Evolution Timeline of Packaging Machinery: From Manual Wrapping to Smart Automation

Packaging Knowledge Hub

If you're seeking packaging automation solutions, please contact us, and we'll be delighted to offer you the most tailored solution.

Packaging machinery has undergone more than a century of transformation, evolving from simple hand-operated devices into the highly automated, servo-driven, and intelligent systems seen in modern factories. Understanding this evolution is essential because it reveals how the needs of society, industry, technology, and global supply chains shaped today's packaging landscape. For beginners, the development timeline helps explain why so many different types of packaging machines exist today—flow wrappers, VFFS systems, carton packers, premade pouch machines, and full packaging lines—and why each generation introduced new functionality, new levels of speed, and new expectations for hygiene, reliability, and material compatibility.

Below is a structured but highly readable timeline of key stages in the evolution of packaging machinery, written in a narrative way so even non-engineers can grasp how the industry transformed over time.

1. Early Era: Manual and Mechanical Packaging (1800s–1950s)

Packaging at the start of the 19th century was almost entirely manual. Products were wrapped in paper by hand, sealed with glue, twine, or metal clasps, and prepared for small-scale distribution. This worked when production volumes were low, but as industrialization expanded and consumer goods moved beyond local markets, a more consistent and efficient approach was required.

The earliest mechanical packaging devices appeared in the late 1800s and early 1900s, accompanying the rise of mass production in food and household goods. Machines were manually loaded and mechanically driven by gears, belts, and cranks. They improved speed and consistency but lacked automation or flexibility. In this era, most packaging materials were simple: paper, wax-coated paper, tin containers, or early forms of cellophane.

By the 1930s and 1940s, bakeries, confectionery plants, and soap manufacturers began using the first generations of powered wrapping machines. These early systems introduced the idea of continuous product flow and synchronized sealing mechanisms—concepts that form the foundation of today's flow wrappers. However, adjustments were largely mechanical, changeovers were slow, and sealing control was limited, especially for food items requiring airtight packaging.

2. Expansion Era: Automated Packaging and Film Technology (1960s–1990s)

The post-war manufacturing boom created new consumer markets and accelerated the need for automation. This period saw the widespread adoption of plastic films, transforming packaging from paper-dominated to film-based systems. OPP, CPP, and polyethylene materials enabled airtight sealing, improved freshness, and increased production speeds.

This era introduced two fundamental machine structures that remain industry standards today:

horizontal flow wrappers for solid products and

vertical form-fill-seal (VFFS) machines for powders, granules, snacks, and liquids.

Flow wrapping machines evolved from mechanical to semi-automated systems capable of synchronizing conveyor speed with film pulling. VFFS machines combined forming, filling, and sealing into a vertical workflow that suited a wider range of product types and packaging formats. These innovations were crucial for industries like instant noodles, biscuits, chips, and powdered foods, enabling mass production at speeds never seen before.

Automation also expanded into secondary packaging—case erecting, case packing, bundling, and shrink wrapping. As supermarkets gained dominance, packaging became a critical tool not just for protection but for branding and display alignment. Multinational brands accelerated the demand for machines that delivered consistent quality and high output across global markets.

3. Modern Era: Servo Control, Precision, and Full-Line Automation (2000s–2015)

By the early 2000s, packaging machines had transitioned from mechanically driven systems to electronically controlled servo machines. Servo motors offered unprecedented precision, such as exact motion synchronization and dynamic speed adjustment, significantly improving sealing consistency, reducing film waste, and enabling higher speeds.

Servo-driven end sealing became a hallmark of modern flow wrappers, while VFFS machines benefited from faster jaw movements, smoother film feeding, and improved compatibility with multi-head weighers. Premade pouch machines also advanced rapidly with rotary stations, suction arm controls, and precise filling technologies capable of handling powders, granules, liquids, and viscous materials.

Full-line automation became achievable: feeding systems, packaging machines, cartoners, case packers, and palletizers were now integrated through PLC and HMI interfaces. Food factories no longer saw packaging as a standalone operation—it became part of a synchronized production ecosystem. This era also saw the rise of hygienic design, stainless-steel frames, washdown capability, and CE/GMP/HACCP compliance.

