How to Maintain and Care for VFFS Machines

VFFS Machine Blog

If you're seeking packaging automation solutions, please contact us, and we'll be delighted to offer you the most tailored solution.

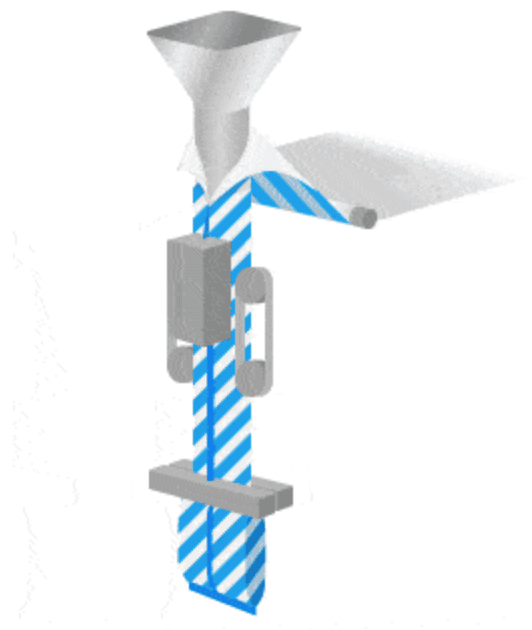

Vertical Form Fill Seal (VFFS) machines are the backbone of modern food packaging operations, delivering consistent, efficient, and hygienic packaging solutions across diverse product lines. From granular to liquid product, these sophisticated systems ensure product integrity while maximizing operational efficiency. However, like any precision equipment, VFFS machines require systematic maintenance and care to maintain peak performance, minimize downtime, and extend operational lifespan.

By implementing proper maintenance protocols, businesses can significantly reduce operational costs, improve product quality, and maintain compliance with stringent food safety regulations. Whether you're managing a single VFFS unit or overseeing multiple production lines, understanding these maintenance principles is essential for sustainable business operations and competitive advantage in today's demanding marketplace.

The Importance of Routine Maintenance of VFFS Machines

Daily maintenance forms the foundation of successful VFFS machine operation, directly impacting production efficiency, product quality, and equipment longevity. Food packaging facilities that implement rigorous daily maintenance protocols experience up to 40% fewer unexpected breakdowns and achieve significantly higher Overall Equipment Effectiveness (OEE) rates.

Key Daily Maintenance Activities:

Visual Inspections: Begin each shift with comprehensive visual assessments of sealing jaws, film transport systems, and product delivery mechanisms. Look for signs of wear, contamination, or misalignment that could compromise packaging integrity or food safety standards.

Cleaning Protocols: Food-grade environments demand meticulous cleaning procedures. Daily sanitization of contact surfaces, removal of product residues, and inspection of hygiene-critical components prevent cross-contamination and maintain compliance with HACCP requirements.

Lubrication Management: Proper lubrication of moving parts reduces friction, prevents premature wear, and ensures smooth operation. Daily checks of lubrication points, particularly on film transport rollers and sealing mechanisms, prevent costly component failures.

Performance Monitoring: Track key performance indicators including seal quality, film usage efficiency, and production speeds. Daily documentation helps identify performance trends and enables proactive maintenance interventions before problems escalate into costly repairs or production interruptions.

Troubleshooting and Solutions for Common VFFS Machine Faults

Understanding common VFFS machine issues and their solutions enables rapid problem resolution, minimizing production disruptions and maintaining consistent output quality.

Sealing Problems:

1)Poor Seal Quality: Often caused by incorrect temperature settings, contaminated sealing bars, or improper pressure adjustment.

Solution: Calibrate sealing temperature according to film specifications, clean sealing surfaces regularly, and adjust pressure settings systematically.

2)Incomplete Seals: Usually results from misaligned sealing jaws or insufficient dwell time.

Solution: Realign sealing components using precision measurement tools and adjust timing parameters to allow adequate heat transfer.

Film Transport Issues:

1)Film Tracking Problems: Commonly caused by uneven tension, worn guide rollers, or incorrect threading.

Solution: Inspect and replace worn components, adjust tension settings, and ensure proper film path alignment.

2)Film Breaks: Often result from excessive tension, sharp edges on equipment, or material defects.

Solution: Reduce film tension gradually, inspect and smooth sharp edges, and verify film quality specifications.

Product Delivery Challenges:

1)Overfilling/Underfilling: Typically caused by inconsistent product flow or incorrect volumetric settings.

