Why Upgrade to a Servo-Driven Pillow Packing Machine?

HFFS Machine Blog

If you're seeking packaging automation solutions, please contact us, and we'll be delighted to offer you the most tailored solution.

In the competitive landscape of food manufacturing and distribution, the margin between profit and loss is often measured in milliseconds and millimeters. For food processing factories and machinery distributors, the equipment on the floor defines production capability.

While traditional mechanical packaging machines have served the industry for decades, the market has shifted. Rising raw material costs, labor shortages, and the demand for diverse SKU production have made Automatic packaging efficiency the new gold standard.

This guide explores why the servo-driven pillow packing machine is no longer just a luxury option—it is the strategic investment required to future-proof your production line.

What is a Servo-Driven Pillow Packing Machine?

To understand the value, we must first understand the technology. A traditional pillow packing machine (or flow wrapper) typically relies on a single AC motor connected to a complex system of chains, gears, and mechanical cams to coordinate movement. If you want to change the bag length, you often have to physically adjust a handwheel or change a gear.

A servo-driven pillow packing machine replaces this mechanical rigidity with digital intelligence.

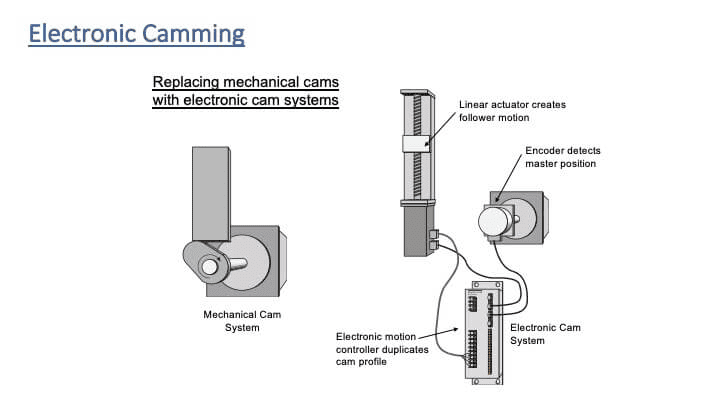

How Packaging Servo Motors & Electronic Cams Work

Instead of physical gears, servo machines use a motion controller (PLC) to synchronize multiple independent motors. This is often referred to as "Electronic Cam" technology. The machine’s "brain" calculates the position of the film, the product, and the cutter in real-time, making micro-adjustments thousands of times per second.

The Full Servo Driven System

Most high-end pillow packing machines feature a 3-servo control system. This is crucial for distributors explaining the machine's value to end-users:

Servo 1: Infeed Conveyor: Controls the speed at which products enter the film tube.

Servo 2: Film Drive: Controls the tension and speed of the film pulling.

Servo 3: End Seal/Cutter: Controls the rotation of the sealing jaws.

Because these three servo motors are independent yet perfectly synchronized digitally, you can adjust one without disrupting the others. This architecture is the foundation of modern Automatic packaging efficiency.

The "High-Speed Flow Wrapper" Advantage

Speed is the most common metric used to sell machinery, but for food factories, stable speed is what matters. A mechanical machine might claim 200 packs per minute, but at that speed, the vibration often causes seal leaks or product damage.

A High-speed flow wrapper equipped with servo motors operates differently.

Smooth Acceleration and Deceleration

Servo motors provide programmable acceleration and deceleration curves. Unlike a mechanical clutch that engages with a "jolt," a servo motor ramps up speed smoothly.

- For Fragile Foods: If you are packaging biscuits, crackers, or chocolate bars, this smooth motion prevents breakage during the start-stop cycles.

- Vibration Reduction: By eliminating heavy chains and mechanical cams, the machine runs quieter and with significantly less vibration. This extends the lifespan of the equipment and ensures consistent seal quality even at speeds exceeding 300 packs per minute.

Precise Seal Integrity

In the food industry, a leaking seal equals a recalled product. Servo control ensures that the end seal jaws meet at the exact millisecond required, applying consistent pressure and dwell time regardless of the machine's running speed. This guarantees airtight seals for nitrogen-flushed (MAP) applications, extending shelf life.

Smart Features That Define Automatic Packaging Efficiency

For machinery agents and distributors, selling a machine is easier when you can demonstrate tangible cost savings. The intelligence of a servo-driven pillow packing machine unlocks features that mechanical machines simply cannot offer.

1. "No Product & Packaging"

This is the single biggest ROI factor for factories. Sensors on the infeed conveyor detect if a product is missing from a slot.

- Mechanical Machine: Will wrap an empty package, wasting film and requiring labor to sort it out later.

- Servo Machine: The film drive and cutter automatically pause and wait for the next product.

- The Impact: If a factory runs at 200 ppm and has a 1% empty feed rate, a servo machine saves over 1,051,200 empty bags per year. That is direct profit added to the bottom line.

2. Anti-Cutting Function

If a product is misplaced (e.g., a frozen dumpling sits on the cutting jaw), a servo motor detects the abnormal torque resistance instantly.

- The Reaction: The cutter immediately reverses or stops before cutting through the product.

- The Benefit: This prevents contamination of the knife (which requires downtime to clean) and protects the expensive cutting assembly from damage.

3. One-Touch Product Changeover

For co-packers or factories producing multiple SKUs (e.g., different sizes of bread or tray-packed foods), downtime is the enemy.

