How to Choose a VFFS Machine: Complete Selection Process for Food Industry Professionals

VFFS Machine Blog

If you're seeking packaging automation solutions, please contact us, and we'll be delighted to offer you the most tailored solution.

In modern food production, the Vertical Form Fill Seal (VFFS) machine is an absolute cornerstone. Yet, the single biggest mistake companies make when purchasing one is focusing solely on the sticker price. This oversight often leads to unforeseen, long-term operational costs that ultimately erode profitability.

This ultimate guide is designed to fundamentally shift your purchasing perspective. We won't just teach you how to "buy" a machine; we will guide you on how to strategically invest in a production engine that delivers continuous returns. We will break down every detail of Total Cost of Ownership (TCO), critical technical specifications, performance efficiency, and long-term maintenance.

After reading this, you will be able to confidently answer the most important question: "Which VFFS machine will deliver the highest Return on Investment (ROI) for my business?"

Understanding VFFS Machine Product Compatibility Requirements

Food Product Classification and Machine Matching

1.Dry Food Products and VFFS Configuration

Granular products like snacks, cereals, and nuts require specific machine configurations for optimal performance. Uniform particle sizes (3-15mm) work best with multihead weighers, achieving ±0.5g accuracy at speeds up to 120 bags/minute. Mixed particle products need combination weighers with larger hoppers to prevent segregation.

Powder products including spices, flour, and protein supplements demand auger filling systems designed for bulk density variations. Free-flowing powders (bulk density >0.6 g/cm³) enable high-speed operations at 20-60 bags/minute, while challenging powders require specialized anti-bridging mechanisms.

2.Liquid and Semi-Liquid Food Applications

Liquid and Paste Products (Sauces, Condiments, Dairy): Packaging speeds for these products generally range from 20-100 bags/minute. The specific speed and configuration depend on the product's viscosity (measured in centipoise, cP), which directly dictates the required pump system:

Piston Pumps: Ideal for low-viscosity liquids (<500 cP).

Gear Pumps: Used for medium-viscosity products (500-5000 cP).

Progressive Cavity Pumps: Necessary for high-viscosity pastes (>5000 cP).

Food Safety and Material Compatibility Standards

Temperature-sensitive products like chocolate require sealing temperatures below 140°C with rapid cooling cycles. Frozen food packaging demands cold-sealing capabilities or modified atmosphere packaging integration.

Chemical compatibility assessment includes pH levels, oil content, and corrosive properties. Acidic products (pH <4.5) necessitate stainless steel 316L construction, while high-fat products require specialized non-stick surface treatments and enhanced cleaning systems.

VFFS Packaging Film Material Selection Guide

Monolayer Film Applications for Food Packaging

Polypropylene (PP) Films: Excellent moisture resistance and rigidity, ideal for dry snack products

Cast Polypropylene (CPP): Superior heat-sealing performance with high transparency, commonly used as inner sealing layers

Polyethylene (PE): Cost-effective solution for basic food packaging applications

Ethylene-Vinyl Acetate (EVA): Outstanding flexibility and low-temperature sealing, perfect for frozen food products

Laminated Composite Films for Enhanced Protection

OPP/CPP Structures: Industry-standard combination providing glossy exterior with reliable heat-sealing capability, widely used for snacks, biscuits, and nuts

PET/PE Laminates: Premium option offering exceptional stiffness, puncture resistance, and transparency with reliable sealing properties

High-Barrier Films: PVDC-coated structures provide superior oxygen and moisture protection, extending shelf life for meat products and prepared foods

The Core Metrics: Deconstructing VFFS Machine TCO & ROI

Smart investors look at the complete financial picture. The Total Cost of Ownership (TCO), not the initial price, is what truly determines the success or failure of your VFFS machine investment.

A. Initial Investment (CapEx - Capital Expenditure)

This is the most visible part, but it requires a detailed breakdown:

- Base Machine Price: The cost of the main machine body.

- Optional Components: Costs for multihead weighers, auger fillers, date coders, hole-punch devices, nitrogen flushing systems, etc.

- Shipping & Installation: International freight, customs duties, and on-site installation and commissioning fees.

B. The Hidden Factory: Operational Costs (OpEx - Operating Expenditure)

This is where profits are made or lost:

- Energy Consumption: While a servo-driven machine has a higher initial cost, its energy consumption is far lower than a traditional pneumatic machine, leading to significant long-term savings on electricity bills.

- Compressed Air Usage: Pneumatic components are major consumers of compressed air, a massive and often overlooked hidden cost in many factories.

- Maintenance & Spare Parts: The replacement frequency and cost of wear-and-tear parts (e.g., heating elements, thermocouples, belts, cutting blades) directly impact TCO.

- Film & Product Giveaway: A high-precision dosing system (like a multihead weigher) minimizes product giveaway, potentially saving you thousands or even tens of thousands of dollars in raw material costs annually.

