Vertical Packaging Machine Guide: Everything You Need to Know

VFFS Machine Blog

If you're seeking packaging automation solutions, please contact us, and we'll be delighted to offer you the most tailored solution.

In today's competitive food industry, packaging efficiency and flexibility have become critical factors determining business success. For food machinery dealers, distributors, and processing plant operators, understanding vertical packing machines is essential for making informed investment decisions and meeting diverse market demands.

This post describes all the things about vertical packaging machines, their operation, advantages, components, and benefits for food processing businesses.

What is a Vertical Packing Machine?

Vertical packing machines, also known as VFFS machines – vertical form fill seal, are among the most versatile and economical food packaging machines available nowadays. Such advanced machinery can convert a roll of flexible packaging film into filled and sealed pouches automatically, providing superior productivity, for enterprises large or small.

Why Manufacturers Choose Vertical packaging machine?

The packaging of food has changed considerably in the last 10 years, with consumer demands now focused on easy to use, portion controlled, and environmentally friendly High-Speed Hygienic VFFS Solutions. Vertical packing machines are the backbone of the current food packaging applications process, which processes small seasoning sachets to large bags of frozen vegetables and helps the food industry personnel to best.

Step-by-Step: How a VFFS Machine Works

The vertical form fill seal (VFFS) process transforms a flat roll of film into a finished bag in a continuous vertical motion. Here is the 6-step working principle:

Film Transport & Unwinding

The process begins with a roll of film. The machine uses motor-driven belts to pull the film off the roll smoothly, maintaining constant tension to prevent wrinkles.

Forming the Tube

The flat film travels over a forming shoulder (collar) and enters the forming tube. This step shapes the flat sheet into a hollow tubular shape.

Vertical Sealing

A heated vertical sealing bar clamps onto the overlapping edges of the film tube, creating a longitudinal seal. This forms a continuous pipe of packaging material.

Bottom Sealing

Horizontal sealing jaws close around the bottom of the tube to create the base of the bag. This simultaneously seals the top of the previous bag.

Product Filling

Once the bottom seal is secure, the dosing system (such as a multihead weigher or auger filler) drops the precise amount of product through the center of the forming tube into the open bag.

Top Sealing & Cutting

The horizontal jaws close again to seal the top of the filled bag. A cutting blade then separates the finished package from the tube, and the cycle repeats.

Key Operational Principles:

The VFFS process begins with a roll of packaging film mounted at the top of the machine. The film is drawn down over a forming tube or collar, where heat sealing creates a longitudinal seal to form a continuous tube. A horizontal sealing jaw creates the bottom seal of each package while simultaneously sealing the top of the previous package. Products are then dispensed through the forming tube into the newly created package before the next horizontal seal completes the cycle.

Advantages Over Alternative Packaging Methods:

For food industry professionals, vertical packing machines offer distinct advantages over pre-made pouch systems or horizontal form-fill-seal machines. These benefits include lower film costs (typically 20-30% less expensive than pre-made pouches), greater format flexibility, compact floor space requirements, and the ability to handle a wide variety of product types without extensive changeover procedures.

The flexibility of the technology is especially appealing to food processors with multiple products or seasonal offerings. One VFFS machine can usually package products as diverse as fine powders and chunky salsas, so it’s a suitable financial outlay for companies wishing to pack a wide range of products and get their maximum return on investment.