- Mechanical Changeover: 30–45 minutes. Requires tools, manual gear adjustments, and significant film waste for testing.

- Servo Changeover: 2–5 minutes. The operator selects a "Recipe" (e.g., "Croissant Large") from the HMI touchscreen. The servo motors automatically adjust the bag length, feeding speed, and cutting position.

Comparison of ROI between Servo and Mechanical Pillow Pack Machines

When evaluating a pillow pack machine purchase, the initial price tag is only part of the equation. We must look at the Total Cost of Ownership (TCO).

|

Feature |

Mechanical / Frequency Conversion Wrapper |

Servo-Driven Pillow Packing Machine |

|

Initial Investment |

Low |

Medium to High |

|

Film Waste |

High (Wastes film on start/stop & empty packs) |

Minimal (Smart start/stop, No Product No Bag) |

|

Changeover Time |

20-40 Minutes (Requires skilled mechanic) |

2-5 Minutes (Operator via Touchscreen) |

|

Maintenance |

High (Wear on chains, gears, variators) |

Low (Few moving mechanical parts) |

|

Precision |

Drifts over time as chains stretch |

Permanent Precision (Digital feedback loop) |

|

Productivity (OEE) |

Lower due to downtime & scrap |

Maximum due to continuous operation |

Here is a breakdown for decision-makers:

For a factory running a single product at low speeds, a mechanical machine is sufficient. However, for any operation prioritizing Automatic packaging efficiency, hygiene, and multi-product flexibility, the Servo machine typically pays for the price difference within 12 to 18 months through film savings and labor reduction alone.

Why Partner with Soontrue for Your Packaging Needs?

Choosing the right pillow packaging machine is not just about the hardware; it is about the algorithm behind it.

Customized Motion Algorithms: Our servo logic is tuned specifically for the characteristics of food products—handling soft, sticky, or fragile items with care.

User-Friendly HMI: We believe high-tech should not be hard to use. Our interface is designed for the factory floor, making complex servo adjustments as simple as using a smartphone.

Global Components: We utilize top-tier electrical components to ensure that your machine runs reliably, whether it's in a factory in Southeast Asia, Europe, or the Americas.

Conclusion

In the rapidly evolving pillow packing machine market, staying competitive means adopting automation that reduces labor costs.

Upgrading to a servo-driven pillow packing machine is not merely an operational upgrade; it is a financial strategy. It transforms your packaging line from a bottleneck into a competitive advantage, delivering higher speeds, lower waste, and unmatched Automatic packaging efficiency.

Ready to calculate your ROI? Whether you are a distributor looking for reliable equipment to represent or a factory manager aiming to optimize production, Soontrue is here to help.

Contact Soontrue today to discuss your specific product requirements and discover how our High-Speed Servo Solutions can revolutionize your packaging process.

FAQ

Q1: Is a servo-driven machine more difficult for my operators to run and maintain?

A: Quite the opposite. While the underlying technology is more advanced, the operator experience is significantly simpler. On a mechanical machine, tasks like changing the bag length require tools and physical adjustments. On a servo machine, the operator simply selects a pre-saved "Recipe" from the touchscreen HMI. This reduces the need for highly skilled mechanics for daily operation and dramatically cuts down on human error during changeovers. Maintenance is also simplified due to the elimination of chains, gears, and complex mechanical timing systems.

Q2: What parts actually wear out on a servo machine?

A: The common wear parts are the same as on any pillow packing machine: the cutting knife and anvil, the pull belts, and the Teflon tape on the sealing jaws. The key difference is the elimination of maintenance for the entire mechanical transmission system—no more chain tensioning, gear lubrication, or variator adjustments, which are major sources of downtime on older machines.

Q3: My factory produces only one product at a moderate speed. Is the extra investment in a servo machine still worth it?

A: It depends on your priorities. If your primary concern is the lowest possible initial cost, a mechanical machine might suffice. However, even for a single-product line, a servo machine offers significant long-term ROI. The "No Product, No Bag" feature alone saves substantial film costs over a year. Furthermore, the consistent seal quality from precise servo control reduces scrap and potential returns, and the reduced vibration leads to a longer machine lifespan with fewer breakdowns. It's an investment in operational stability and efficiency.

Q4: How does a servo machine specifically help with difficult-to-handle products, like sticky candy or very fragile crackers?

A: This is where the independent 3-axis control truly shines.

- For Sticky Products: The machine's "electronic cam" can be programmed to create a slight delay or specific motion profile, ensuring the product has fully cleared the sealing jaws before they close, preventing sticking and contamination.

- For Fragile Products: The servo motors provide smooth, "jolt-free" acceleration and deceleration. This gentle handling prevents fragile items like crackers or wafers from breaking as they are fed into the film and packaged, which is a common problem with the abrupt start/stop cycles of mechanical clutch systems.

Q5: The article focuses on a 3-axis system. Are there more advanced configurations, and when would they be needed?

A: The 3-axis system (Infeed, Film Drive, End Seal) is the industry gold standard and covers over 90% of pillow packing applications. However, additional servo axes can be integrated for even higher levels of automation. For example, a 4th axis could be used to control an automatic film splicer, allowing for non-stop film roll changes. A 5th or 6th axis could be used to integrate robotic feeding or other specialized handling devices directly into the machine's control system. These advanced configurations are typically for very high-speed, 24/7 operations where minimizing any form of manual intervention is critical.