Solution: Calibrate dosing systems regularly, inspect product delivery mechanisms, and adjust parameters based on product characteristics.

2)Product Contamination: Results from inadequate cleaning or worn contact surfaces. Solution: Implement enhanced cleaning protocols and replace worn components that contact food products immediately.

Maintenance Schedule and Precautions

Establishing a systematic maintenance schedule ensures optimal VFFS machine performance while preventing unexpected breakdowns that can severely impact production schedules and profitability. A well-structured maintenance program balances operational efficiency with equipment longevity.

| Frequency | Component | Action | Key Checkpoint |

| Daily | Sealing Jaws | Clean & Inspect | Remove product residue; check for Teflon tape wear. |

| Daily | Film Path | Align | Ensure film is centered on the forming collar. |

| Weekly | Cutting Knife | Check Sharpness | Replace if bags have ragged edges. |

| Monthly | Drive Belts | Tension Check | Tighten if slippage occurs (bag length errors). |

Weekly Maintenance Tasks:

- Deep cleaning of all food-contact surfaces using approved sanitizers

- Inspection and replacement of worn sealing elements

- Calibration of temperature and pressure sensors

- Verification of safety system functionality

Monthly Maintenance Requirements:

- Comprehensive lubrication of all mechanical components

- Belt tension adjustments and alignment checks

- Electrical connection inspections and tightening

- Filter replacement in pneumatic and hydraulic systems

Quarterly Intensive Maintenance:

- Complete disassembly and inspection of critical components

- Replacement of wear parts according to manufacturer specifications

- Precision calibration of all measurement and control systems

- Documentation and analysis of performance trends

Critical Safety Precautions: Always disconnect power sources before maintenance activities. Use proper lockout/tagout procedures to prevent accidental startup. Ensure maintenance personnel wear appropriate personal protective equipment and follow confined space protocols when applicable. Maintain detailed maintenance logs for regulatory compliance and warranty protection.

Environmental Considerations: Food processing environments require special attention to moisture control, temperature fluctuations, and contamination prevention during maintenance activities. Schedule intensive maintenance during production breaks to minimize exposure to environmental contaminants.

Best Practices for Preventive Maintenance

Preventive maintenance represents the most cost-effective approach to VFFS machine management, reducing emergency repairs by up to 60% while extending equipment lifespan significantly. Implementing these best practices ensures consistent performance and maximizes return on investment.

Predictive Maintenance Integration: Modern VFFS systems benefit from IoT sensors and monitoring systems that provide real-time performance data. Implement vibration analysis, thermal imaging, and oil analysis programs to predict component failures before they occur. This approach enables planned maintenance during scheduled downtime rather than emergency repairs during peak production periods.

Component Lifecycle Management: Maintain detailed records of component installation dates, operating hours, and performance characteristics. Replace wear parts based on actual usage data rather than arbitrary time intervals. This data-driven approach optimizes component replacement timing and reduces unnecessary maintenance costs.

Supplier Partnership Programs: Establish strong relationships with OEM suppliers and authorized service providers. These partnerships provide access to genuine parts, technical expertise, and training programs that enhance maintenance effectiveness. Regular supplier audits ensure continued service quality and parts availability.

Performance Benchmarking: Establish baseline performance metrics for each VFFS machine including cycle times, energy consumption, and quality parameters. Regular comparison against these benchmarks identifies performance degradation early, enabling proactive interventions before problems impact production quality or efficiency.

