What Is a Packaging Machine? A Simple Beginner’s Guide

Packaging Knowledge Hub

If you're seeking packaging automation solutions, please contact us, and we'll be delighted to offer you the most tailored solution.

This article is part of the Soontrue Packaging Knowledge Series. For the full in-depth encyclopedia-level guide, see: Packaging Machine Definition & History.

Packaging machines are everywhere in modern life, though most people rarely notice them. Every bag of snacks, every pack of biscuits, every pouch of coffee, and every single-serve seasoning sachet passes through a piece of packaging equipment before reaching the consumer. At its simplest, a packaging machine is a mechanical system designed to automate the process of enclosing products in protective, sealed packaging so they can be transported, stored, displayed, and consumed safely. But to understand packaging machines clearly, we must go beyond the surface definition and explore what they do, why they exist, and how they became essential to almost every product we use daily.

A packaging machine performs the tasks that human hands cannot do consistently or efficiently at scale. These tasks include forming packaging materials into bags, pouches, or containers; filling them with products; sealing them tightly; and sometimes printing, labeling, counting, or sorting. Manual packaging is slow, inconsistent, and often unhygienic. As industries grew—especially food, pharmaceuticals, and consumer goods—manufacturers needed systems that could package thousands or even millions of items per day with stable quality. This demand created a wide family of packaging machines, each designed for specific product types, materials, and industry requirements.

Core Principles: How Packaging Machines Work

To understand packaging machines in a beginner-friendly way, it helps to start with a simple breakdown of what they actually handle. The first element is the product—whether it is solid, powder, liquid, paste, or something irregular. Solids like biscuits or soap bars require machines that align and wrap them consistently; powders like coffee need accurate filling and dust control; liquids require pump systems and leak-proof sealing. Every product has its own behavior, so packaging machines are engineered to work with that physical behavior rather than against it. This is why no "universal packaging machine" exists—each structure is optimized for the realities of its product category.

The second element is the packaging material. Most industrial packaging today uses roll film (a continuous sheet of laminated plastic), which can be formed into pillow bags, gusseted bags, or flat pouches through heat-sealing units. Other formats, like stand-up pouches, zipper bags, or spouted bags, are pre-made in advance and then filled by specialized equipment. Because materials vary in thickness, sealing temperature, transparency, print quality, and barrier properties, packaging machines must precisely control heat, pressure, timing, and motion to create a perfect seal. Even a slight deviation in temperature or jaw pressure can lead to weak seals, leaks, or damaged packaging. This is why modern packaging machines rely heavily on servo motors, sensors, and PLC systems to maintain precision and repeatability.

The third element is mechanical workflow, which can be understood through three words: form, fill, seal. Most packaging machines follow this sequence regardless of structure. Horizontal machines wrap products in film and seal the ends; vertical machines form a tube, drop product from above, and seal the bag; premade pouch machines use robotic arms or rotary systems to open, fill, and close pre-formed pouches. Although the motions differ, the core idea remains the same: material becomes a container, the container receives a product, and the container is sealed into a ready-to-ship format.

Beginners often assume that the differences between machines are minor—just "different shapes" of packaging. In reality, the choice of packaging machine greatly affects product quality, shelf life, efficiency, and even brand presentation. For example, a pillow bag is affordable and fast to produce, but a stand-up pouch offers far better shelf appearance and sells at a higher retail value. A food factory producing 100 packs per minute does not need the same machine as one producing 500 packs per minute. A frozen dumpling manufacturer requires machines that can handle moisture and cold environments, while a coffee producer needs high-barrier materials and strong sealing to preserve aroma. Packaging machines must adapt to all these scenarios.

Major Types of Packaging Machinery

Understanding packaging machinery becomes even clearer when we divide machines into a few fundamental structures. Flow wrapping machines, also known as pillow packing machines, handle items horizontally and produce the classic pillow-type bag. They are widely used for biscuits, breads, snacks, soap bars, and various consumer goods. The horizontal motion naturally suits products that are already shaped, placed on conveyors, and require high speed. In contrast, VFFS (Vertical Form-Fill-Seal) machines rely on gravity and are ideal for powders, granules, snacks, frozen food, liquid pouches, and more. These machines convert roll film into vertical bags while dosing systems—such as multi-head weighers, augers, or pumps—feed the product precisely into the open pouch. Premade pouch machines serve a different purpose. Instead of forming bags from film, these machines open, fill, and seal pre-made pouches such as stand-up pouches, zipper bags, and flat-bottom pouches. Because premade pouches have a premium appearance, these machines are popular for coffee beans, nuts, pet food, and high-value consumer products.