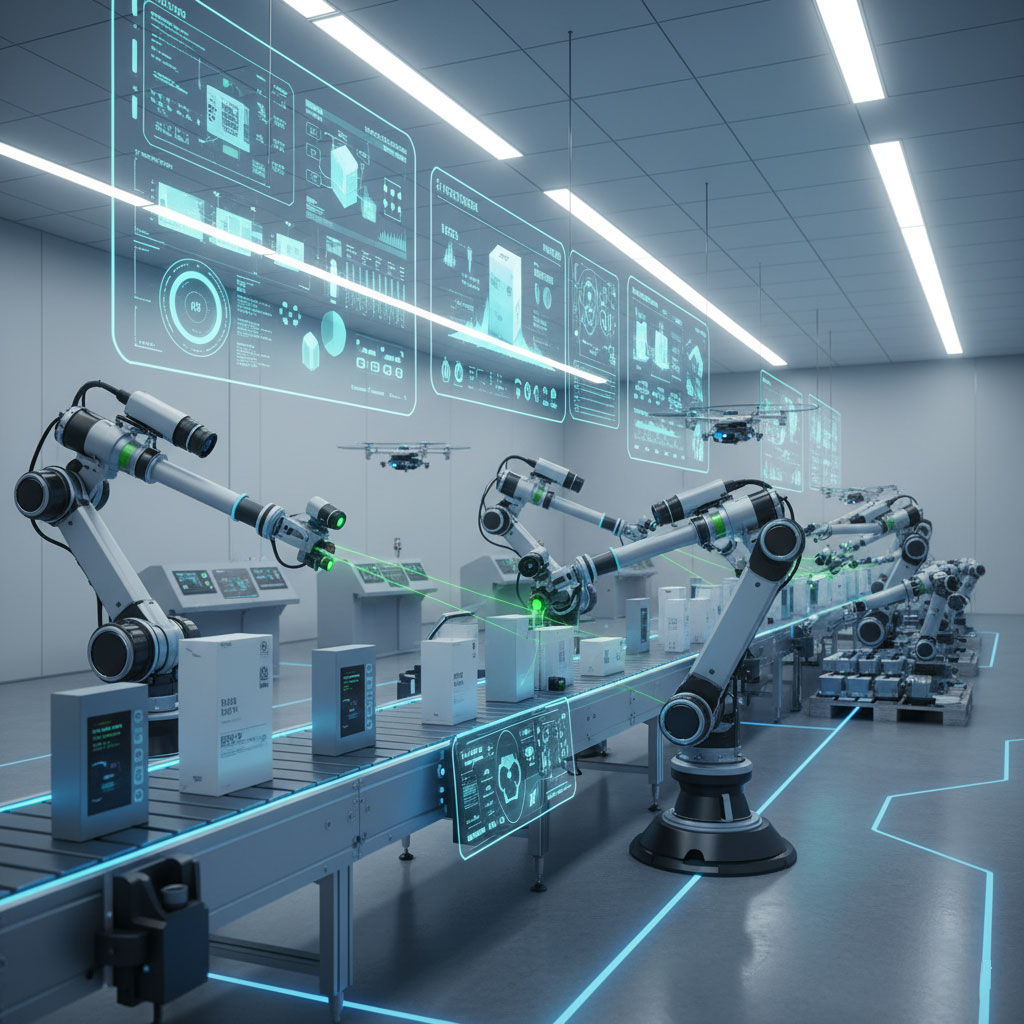

4. Smart Packaging Era: IoT, Vision Systems, and Intelligent Automation (2015–Present)

In the last decade, packaging machines have moved into the era of smart manufacturing. With sensors, IoT connectivity, motion algorithms, and vision inspection systems, packaging lines can now self-adjust, detect errors, and optimize performance automatically.

Modern innovations include:

- auto-film tracking and correction

- digital sealing temperature control

- AI-assisted feeding and sorting

- robotic pick-and-place systems

- predictive maintenance

- data logging for traceability

Premade pouch packaging has become more premium, with high-speed rotary systems and multi-station controls. Flow wrappers and VFFS machines incorporate servo motion profiles that reduce downtime and improve overall equipment effectiveness (OEE).

Today’s packaging lines are transitioning from "automated" to "intelligent"—capable of learning patterns, adapting to product irregularities, and integrating directly with MES/ERP systems. Consumer trends like sustainability, recyclable films, and lightweight packaging are influencing machine design, while global factories increasingly demand flexible, high-speed, low-waste solutions.

Conclusion

The evolution of packaging machinery reflects the evolution of modern manufacturing itself. From manual wrapping to servo-controlled automation and now intelligent, data-driven packaging ecosystems, the industry has repeatedly transformed in response to market demands, food safety standards, supply chain complexity, and technological innovation. Understanding this timeline gives manufacturers and engineers a deeper appreciation for why different machines exist today and how each generation of innovation reshaped global production standards.

Related Knowledge Articles

- What Is a Packaging Machine? A Beginner's Guide

- Primary, Secondary & Tertiary Packaging Explained

- What Is Form-Fill-Seal (FFS)?

- Hygiene Standards in Food & Pharma Packaging

- Why Packaging Is Essential in Modern Manufacturing

- (Coming Soon) Key Innovations in Modern Packaging Machinery

FAQ

Q1: When did automated packaging machines first appear?

Automated packaging machines began gaining widespread adoption in the 1960s and 1970s as film-based packaging materials became common and manufacturing volumes increased.

Q2: What technological breakthrough had the biggest impact on packaging machinery?

Servo motor technology had the biggest impact, enabling precise motion control, faster speeds, and better sealing consistency across all machine types.

Q3: How did packaging films change machine evolution?

Plastic films allowed airtight sealing, faster wrapping, better shelf life, and mass production—leading to the rise of flow wrappers and VFFS systems.

Q4: Why are modern packaging machines considered intelligent?

They incorporate sensors, vision systems, IoT connectivity, and predictive maintenance, enabling automatic adjustment and data-driven optimization.