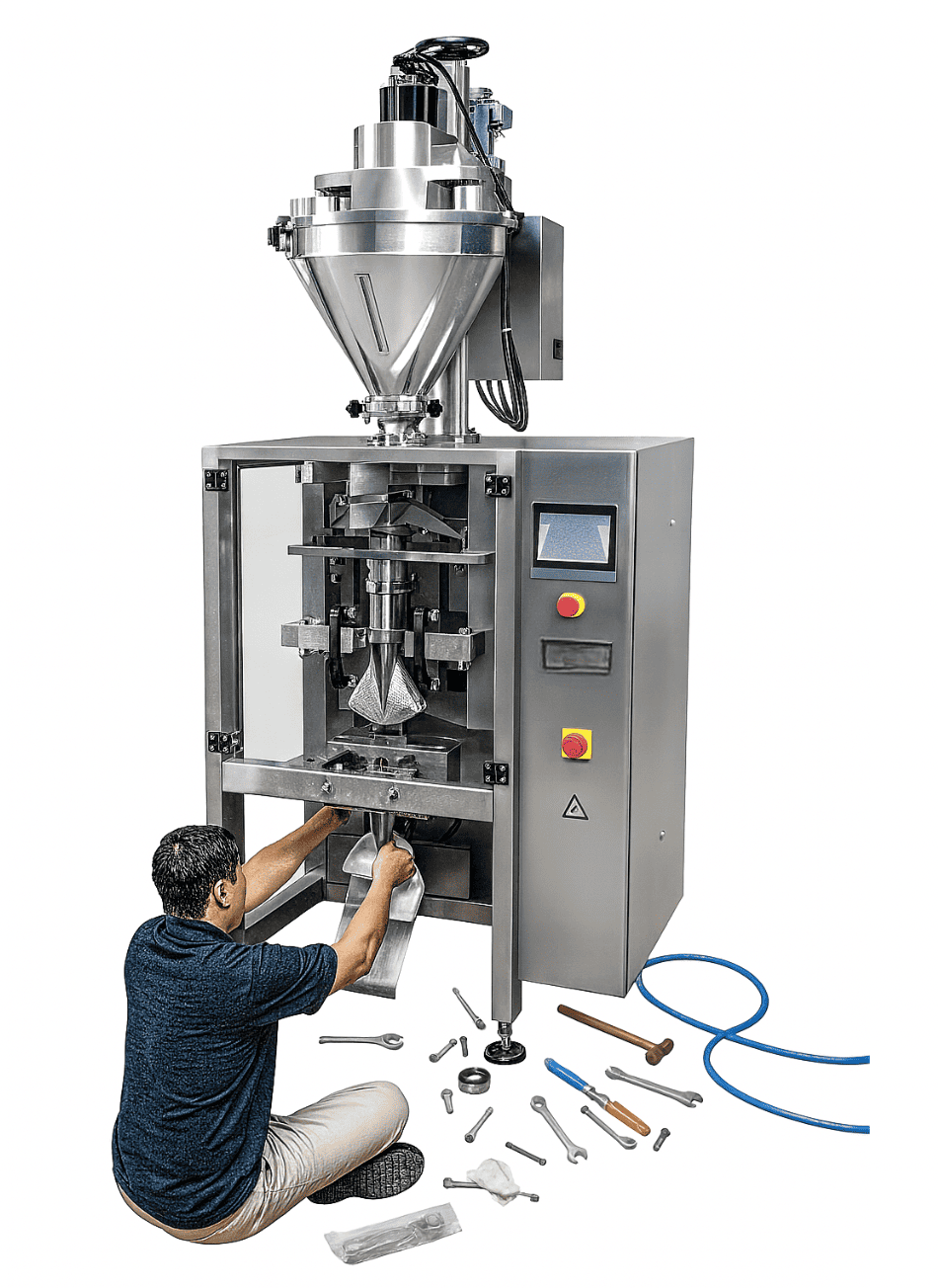

Essential Maintenance Tools and Equipment

Professional VFFS machine maintenance requires specialized tools and equipment to ensure precision, safety, and efficiency. Investment in quality maintenance tools reduces repair time, improves accuracy, and prevents damage to sensitive components.Basic Tool Requirements:

Precision torque wrenches for critical fastener specifications

Digital multimeters for electrical system diagnostics

Temperature measurement devices for sealing system calibration

Alignment tools for belt and roller positioning

Food-grade lubricants and cleaning solutions

Advanced Diagnostic Equipment:

Thermal imaging cameras for heat distribution analysis

Vibration analyzers for bearing and motor condition monitoring

Ultrasonic thickness gauges for film measurement

Digital pressure gauges for pneumatic system verification

Oscilloscopes for electrical signal analysis

Safety and Contamination Prevention: All maintenance tools must meet food-grade standards and be easily sanitized. Maintain separate tool sets for different production areas to prevent cross-contamination. Regular tool calibration ensures measurement accuracy and maintains quality standards throughout the maintenance process.

Importance of Staff Training

Effective VFFS machine maintenance depends heavily on skilled personnel who understand both the technical requirements and safety protocols essential for food packaging operations. Comprehensive training programs ensure consistent maintenance quality while protecting both equipment and personnel.

Core Training Components: Technical competency development should cover electrical systems, mechanical components, and control software operation. Personnel must understand troubleshooting procedures, safety protocols, and food safety regulations. Regular skills assessments ensure maintained competency levels across all maintenance team members.

Certification and Compliance: Food industry maintenance personnel require specialized certifications in food safety, equipment operation, and industry-specific regulations. Regular certification renewals ensure continued compliance with evolving industry standards and regulatory requirements.

