3+1-axis Robotic Box Packing Machine

3+1-axis Robotic Box Packing Machine Typical Applications

- Food & Beverage: biscuits, bread, snacks, dairy, bottled drinks

- Pharmaceuticals & Healthcare: medicine packs, personal care products, supplements

- Household Goods: tissues, cleaning products, detergents, daily consumables

- Electronics & Industrial Products: small appliances, components, hardware items

- E-commerce & Logistics: mixed product box packing for shipping and fulfillment

The WS-1200 is an advanced robotic case packing solution equipped with a 3+1-axis robotic arm, engineered to automate product loading into cartons with speed, accuracy, and flexibility. Unlike conventional case packers that rely on fixed mechanical movements, the WS-1200 integrates servo-driven robotics, vision-guided positioning, and customizable grippers, enabling it to handle a wide range of product types, shapes, and weights.

Its flexible packing patterns allow manufacturers to configure multiple box layouts, whether single-product lines or mixed-product assortments. The system is designed to reduce manual labor by automating repetitive and labor-intensive packing tasks, ensuring consistent quality, faster cycle times, and improved safety.

As part of Soontrue’s End-of-Line Packing Series, the WS-1200 fits seamlessly into fully automated packaging lines, working alongside erectors, sealers, and palletizers to optimize overall production efficiency.

Machine Parameters

| Specifications | WS-800 | WS-1200 |

| Pick-up speed | 60-80 pcs/min | 30-50 pcs/min |

| Rated payload | ≤5 kg | ≤5 kg |

| Max. arm span | 800 mm | 1200 mm |

| Robot power | 3.0 Kw | 3.0 Kw |

| Power supply | 220V/1Ph/50Hz | 220V/1Ph/50Hz |

| Machine weight | 600 kg | 600 kg |

| Machine dimensions | 1800x1400x1985 mm | 2240x1440x2300 mm |

📌 Reference: Internal test data by Soontrue R&D Lab (2024)

Key Features

3+1-axis Robotic Arm: The WS-1200 is equipped with a 3+1-axis robotic arm, enabling precise and efficient handling of products. This advanced mechanism offers flexibility in product arrangement, ensuring optimal packing accuracy.

Servo-Controlled System: The machine utilizes a high-precision servo-controlled system, which enhances the overall speed and accuracy of the packing process, minimizing errors and ensuring consistency.

Stainless Steel Construction: Built with durable stainless steel, the WS-1200 is resistant to corrosion and wear, making it ideal for use in various industries, including food, pharmaceuticals, and consumer goods packaging.

User-Friendly Interface: The intuitive touch-screen control panel allows operators to easily monitor and adjust machine operations, providing real-time data for enhanced productivity and minimal downtime.

Flexible Packing Patterns: Capable of handling a wide range of product sizes and weights, the WS-1200 supports customizable packing patterns. This makes it suitable for various products, ensuring efficient space utilization within each box.

Reduced Labor Requirements: By automating the packing process, the machine significantly reduces the need for manual labor, minimizing the risk of human error and worker fatigue while increasing overall efficiency.

Versatile Product Handling: The robotic arm can pick and arrange products according to pre-programmed patterns, making it adaptable to a wide range of industries, including food, beverage, pharmaceutical, and more.

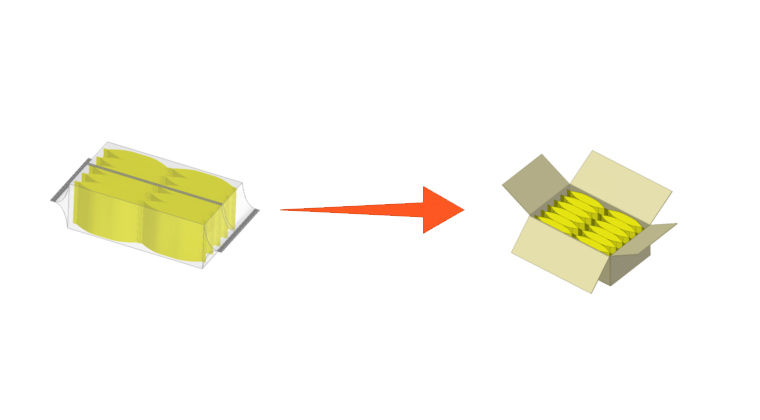

Application

Bag Type

Competitive Advantage

Compared with conventional mechanical case packers, which are limited by fixed motions and slower changeovers, the WS-1200 offers flexibility and adaptability through its 3+1-axis robotic design. While many competitor machines require separate models for different product types, the WS-1200 can handle multiple product categories and carton formats on a single system.

Its ability to support customizable packing patterns allows buyers to optimize carton utilization, reduce packaging waste, and adapt quickly to changing market demands. For manufacturers seeking a balance of speed, accuracy, and multi-product compatibility, the WS-1200 delivers higher ROI and reduces long-term operating costs compared to both manual labor and traditional mechanical packers.

Why Choose Soontrue?

Soontrue is a global leader in end-of-line packaging automation, providing innovative solutions tailored to diverse industries. The WS-1200 Robotic Box Packing Machine reflects Soontrue’s commitment to delivering flexible, high-precision, and globally supported automation systems. Buyers benefit from:

- 30+ years of experience in packaging machinery design and automation.

- Customizable solutions to fit specific industry and product requirements.

- Worldwide service network for fast installation, training, and technical support.

- Scalable ROI by reducing labor, improving safety, and increasing throughput.

With Soontrue, buyers gain not just a machine, but a long-term partner in efficiency and innovation.

FAQ - WS-1200 3+1-axis Robotic Box Packing Machine

Q1: What products can the WS-1200 handle?

It can pack cartons, bottles, bags, pouches, and irregular-shaped products, making it highly versatile across industries.

Q2: How fast can the WS-1200 pack cartons?

The machine achieves up to 3000 pcs/hour, depending on product size, carton dimensions, and packing patterns.

Q3: Can it handle multiple packing patterns?

Yes. The WS-1200 supports customized layouts through HMI programming, including single-product and mixed-product configurations.

Q4: How does it compare to conventional case packers?

Unlike mechanical systems with fixed movements, the WS-1200 uses a 3+1-axis robotic arm for faster changeovers, more flexibility, and higher accuracy.

Q5: Is it easy to integrate with existing packaging lines?

Yes. The WS-1200 is designed to integrate seamlessly with case erectors, sealers, conveyors, and palletizers as part of a fully automated end-of-line solution.

Q6: How does it improve ROI for manufacturers?

By reducing labor, minimizing errors, and enabling flexible production, the WS-1200 lowers costs and delivers faster payback compared with manual or traditional packing systems.