- Labor & Training: The complexity of operation, ease of film and bag former changes, and time required for cleaning all translate directly into labor costs.

C. Calculating Your Return on Investment (ROI)

A simplified formula is: ROI = (Gain from Investment - Cost of Investment) / Cost of Investment

Here, "Gain from Investment" can be quantified as:

- Labor costs saved through automation.

- Increased daily output due to higher speed.

- Reduced raw material waste from improved accuracy.

- Improved Overall Equipment Effectiveness (OEE) from reduced downtime.

Technical Deep Dive: Matching the Best Specs to Your Product

Choosing the right specifications is the first step toward optimizing your TCO.

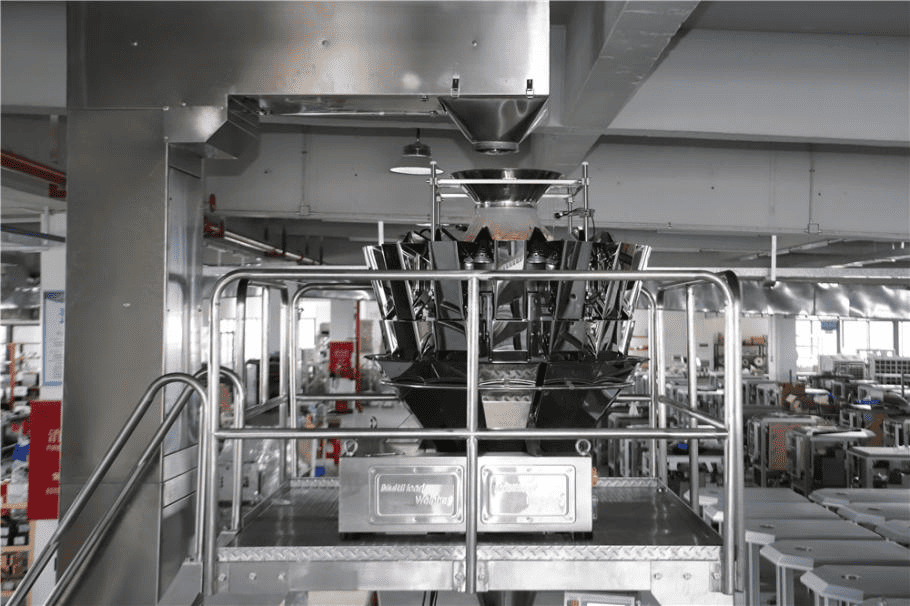

A. Dosing System Showdown: Multihead Weigher vs. Auger Filler vs. Volumetric Cup

| System Type | Best For | Accuracy | Speed | Relative Cost |

| Multihead Weigher | Granules, mixes, irregular shapes (chips, nuts) | Excellent (±0.1-1g) | High | High |

| Auger Filler | Powders (coffee, milk powder, spices) | Good | Medium | Medium |

| Volumetric Cup | Uniform, small granules (sugar, salt, rice) | Fair (±1-2%) | Very High | Low |

Investment Insight: For high-value products, the superior accuracy of a multihead weigher provides a rapid ROI by minimizing giveaway. For powders, choosing an auger filler with a servo drive ensures better stability and precision.

B. The Drive System Debate: Servo vs. Pneumatic

- Pneumatic System: Lower initial investment. However, it has higher long-term operational costs (electricity, air compressor maintenance) and its speed and precision can be affected by air pressure fluctuations.

- Servo System: Higher initial investment. But it offers extremely low energy consumption, smooth and precise operation, faster speeds, and more consistent bag length control, resulting in a superior long-term TCO.

C. Sealing Technology Choices

- Heat Sealing: The most common and cost-effective technology, suitable for most laminated films.

- Ultrasonic Sealing: Ideal for heat-sensitive products (like chocolate) or for sealing areas contaminated with dust. It provides a more aesthetic seal but comes at a higher cost.

Performance Maximization: A Guide to Speed, Efficiency & Changeover

A machine's throughput capacity directly dictates your profitability.

A. Understanding VFFS Machine Speed: Rated vs. Actual Output

Never judge a machine by its "maximum speed" on a brochure. The actual output is typically only 70-85% of the rated speed and is influenced by:

- Product Flowability: Sticky or poor-flowing products require longer settling times.

- Bag Length: Longer bags require more film travel and filling time, reducing speed.

- Film Material: Certain films need longer heating and cooling times to ensure a quality seal.

- Dosing System: The speed of the dosing system is often the bottleneck for the entire machine.

B. Changeover Time: The Hidden Cost Center

If your factory requires frequent changes between products or package sizes, changeover time is the key to efficiency. Choosing a machine that supports "tool-less" rapid changeovers can reduce downtime from over an hour to just 15 minutes, dramatically increasing effective production time and boosting your ROI.

Long-Term Value: Maintenance, Cleaning & Troubleshooting

A great machine doesn't just run fast—it must also be easy to maintain.

