag type. It features a top seal, a bottom seal, and a longitudinal back seal (usually in the center of the back of the bag). Its shape resembles a pillow.

Advantages: Simple to produce, fast, and low-cost.

Applications: Potato chips, snacks, candy, ground coffee, sugar, frozen vegetables, and small hardware.

Gusseted Bag

This is a pillow bag with inward-folded "accordion edges" on both sides. This creates a more three-dimensional square or rectangular shape when filled with product, increasing internal volume.

Advantages: Provides greater capacity within limited shelf widths and allows for neater stacking.

Applications: Coffee beans, pet food, flour, rice, and laundry detergent.

VFFS Vertical Packaging Machines

Quad Seal / Block Bottom Bag

This is a more advanced bag type. It features vertical seals on all four corners and a flat bottom. The bag stands on its own without relying on the product, giving it a very sleek, premium appearance.

Advantages: Excellent shelf display, excellent stability, and a wider display area for brand information.

Applications: High-end coffee, tea, pet snacks, nuts, and cereal.

Stick Pack

A slender, small bag typically used for single-dose products.

Advantages: Portable, quantitative, and easy to tear open.

Applications:Instant coffee, milk tea powder, sugar, pharmaceutical powder, honey, and ketchup.

4.Production Speed

When packaging simple bulk materials, VFFS packaging machines are generally faster; while when handling individual products that require precise positioning, the speed of HFFS packaging machines depends on the front-end conveyor.

5.Flexibility and Changeovers

VFFS is very convenient for switching between similar products of different weights, requiring only adjustments to the metering equipment. However, changing the bag width requires replacing the entire packing machine, which is relatively time-consuming.

HFFS is generally more advantageous when switching between products of different sizes and shapes. Simply adjusting the distance between pushers on the conveyor and the width of the packaging film allows for greater product flexibility.

HFFS VS VFFS Overview :

|

Dimension |

VFFS Machine |

HFFS Machine |

|

Core Working Principle |

Product drops vertically; film is formed into a tube vertically |

Product is conveyed horizontally; film pack around it horizontally |

|

Suitable Product Forms |

Liquids, semi-liquids, powders, granules, small-sized solids |

Solids, block-shaped items, regular/irregular items, fragile goods, multi-packs |

|

Bag Type |

Pillow Bag, Gusseted Bag, Quad Seal / Block Bottom Bag, Stick Pack |

Pillow Bag, Gusseted Bag |

|

Production Speed |

Depends on the weighing tool speed and bag size |

Depends on bag size |

|

Flexibility & Changeover |

Highly adaptable to changes in product volume/weight |

Highly adaptable to changes in product shape and size |

|

Floor Space |

Smaller floor space, but may require more vertical clearance (ceiling height) |

Larger floor space, requiring significant horizontal space |

|

Typical Industries |

Snack foods, coffee, seasonings, agrochemicals, hardware |

Bakery, confectionery, frozen foods, medical devices, daily chemicals |

How to choose VFFS and HFFS for your business?

Decision Checklist: Choose Your Machine in 3 Steps

Evaluate your needs using the three steps below. Your answers will clearly point to the most suitable equipment.

Step 1: Analyze Your Product Characteristics

- Product Form: Is it a liquid, powder, or granule? ➔ Lean towards VFFS

- Product Form: Is it a solid, single item, or fragile? ➔ Lean towards HFFS

- Multi-pack Required: Do you need to package multiple items together? ➔ Lean towards HFFS

Step 2: Define Your Packaging Goals

- Shelf Presence: Do you need a stand-up bag for better shelf appeal (e.g., Quad Seal Bag)? ➔ Lean towards VFFS

- Irregular Shapes: Are you packaging irregularly shaped items? ➔ Lean towards HFFS

- Portability: Is your primary goal single-serving, portable packs (e.g., Stick Packs)? ➔ Lean towards VFFS

Step 3: Assess Your Facility & Production Line

- Space: Is your floor space limited but you have high ceilings? ➔ Lean towards VFFS

- Space: Is your ceiling height limited but you have ample horizontal space? ➔ Lean towards HFFS

- Flexibility: Do you need to frequently change over between products of different shapes and sizes? ➔ Lean towards HFFS

The decision to use HFFS vs. VFFS is not of “what’s better” but rather “what is better for us.

FAQ

1. Can VFFS and HFFS machines use the same packaging materials?

Yes, in many cases, both machines can handle similar materials like laminates or plastic films. However, the choice of material depends on the type of product being packaged and the sealing technology of each machine.

2. Which machine is more cost-effective for small businesses?

A VFFS packaging machine is generally more affordable upfront and takes up less space, making it a better option for small businesses with limited budgets.

3. How long does it take to switch between products on these machines?

Both machines can switch between products relatively quickly, but HFFS machines typically take longer due to their flexibility and custom packaging options.

4. Can either machine handle eco-friendly packaging materials?

Yes! Both vffs and hffs packaging machines can be adapted to use biodegradable and recyclable materials, depending on the manufacturer and the product requirements.

5. What is the typical lifespan of a VFFS or HFFS machine?

With proper maintenance, both vffs and hffs machines can last 10-15 years or more, making them a long-term investment for your packaging needs.