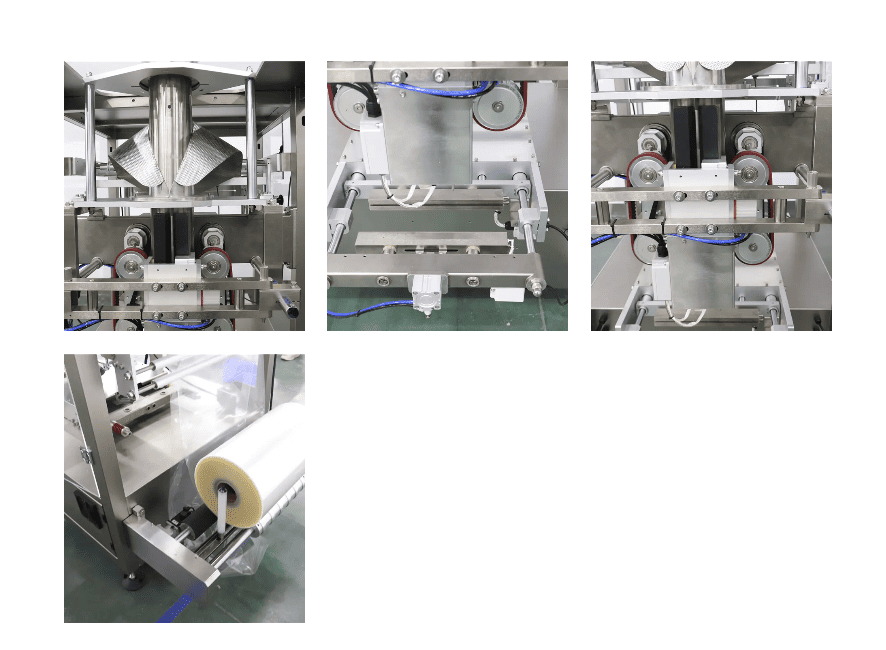

What are the basic components of a vertical packaging machine?

Understanding the basic components of vertical packaging machines is crucial for our plant operators when evaluating equipment specifications and maintenance requirements. Each component plays a vital role in ensuring consistent, high-quality packaging performance.

Film Handling System: The unwinding and film transport system manages the continuous roll of packaging material, incorporating tension control mechanisms and film tracking systems to ensure proper positioning throughout the packaging process. Advanced systems include automatic splice capabilities for continuous operation during film roll changes.

Forming System: The forming tube or collar shapes the flat film into a tubular configuration. Different diameter forming tubes accommodate various package widths, while specialized forming systems can create unique package shapes like stand-up pouches or gusseted bags. The forming system's design directly impacts package appearance and structural integrity.

Sealing System: Vertical and horizontal sealing jaws create airtight closures using controlled heat and pressure. Modern sealing systems feature temperature and pressure monitoring, ensuring consistent seal quality across varying production conditions. Some advanced systems incorporate ultrasonic or impulse sealing technologies for specific film types.

Product Dosing Integration: The machine's design accommodates various product feeding systems, with the forming tube serving as the pathway for product deposition. The integration point between the VFFS machine and dosing system is critical for maintaining package integrity and preventing product spillage.

Control System: Contemporary vertical packing machines feature sophisticated PLC-based control systems with touchscreen interfaces, providing operators with real-time monitoring capabilities, recipe storage, and diagnostic functions. These systems enable quick format changes and provide detailed production reporting essential for quality management systems.

Process Flow: The packaging cycle begins with film advancement, followed by longitudinal sealing, bottom seal creation, product dosing, and top sealing. This synchronized sequence typically operates at speeds ranging from 15 to 120 packages per minute, depending on product characteristics and package size.

Which Systems Work Best for Different Food Packaging Machine Vertical Applications?

The adaptability of vertical packaging machines is mainly due to their ability to work with different product dosing systems, allowing them to be used with almost any type of food product. For equipment suppliers and food manufacturers, it is crucial to be knowledgeable about these dosing options in order to recommend the best solutions and to make the best use of the equipment.

Multihead Weighers for Precision Applications:

Multihead weighers represent the gold standard for products requiring precise weight control, particularly in snack food applications. These systems utilize multiple weighing hoppers to achieve target weights within tight tolerances (typically ±0.5-1.0 grams), making them ideal for premium products like nuts, dried fruits, candies, and frozen foods. The combination of speed and accuracy makes multihead weighers particularly valuable for high-volume operations where portion control directly impacts profitability.

View Our Multihead VFFS Models

Volumetric Cup Systems for Consistent Filling:

For granular products with consistent density characteristics, volumetric cup fillers provide an economical solution with reliable performance. These systems excel with products like rice, beans, cereals, and pet food, where slight weight variations are acceptable. The simplicity of volumetric systems translates to lower maintenance requirements and easy operation, making them attractive for smaller processing facilities or operations with limited technical support capabilities.

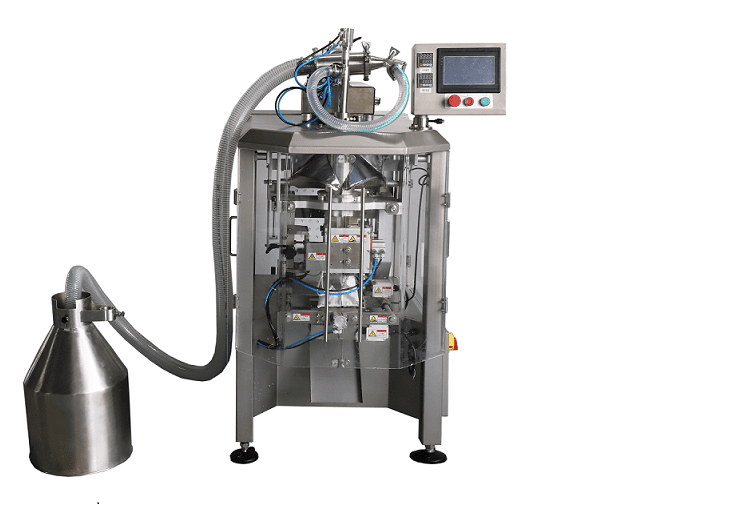

Liquid Pump Systems for Fluid Products:

The industry's growing demand for fluid packaging is evident in pump-based dosing systems. These systems handle everything from thin liquids like juices and sauces to viscous products like honey and peanut butter. Their versatility makes them ideal for both high-speed industrial lines and small vertical liquid packing machines used in boutique operations. Advanced pump systems incorporate features like anti-drip nozzles, precise volume control, and CIP (Clean-in-Place) capabilities essential for food safety compliance.

Auger Fillers for Challenging Powders:

Auger filling systems excel with fine powders that can be difficult to handle with other dosing methods. Products like flour, spice blends, protein powders, and pharmaceutical-grade supplements benefit from auger systems' ability to provide consistent, dust-free filling. The enclosed nature of auger systems also helps maintain product integrity and reduces contamination risks.

How to Choose the Right Dosing System for Your Product?

Selecting the correct dosing system for your vertical packaging machine is critical for ensuring efficiency, accuracy, and cost control. Different product characteristics—whether powder, granule, liquid, or solid—require specific technologies for optimal handling. The table below provides a clear comparison of four primary dosing systems to help you make an informed decision based on your product, accuracy needs, and budget.

| Dosing System | Core Principle | Best For | Key Advantages | Ideal Scenario |

| Multihead Weigher | Uses multiple weighing hoppers in a high-speed combination to achieve a highly precise target weight. | High-value, irregular granular or solid items:Snacks, nuts, candies, frozen foods. | Extreme Accuracy (±0.5-1.0g), high speed, minimizes product giveaway, directly impacting profitability. | High-volume production lines where precise weight control is critical. |

| Volumetric Cup | Fills packages by a set volume using standardized cups, relying on consistent product density. | Free-flowing, uniform-density granules:Rice, beans, cereals, pet food. | Economical & Cost-Effective, simple mechanics, low maintenance requirements, and easy operation. | Budget-conscious operations, smaller facilities, or where minor weight variations are acceptable. |

| Liquid Pump | Employs pumps (e.g., piston, rotary) to accurately dispense liquids and viscous products into bags. | Liquids and viscous products:Juices, sauces, honey, peanut butter. | Precise volume control, anti-drip features, and Clean-in-Place (CIP) capabilities for food safety. | Any food processing business that needs to package liquid or semi-liquid products. |

| Auger Filler | Uses a rotating screw (auger) to dispense powders in a controlled and consistent manner. | Powders and non-free-flowing powders:Flour, spice blends, protein powder, pharmaceuticals. | Consistent, dust-free filling, enclosed system maintains product integrity and reduces contamination risk. | Packaging fine, dusty, or difficult-to-handle powdered products. |

What are the benefits of a vertical packaging machine for your food processing business?

For food processing facilities evaluating packaging equipment investments, vertical packing machines deliver measurable benefits that directly impact bottom-line performance. Understanding these advantages helps plant managers justify capital expenditures and machinery dealers demonstrate value propositions to prospective clients.

Operational Efficiency and Labor Optimization: Vertical packing machines significantly reduce labor requirements compared to manual packaging operations. A single operator can typically manage production rates of 15-120 packages per minute, depending on product and package size. This automation capability is particularly valuable in today's tight labor market, where finding and retaining skilled packaging personnel presents ongoing challenges for food processors.

Material Cost Reduction: The use of roll stock film instead of pre-made pouches typically reduces packaging material costs by 20-30%. For high-volume operations, this cost differential can result in substantial annual savings. Additionally, the efficient material utilization minimizes waste, contributing to both cost reduction and sustainability goals increasingly important to food manufacturers.

Product Quality and Consistency: Automated packaging systems provide consistent package weights, seal integrity, and appearance quality that manual operations cannot match. This consistency is crucial for brand protection and regulatory compliance, particularly in applications requiring accurate nutritional labeling based on package weights. The enclosed packaging environment also reduces contamination risks and extends product shelf life.

