What Is Form-Fill-Seal (FFS)? A Beginner-Friendly Introduction to the Core Technology Behind Modern Packaging

Packaging Knowledge Hub

If you're seeking packaging automation solutions, please contact us, and we'll be delighted to offer you the most tailored solution.

For the full in-depth encyclopedia-level guide, see: Packaging Machine Definition & History.

The term Form-Fill-Seal (FFS) refers to a powerful and widely used packaging technology that forms a bag or pouch from roll film, fills it with product, and seals it—all within a single automated system. For beginners in the packaging industry, FFS is one of the most important concepts to understand because it forms the foundation of how modern food, beverage, chemical, and daily-use consumer goods are packaged around the world.

The reason FFS is so dominant is simple: it combines speed, efficiency, hygiene, and cost savings into one integrated workflow. Whether you’re packaging snacks, powders, granules, liquids, frozen foods, or pet food, FFS machines offer extremely high flexibility and efficiency. FFS comes in two major structures: Vertical Form-Fill-Seal (VFFS) and Horizontal Form-Fill-Seal (HFFS), each suited to different product types and production environments.

Below is a clear, narrative-style breakdown of how FFS works, why factories rely on it, and how different industries use it to achieve continuous packaging production.

1. What FFS Really Means: Forming, Filling, and Sealing in One Machine

The heart of FFS technology is integration. Instead of using multiple separate machines to form a bag, fill it, and then seal it, the entire process is completed inside a single automated system.

Here is how the form-fill-seal sequence works:

1. Forming

A continuous roll of packaging film—often OPP/CPP, PET/PE, or aluminum-laminate material—is unwound and guided through the forming structures. Depending on the machine type, the film is shaped into a vertical tube (VFFS) or a horizontal envelope (HFFS). A forming tube, shoulder, and seal jaws are used to create the initial package shape.

2. Filling

Once the package is formed, product is dispensed into the open pouch. Different filling systems are used depending on the product:

- multihead weighers for granules and snacks

- auger fillers for powders

- volumetric cup fillers for small granules

- pump dosing systems for liquids and pastes

- piston fillers for viscous or sticky products

Accurate filling is critical because it determines product weight consistency and cost efficiency.

3. Sealing

After filling, the machine closes and seals the package.

FFS machines rely on precise control of temperature, pressure, and timing (dwell time) to achieve strong and leak-free seals. Modern machines use servo-driven sealing jaws for consistent packaging quality even at high speeds.

FFS = form + fill + seal, all in one synchronized motion.

This simple equation explains why the system is so efficient and widely used.

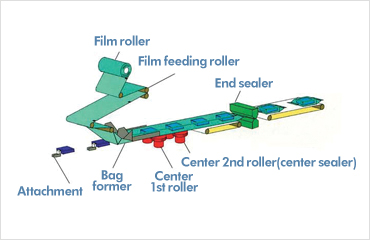

2. VFFS vs HFFS: Two Core Structures of FFS Machines

Although the term FFS sounds like a single technology, there are actually two major machine structures behind it:

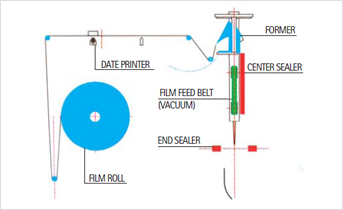

⭐ Vertical Form-Fill-Seal (VFFS)

VFFS machines pull film vertically and rely on gravity-assisted filling, making them ideal for:

- snacks, chips, nuts

- powders (coffee, flour, spices)

- granules (rice, sugar)

- frozen foods

- liquids (with pump fillers)

- pet food

- detergent powders

Typical bag types include pillow bags, gusset bags, four-side seal bags, and quad-seal bags.

VFFS machines are valued for:

- high speed

- ability to handle diverse products

- low packaging material cost

- compact footprint

- easy integration with multihead weighers and auger fillers

They are the most commonly used FFS machines in the food industry.

⭐ Horizontal Form-Fill-Seal (HFFS)

HFFS machines operate horizontally and are ideal for solid, flat, or premium packages such as:

- biscuits

- flat pouches

- stand-up pouches

- zipper bags

- medical device packaging

HFFS is often preferred when:

- product orientation is important

- zipper sealing or spout sealing is required

- flat pouches or large-format bags are used

- product cannot be dropped vertically

Because HFFS supports complex bag styles such as stand-up pouches, zipper bags, and spouted pouches, it is widely used for premium snacks, coffee, pet food, and liquid products.

3. Why Industries Choose FFS: Speed, Hygiene, Cost Reduction, and Flexibility

FFS machines have become central to modern packaging lines because they solve key production challenges:

1. High-speed production

FFS can produce from 60 to 200+ bags per minute depending on product type and machine model. High-speed sensors and servo systems keep motion synchronized and minimize downtime.

2. Hygienic and safe packaging

Because the entire process occurs inside an enclosed system, FFS reduces contamination risk, making it ideal for food, pharma, and dairy products.

3. Material efficiency

FFS uses film roll directly instead of pre-made bags, significantly lowering packaging cost and enabling more customization.

4. Multi-industry flexibility

FFS works with powders, granules, liquids, snacks, chemicals, and more. Few packaging technologies are as broadly compatible.

5. Easy integration

Factories often combine FFS machines with:

- automatic feeding systems

- multihead weighers

- inspection equipment

- case packing and palletizing equipment

This makes FFS the foundation of many large-scale packaging lines.

Conclusion

FFS machines revolutionized packaging by merging forming, filling, and sealing into one compact, efficient system. Whether vertical or horizontal, form-fill-seal technology allows factories to produce safe, consistent, and visually appealing packages at high speed, making it one of the most essential technologies in today’s manufacturing industry. Understanding VFFS, HFFS, and the core FFS workflow gives beginners a clear foundation for exploring more advanced packaging automation.

FAQ

Q1: What products can be packed using FFS technology?

FFS machines handle powders, granules, liquids, snacks, frozen foods, pet food, and many consumer goods.

Q2: Are VFFS and HFFS machines the same?

No. VFFS fills vertically using gravity, while HFFS operates horizontally and supports more complex pouch formats like stand-up pouches.

Q3: Do FFS machines reduce packaging costs?

Yes. FFS uses film rolls instead of premade bags, reducing material and labor costs.

Q4: Can FFS systems integrate with other packaging equipment?

Absolutely. FFS machines are commonly integrated with multihead weighers, auger fillers, metal detectors, case packers, and palletizing systems.