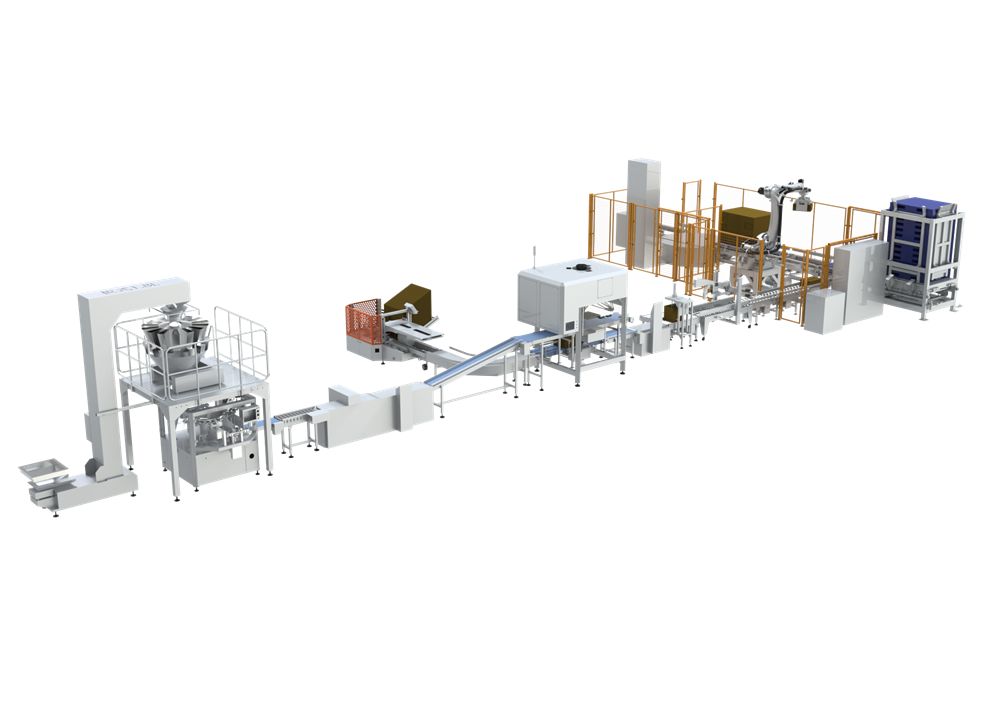

Soontrue offers complete carton and box secondary packaging solutions, including:

- Case Erecting Machines: Automatic carton forming for high-speed production lines.

- Case Packers: Flexible systems for loading pillow bags, pouches, or boxed products into cartons (side load, top load, or robotic pick-and-place).

- Case Sealers: Reliable sealing solutions to ensure product security and stability during distribution.

- Robotic Palletizers: Intelligent stacking systems to optimize warehouse and logistics operations.

- Together, these systems form an integrated carton & box secondary packaging line that delivers speed, consistency, and reliability.

Why Choose Soontrue for Carton & Box Secondary Packaging Solutions?

- Complete portfolio covering case erecting, packing, sealing, and palletizing.

- Flexible configurations adaptable to multiple carton sizes and packing patterns.

- Proven industry experience across food, household goods, and consumer electronics.

- Automation-driven efficiency that reduces labor and improves throughput.

- Global service network ensuring fast delivery and technical support.

Customer Cases

- A global food manufacturer adopted Soontrue's carton packaging line, reducing labor costs by 40% and improving carton consistency for export logistics.

- A household goods company integrated case erectors, packers, and robotic palletizers, achieving a fully automated end-of-line packaging solution.

FAQ About Carton & Box Secondary Packaging Solutions

Q1: What is the difference between carton and box secondary packaging?

A: In practice, carton and box secondary packaging refer to the same process—organizing products into cartons or boxes for logistics and retail readiness.

Q2: Can one packaging line handle multiple carton sizes?

A: Yes. Soontrue's case erectors, packers, and palletizers are designed to handle multiple sizes and formats with quick changeover features.

Q3: What industries benefit most from carton secondary packaging?

A: Food, beverage, household goods, personal care, and consumer electronics industries all use carton & box packaging solutions.

Q4: How does automation improve carton and box packaging?

A: Automation reduces manual labor, ensures consistent sealing, improves stacking accuracy, and accelerates overall end-of-line packaging.