Format Flexibility and Market Responsiveness: The ability to quickly change package sizes and formats enables food processors to respond rapidly to market opportunities and seasonal demands. Changeover times for different package sizes typically range from 15-30 minutes, allowing efficient production scheduling for multiple SKUs. This flexibility is particularly valuable for contract packaging operations serving diverse client requirements.

Integration and Scalability: Modern vertical packing machines integrate seamlessly with upstream processing equipment and downstream case packing systems, creating efficient production lines. The modular nature of VFFS systems allows for capacity expansion through additional machine installations or speed upgrades, providing scalability as businesses grow.

How Choose the Right Vertical Packing Machine for Your Needs?

Selecting the optimal vertical packing machine requires careful evaluation of multiple factors that impact both immediate operational needs and long-term business objectives. For machinery dealers and distributors, providing clients with structured selection guidance demonstrates expertise and builds confidence in equipment recommendations.

Production Requirements Assessment: The foundation of equipment selection begins with accurately assessing production volume requirements, both current and projected. Consider peak production demands, seasonal variations, and growth projections over the equipment's expected lifespan. Undersized equipment constrains growth potential, while oversized systems may never achieve optimal efficiency levels.

Product Characteristics and Compatibility: Different products present unique packaging challenges that influence equipment selection. Free-flowing granular products offer the greatest flexibility, while sticky or fragile products may require specialized handling features. Evaluate product temperature, moisture content, particle size distribution, and any special handling requirements that might necessitate specific machine configurations.

Package Format and Market Requirements: Consumer preferences and market positioning influence package size, shape, and film requirements. Consider whether applications require barrier films for extended shelf life, promotional printing capabilities, or specialized closures like zippers or tear notches. The machine's ability to accommodate future package format requirements should factor into selection decisions.

Integration and Infrastructure Considerations: Evaluate existing facility infrastructure, including available floor space, utilities (compressed air, electrical, and steam requirements), and integration points with existing production equipment. Consider maintenance access requirements and the availability of trained personnel or service support in your geographic area.

Total Cost of Ownership Analysis: Beyond the initial capital investment, evaluate ongoing operational costs including energy consumption, maintenance requirements, spare parts availability, and training needs. Consider the supplier's reputation for reliability, technical support quality, and the availability of upgrade paths as technology evolves.

Why Are Vertical Packing Machines the Future of Food Packaging?

Vertical packing machines represent a cornerstone technology for modern food processing operations, offering the flexibility, efficiency, and reliability necessary to compete in today's dynamic marketplace. For machinery dealers, distributors, and food processors, these systems provide a pathway to operational excellence and sustainable growth.

The technology's proven track record, combined with ongoing innovations in control systems, material handling, and integration capabilities, ensures that vertical packing machines will continue to play a vital role in food industry packaging solutions for years to come.

FAQ

Q1: What is the maximum packaging speed of a vertical packaging machine?

A: The packaging speed of a vertical packaging machine ranges widely, from 15 to 120 bags per minute, depending on product characteristics, package size, and machine configuration.

Q2: How long does it take to change to a different bag size?

A: The format changeover time for a modern vertical packaging machine typically ranges from 15 to 30 minutes, depending primarily on the package size and operator proficiency. A typical size changeover involves replacing the forming tube, adjusting the seal position, and resetting control parameters.

Q3: What are the special requirements for packaging film in a vertical packaging machine?

A: Vertical packaging machines use roll-to-roll film, which reduces costs by 20-30% compared to pre-made bags. The film must have good heat-sealing properties, appropriate stiffness, and tensile strength. Common materials include PE, PP, and PET composite films. Standard or high-barrier films can be selected based on product characteristics. For food applications, the film must also meet food safety standards. Film widths typically range from 100-620mm, with thicknesses of 50-150 microns.

Q4: Is maintenance of a vffs machine complex?

A: Daily maintenance for a vffs machine is relatively simple, primarily consisting of cleaning, lubrication, and basic adjustments. Operators can perform most routine maintenance tasks after training. Key maintenance tasks include cleaning the sealing system, lubricating drive components, and calibrating temperature controls. A regular maintenance schedule is recommended: daily cleaning and inspection, weekly in-depth maintenance, and monthly professional inspections.

Q5: How do you evaluate the return on investment (ROI) of a vertical packaging machine?