Although these structural categories may seem technical, beginners can think of them simply as different ways of organizing product flow. Horizontal machines process products like items on a moving sidewalk; vertical machines let products fall into place like raindrops; premade pouch machines "pick up and fill" bags like mechanical hands. The rest is engineering refinement—temperature control, sealing quality, motion synchronization, and automation coordination.

| Machine Type | Best For (Products) | Key Feature |

| Flow Wrapper (HFFS) | Solid items (Biscuits, Bread, Soap) | High-speed horizontal wrapping |

| VFFS Machine | Loose/Granular (Chips, Coffee, Powder) | Vertical gravity-fed bagging |

| Premade Pouch Machine | Premium Goods (Nuts, Pet Food) | Uses high-quality, pre-formed bags |

Why Automation is Essential for Industry

It is also important to understand why packaging machines are essential to industries beyond convenience. Food safety and hygiene regulations today are far stricter than they were decades ago. Many countries require airtight packaging, tamper-evident seals, batch coding, and contamination control. Packaging machines ensure that each package is sealed properly, free from human contact, and consistent across thousands of units. In pharmaceuticals, precise dosing and sterility are non-negotiable. In logistics, packaging must protect goods during long-distance shipping. In retail, attractive packaging influences consumer purchasing decisions. Packaging machines therefore do much more than "put products in bags"—they ensure compliance, efficiency, safety, and profitability.

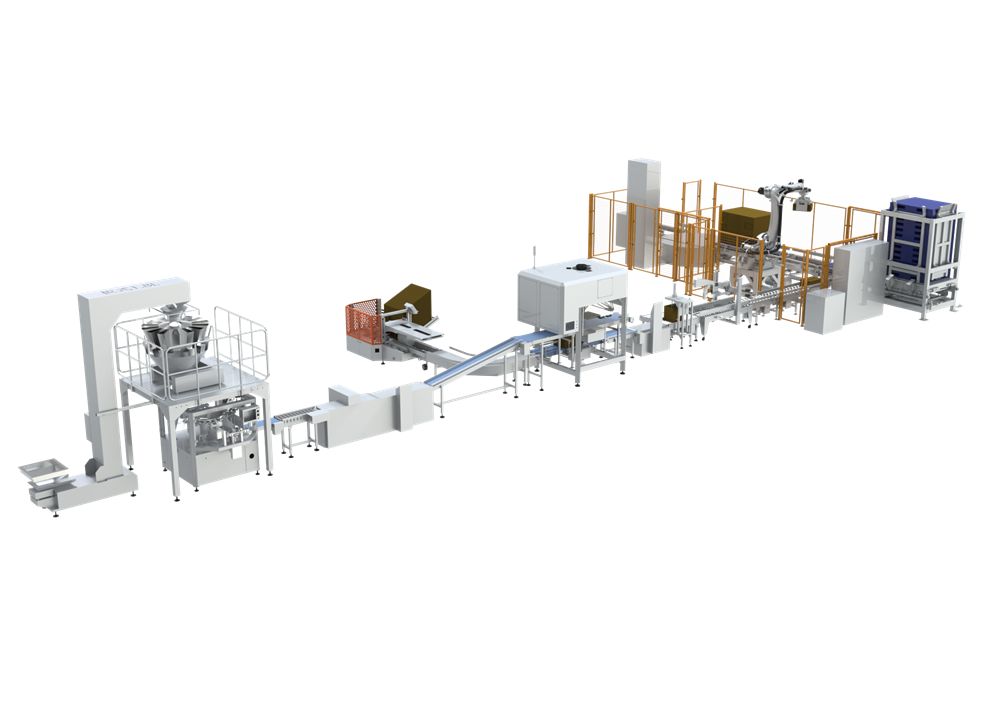

For manufacturers that are new to automation, the most reassuring aspect is that packaging machines are not isolated pieces of equipment. They integrate into complete packaging lines that may include sorting systems, dosing systems, checkweighers, metal detectors, cartoners, case packers, and palletizers. What begins as a simple packaging machine can eventually become part of a fully automated workflow that transforms production speed, reduces labor dependency, and stabilizes quality.

For a beginner, the simplest way to understand packaging machines is to see them as tools that turn loose products into sealed, standardized, and transport-ready units. Whether the product is coffee, noodles, biscuits, frozen foods, hardware parts, detergent, or medical supplies, packaging machines follow the same fundamental purpose: protect, preserve, and present. The technologies powering these machines will continue to advance—more servo drives, more sensors, smarter software—but the concept remains the same. Packaging machines exist because products need protection, industries need efficiency, and consumers need safety.

FAQ

1: What is the basic function of a packaging machine?

A packaging machine automates the process of forming, filling, and sealing packaging materials so products can be protected, transported, and stored safely. Its core purpose is to improve efficiency, ensure hygiene, and deliver consistent packaging quality.

2: What types of products can packaging machines handle?

Packaging machines can handle solids, powders, granules, liquids, pastes, and irregular-shaped products. Each product type requires a different machine structure, such as a flow wrapper for solid items or a VFFS machine for powders and snacks.

3: What is the difference between a flow wrapper (see Soontrue's Flow wrapping machines), and a VFFS machine?

A flow wrapper feeds products horizontally and creates pillow-type bags, making it ideal for biscuits, bakery items, and consumer goods. A VFFS machine forms bags vertically and relies on gravity, making it suitable for powders, granules, snacks, and liquids.

4: Why are packaging machines important for food and consumer product companies?

They ensure hygiene, reduce manual labor, increase production speed, and improve package uniformity. Packaging machines also help manufacturers meet safety regulations and extend shelf life through accurate sealing and material handling.

5: Can one packaging machine pack different products?

Some machines, such as VFFS systems and premade pouch machines, can handle multiple product types with simple changeovers. However, the best performance always comes from matching the machine structure to the product's physical properties.