AIS-200 Robotic Box Erecting Machine

AIS-200 Robotic Box Erecting Machine Typical Applications

- Food & Beverage: carton forming for packaged snacks, bakery, and dairy products

- Pharmaceuticals & Healthcare: precise and hygienic carton erection for medical supplies

- Daily Necessities: suitable for personal care items, household goods, and disposables

- Electronics & Hardware: packaging support for appliances, spare parts, and industrial goods

- E-commerce & Logistics: carton forming for shipping and fulfillment centers

The AIS-200 is an advanced robotic box erecting machine designed to automate carton forming with high speed and precision. Unlike traditional semi-automatic systems, the AIS-200 utilizes robotic arms and servo-driven control to achieve fast, consistent, and accurate box erection, ensuring every carton is perfectly shaped for downstream packaging processes.

Engineered for high-volume production environments, the AIS-200 significantly reduces labor dependency and minimizes human error. Its intelligent control system allows for quick carton size adjustments, supporting a wide range of carton dimensions, making it ideal for industries with diverse packaging requirements.

By integrating robotics with automation, the AIS-200 not only improves efficiency but also enhances safety, reliability, and long-term cost savings in end-of-line packaging operations.

Machine Parameters

| Specifications | AIS-200 | AIM-400 | AIL-500 |

| Box size range | L 130-300 mm | L 200-500 mm | L 200-650 mm |

| W 90-220 mm | W 170-400 mm | W 170-500 mm | |

| H 90-220 mm | H 250-600 mm | H 250-750 mm | |

| Erecting speed | 5-25 boxes/min | 5-20 Boxes/min | 5-20 boxes/min |

| General power | 2.1 Kw | 2.8 Kw | 2.1 Kw |

| Remark |

Box L+W ≤ 460 mm Box H+1/2W ≤ 320 mm |

Box L+W ≤ 900 mm |

Box L+W ≤ 1150 mm

|

| Power supply | 220V/1Ph/50Hz | 220V/1Ph/50Hz | 220V/1Ph/50Hz |

| Machine weight | 440 kg | 960kg | 1075kg |

| Machine dimensions | 1880x2091x1179 mm | 2775x2645x1350 mm | 3351x3182x1570 mm |

| Adhesive tape |

W50mm or below |

W60mm or below | W50mm or below |

📌 Reference: Internal test data by Soontrue R&D Lab (2024)

Key Features

- Versatile Box Compatibility: The AIS-200 can handle a variety of box sizes, including square and rectangular cartons, as long as they fall within the specified range.

- Thin Box Adaptability: The machine is optimized to work with thinner cartons, making it a flexible solution for different packaging requirements.

- Pre-cut Carton Compatibility: Cartons must be pre-cut with crease lines before feeding into the machine for smooth operation.

- Smart Positioning System: Utilizes independent servo motors for carton extraction and handling, ensuring high precision and minimal misalignment.

- Fully Automated Operation: Pneumatic-driven bottom-flap opening mechanism allows for smooth and efficient carton forming without damaging the materials.

- Customizable Settings: Adjustable box parameters allow users to optimize the machine based on different carton specifications.

- Compact Footprint: The AIS-200 is designed to occupy minimal space while maintaining high-speed performance.

- Safety Features: Equipped with safety doors and emergency stop functions to ensure operator security.

- European Standard Wiring: Electrical terminal design and wiring layout conform to European safety regulations.

- High-Speed Box Magazine: The machine allows for automatic height adjustment of the box storage, reducing manual intervention.

- Dual Suction Plate Opening System: The long-edge-to-long-edge opening system accommodates thin and thick cartons effectively.

- Heavy-Duty Construction: The robust frame ensures smooth operation with minimal vibration, improving stability.

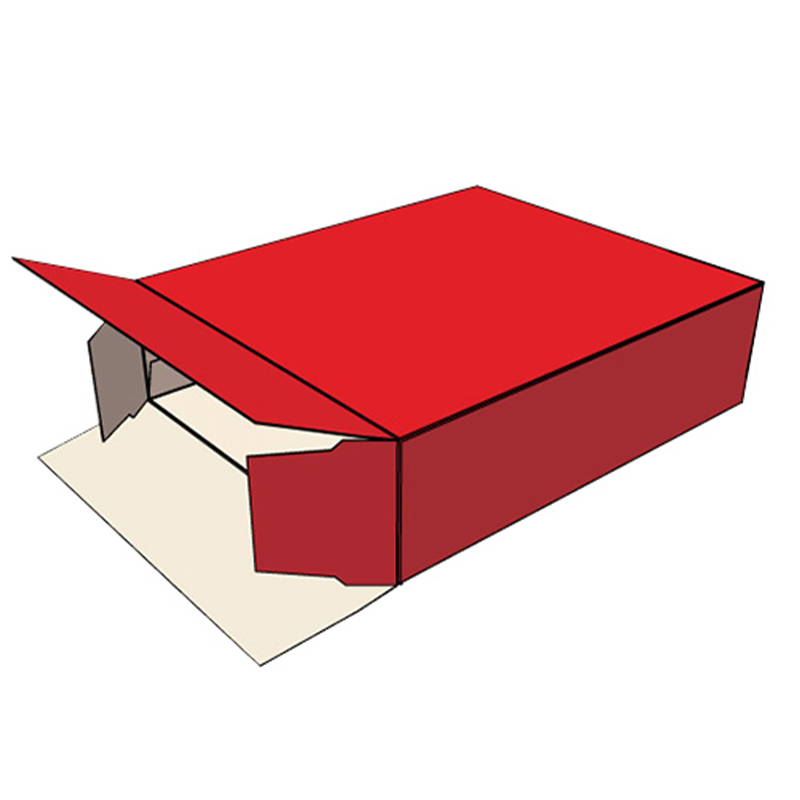

Bag Type

Competitive Advantage

Compared to conventional box erecting machines, the AIS-200 offers a robotics-driven forming system that ensures higher precision, reduced downtime, and better consistency. While many competitor machines require frequent manual adjustments, the AIS-200 minimizes operator intervention and supports quick size changeovers. Buyers benefit from lower labor costs, faster ROI, and higher throughput, making it more competitive in demanding production environments.

Why Choose Soontrue?

With over 30 years of experience in packaging automation, Soontrue provides innovative, reliable, and efficient solutions across industries. The AIS-200 reflects Soontrue’s commitment to combining robotics and automation to meet modern end-of-line packaging needs. Backed by a global service network and strong R&D, Soontrue ensures long-term performance, timely support, and adaptability as your business scales.

FAQ - AIS-200 Robotic Box Erecting Machine

Q1: What types of cartons can the AIS-200 handle?

It is compatible with a wide range of corrugated cartons, supporting multiple sizes for food, daily goods, and industrial packaging.

Q2: How does the robotic system improve efficiency?

The robotic arm ensures precise pick-up and folding, reducing misformed cartons and enhancing consistency at high speeds.

Q3: What is the average speed of the AIS-200?

It can erect up to 1500 cartons per hour, depending on carton size and material quality.

Q4: How easy is it to switch carton sizes?

The servo-driven system and intelligent control panel enable quick changeovers with minimal downtime.

Q5: Is the AIS-200 suitable for integration with other machines?

Yes. It is designed for seamless integration with cartoning, case packing, sealing, and palletizing systems in automated packaging lines.