Ongoing Education Programs: Technology advancement in VFFS systems requires continuous learning. Establish partnerships with equipment manufacturers for ongoing training programs, technical updates, and best practice sharing. This investment in personnel development directly correlates with improved equipment performance and reduced maintenance costs.

Knowledge Management Systems: Document all maintenance procedures, troubleshooting guides, and lessons learned in accessible knowledge management systems. This ensures consistent practices across shifts and preserves institutional knowledge when personnel changes occur.

Rebuild vs. Replace: When is it time for a new VFFS machine?

One of the toughest questions for production managers is deciding when to stop repairing an aging machine and invest in a new one. While rebuilding seems cheaper upfront, the hidden costs of downtime and obsolete technology often drain profitability over time.

According to packaging industry standards, you should consider replacing your VFFS machine if:

- The 50% Rule: The cost of a major rebuild approaches 50% of the price of a new machine.

- The Maintenance Threshold: Your annual maintenance costs exceed 15% of the asset's replacement value.

- Obsolete Parts: You are frequently waiting weeks for electronic components (PLC, servo drives) that are no longer supported by the manufacturer.

- OEE Drop: Your Overall Equipment Effectiveness (OEE) has dropped below 65% due to frequent micro-stops.

| Comparison Factor | Rebuilding Old Machine | Upgrading to New Soontrue VFFS |

|---|---|---|

| Maintenance Needs | High (Frequent lubrication & adjustments) | Low (Servo-driven, fewer wear parts) |

| Changeover Time | Slow (Manual tools required) | Fast (Tool-less, saved recipes) |

| Spare Parts Cost | Expensive (Custom/Obsolete parts) | Standardized (Off-the-shelf availability) |

💡 The Soontrue Advantage

Modern Soontrue machines feature advanced servo-driven systems that reduce maintenance needs by 30% compared to older pneumatic models. Our open-frame design allows for easier cleaning, ensuring you spend less time fixing and more time packing.

View Our Low-Maintenance VFFS Models ➜

Conclusion

By following this guide, you are well on your way to achieving peak operational efficiency. But what if, despite your best efforts, you're still struggling with frequent downtime, high spare parts costs, or film waste that hurts your margins?

Sometimes, maintenance can only do so much. Our latest generation of VFFS machines are engineered from the ground up for minimal maintenance and maximum uptime, featuring quick-changeover parts and predictive diagnostics.

Curious to see the difference a modern system can make? Download Maintenance Checklist for a side-by-side comparison of your current maintenance costs versus the operational savings of a new machine.

FAQ

Q:How often should VFFS machine sealing elements be replaced?

A:Sealing element replacement frequency depends on production volume, packaging materials, and operating conditions. Typically, high-volume operations require replacement every 3-6 months, while lower-volume facilities may extend intervals to 6-12 months. Monitor seal quality consistently to determine optimal replacement timing.

Q:What are the most critical spare parts to maintain in inventory?

A:Essential spare parts include sealing bars, drive belts, pneumatic cylinders, temperature sensors, and forming tubes. Maintain 2-3 months of inventory for high-wear components and at least one spare for critical single-point-of-failure components.

Q:How can we reduce film waste during maintenance activities?

A:Implement standardized setup procedures, train operators in proper film threading techniques, and use film edge guides to prevent tracking problems. Regular maintenance of film transport systems reduces waste by ensuring consistent operation.

Q:What safety protocols are essential during VFFS maintenance?

A:Always use lockout/tagout procedures, disconnect power sources, and wear appropriate PPE. Ensure confined space protocols when working inside machine enclosures. Maintain clear communication with production staff during maintenance activities.

Q:How do environmental factors affect VFFS machine performance?

A:Temperature fluctuations, humidity variations, and dust accumulation significantly impact performance. Maintain stable environmental conditions and implement regular cleaning schedules to minimize these effects.

Q:What training certifications should maintenance staff obtain?

A:Key certifications include food safety (HACCP), electrical safety, mechanical systems, and manufacturer-specific training programs. Regular recertification ensures maintained competency levels.

Q:How can predictive maintenance reduce operational costs?

A:Predictive maintenance using sensors and data analysis can reduce unplanned downtime by 35-45% and extend equipment life by 20-30%. Investment in monitoring systems pays for itself through reduced emergency repairs and improved efficiency.

Q:What documentation is required for regulatory compliance?

A:Maintain detailed maintenance logs, parts replacement records, calibration certificates, and training documentation. These records are essential for FDA inspections and quality audits in food packaging operations.