A. Preventive Maintenance Checklist

- Daily: Clean photo-eye sensors, wipe down machine surfaces, check air pressure.

- Weekly: Inspect and clean cutting blades, check heating elements.

- Monthly: Check the tension of film-pulling belts, lubricate designated components.

A solid maintenance plan can reduce the risk of unexpected downtime by up to 80% and extend the machine's lifespan.

B. Troubleshooting Common VFFS Problems

- Problem: Seals are weak or burned through?

Solution: Check if the temperature setting is correct. Adjust the sealing pressure. Clean any residue from the surface of the sealing jaws.

- Problem: Film is tracking improperly (drifting)?

Solution: Check if the film roll is centered. Adjust the position of the photo-eye sensor. Check if the tension of the film-pulling belts is even.

- Problem: Bag length is inconsistent?

Solution: Clean and calibrate the registration mark sensor (photo-eye). Check that the parameters for the servo film-pulling system are correct.

The 5-Step Selection Process: A Systematic Workflow from Need to Contract

Phase 1: Requirements Assessment (Week 1-2)

Document comprehensive product specifications, including physical properties, chemical characteristics, and regulatory requirements. Establish production targets, quality standards, and budget parameters with clear mandatory versus preferred features.

Phase 2: Vendor Evaluation and Market Research (Week 3-4)

Research manufacturers with proven food industry track records. Evaluate technical support capabilities, spare parts availability, and local service presence. Request detailed proposals from 3-5 qualified suppliers focusing on food safety compliance and regulatory certifications.

Phase 3: Testing and Performance Validation (Week 5-8)

Conduct comprehensive machine demonstrations using actual food products. Evaluate cleaning procedures, changeover efficiency, and maintenance requirements. Request performance data, including speed, accuracy, reliability metrics, and food safety compliance documentation.

Phase 4: Commercial Analysis and Contract Negotiation (Week 9-10)

Compare the total cost of ownership across vendors, including energy consumption, maintenance costs, and operator training requirements. Negotiate warranty terms, service agreements, and performance guarantees specific to food industry applications.

Phase 5: Implementation and Commissioning (Week 11-16)

Develop installation schedules coordinating facility modifications, utility connections, and comprehensive staff training programs. Establish commissioning protocols including food safety validation, performance verification, and regulatory compliance documentation.

FAQ

Q: How do I determine the right VFFS machine speed for my food production requirements?

A: Calculate hourly output needs based on daily targets divided by operating hours, then add a 15-20% buffer for maintenance. Size machines at 110-125% of calculated requirements.

Q: What's the difference between multihead weighers and volumetric filling for food products?

A: Multihead weighers provide ±0.1-0.5g accuracy, ideal for variable-density foods like snacks. Volumetric systems offer cost-effective ±1-2% accuracy for consistent products like grains.

Q: Which technical specifications matter most when comparing food packaging machines?

A: Prioritize filling accuracy, sealing capabilities, food-grade construction materials, cleaning accessibility, and integration with existing food safety systems.

Q: How do I ensure packaging film compatibility with my food products?

A: Test sealing performance with actual films at various settings. Consider barrier properties, material thickness (25-80 microns), and food safety certifications.

Q: What are the key factors for successful VFFS implementation in food facilities?

A: Focus on comprehensive training, detailed cleaning protocols, preventive maintenance schedules, quality control procedures, and regulatory compliance documentation.

Q: What is the general price range for a VFFS machine?

A: The price of a VFFS machine can range widely, from $15,000 for a basic model to over $150,000 for a fully-featured, high-speed system. The final price depends on the dosing system, speed, level of automation, and brand. The key is to evaluate its TCO, not its initial price.

Q: How can I reduce the operational cost of my VFFS machine?

A: Prioritize servo-driven models to save energy. Invest in high-accuracy dosing systems to reduce waste. Implement a strict preventive maintenance schedule to avoid costly repairs. Optimize your packaging film material and thickness.

Q: From a cost perspective, should I choose a servo or pneumatic VFFS machine?

A: If you have a tight budget and lower production demands, a pneumatic system is a low-cost entry point. If you are focused on long-term efficiency, high speed, and precision, a servo system typically pays back its extra investment within 2-3 years through energy savings and reduced waste, offering a higher ROI.

Conclusion: The Shift from Buyer to Strategic Investor

Choosing a VFFS machine is a far-reaching business decision. By shifting your focus from "price" to "Total Cost of Ownership (TCO)" and "Return on Investment (ROI)," you transform from a simple equipment buyer into a strategic investor who is shaping the future profitability of your company.

You now have the knowledge required to make an informed decision. It's time to put this theory into practice.

If you're ready to receive a detailed equipment configuration and ROI analysis based on your specific products and capacity targets, contact our expert team today. We are ready to help you build the packaging line that creates maximum value for your business.