A: ROI evaluation requires considering multiple factors: equipment investment cost, packaging material savings, reduced labor costs, and the benefits of increased productivity and quality improvements. Generally, Soonture's vertical packaging machine can produce more than 80 packages per minute and more than 4,800 packages per hour. For food processing companies, investment is most suitable in environments with relatively concentrated product lines, relatively standardized packaging specifications, high requirements for consistent packaging quality, and rising labor costs. Generally, the payback period is between 12 and 24 months, depending on production scale and product characteristics.

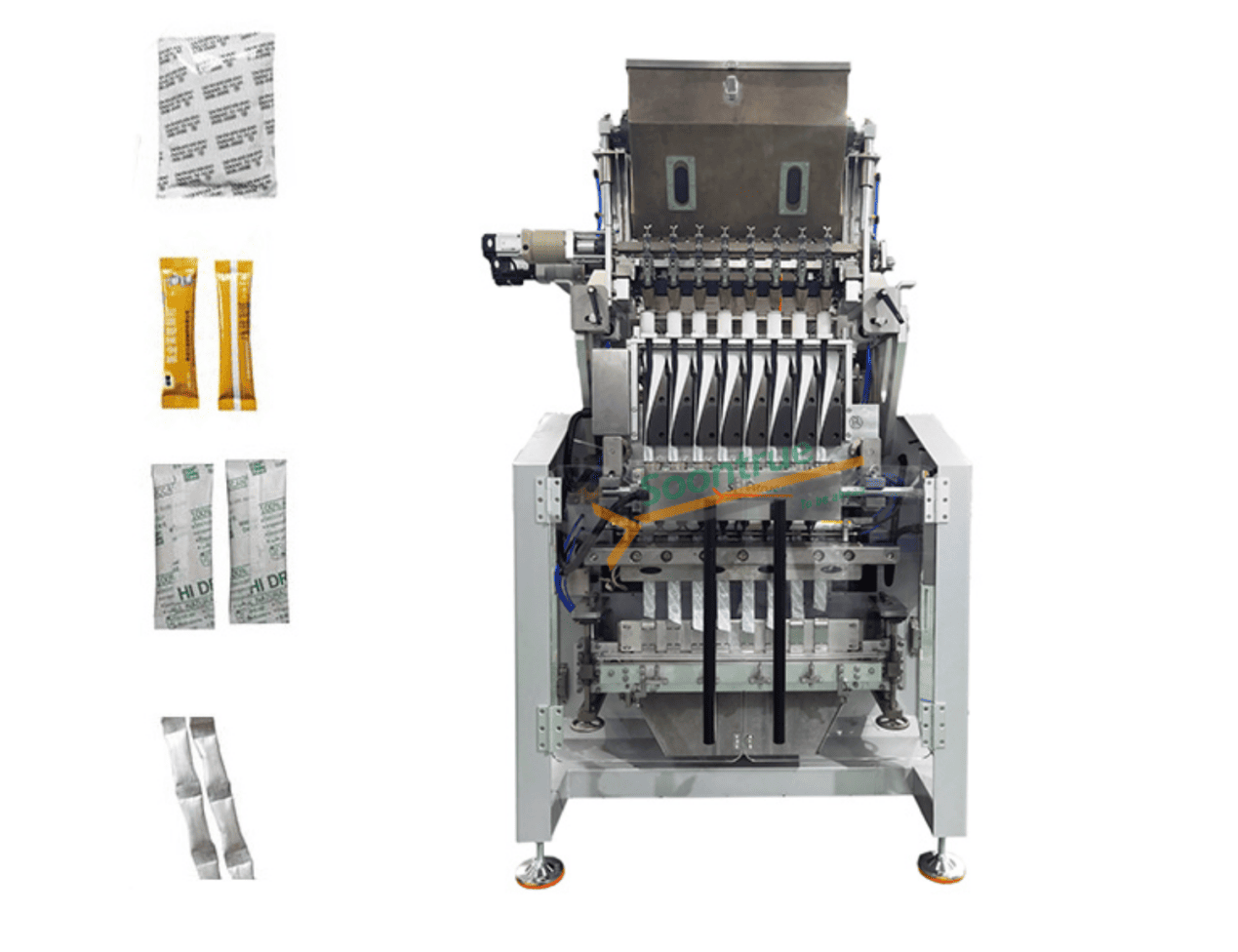

Q5:What are the types of bags for the VFFS machine?

A: The types of bags compatible with VFFS machines depend on the machine's design, product type, and desired packaging style. The five primary VFFS bag types—Pillow Bags, Gusseted Bags, 3 Side Seal Bags,Block Bottom Bags, and Stick Packs