2-axis Robotic Box Packing Machine

Typical Applications

- Food & Beverage: cartons of snacks, biscuit trays, dairy bottles, beverage packs

- Pharmaceuticals & Healthcare: boxed medicines, supplements, personal care products

- Household Products: tissue cartons, detergent bottles, daily consumables

- Industrial Goods & Hardware: tools, electronic parts, hardware accessories

- Logistics & Distribution: products requiring reliable carton loading for shipping

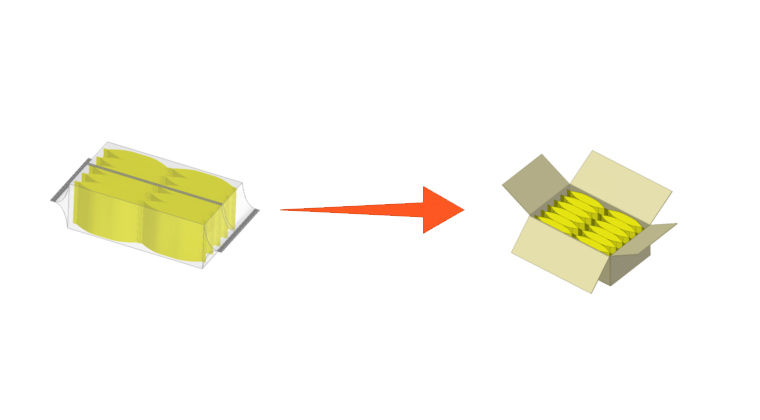

A 2-axis robotic box packing machine is an automated system that uses servo-driven robotic arms to pick, arrange, and load products into cartons with precision and efficiency.

With a payload capacity of up to 15kg per pick, it is suitable for handling cartons, bottles, pouches, blister packs, and trays. The 2-axis design makes it ideal for standardized packing patterns, offering stable throughput and consistent quality for repetitive packaging operations.

By reducing manual handling, minimizing errors, and improving workplace safety, this machine helps manufacturers increase productivity and ensure reliable carton packing across multiple industries.

How Robotic Box Packing Machines Work:

The robotic box packing machine operates using robotic arms to handle and pack products into boxes in an organized manner. The system typically includes sensors, vision-guided technology, and specialized grippers to accurately identify the position of the products and ensure they are securely placed in the boxes. Once packed, the boxes are sealed and prepared for further handling or shipping.

Machine Parameters

| Specifications | STI-DT2-700B | STI-DT2-1300B | STI-DT2-1500B | STI-DT2-1500B |

| Work distance | 130x700x130mm | 150x1300x150mm | 150x1500x150mm | 600x600x600mm |

| Max payload | 15kg | 16kg | 20kg | 50kg |

| Pickup speed |

40 times/min (under 8kg 130x700x130mm) |

20 times/min (under 10kg 600x600x600mm) |

20 times/min (under 10kg 300x600x800mm) |

15 times/min |

| Motor power | 750W*2 | 750W*2 | 1500W*2 | 1500W*2+400w |

| Robot weight |

78kg |

60kg | 75kg | 130kg |

📌 Reference: Internal test data by Soontrue R&D Lab (2024)

Key Features

- 2-axis Robotic Arm:Efficient, stable performance for standardized packing tasks.

- 15kg Payload Capacity:Handles medium-weight products as well as small packs.

- Versatile Product Handling:Cartons, bottles, blister packs, pouches, and trays.

- Consistent Accuracy:Servo-driven motion ensures reliable, repeatable packing.

- Customizable Grippers:Adaptable to different product shapes and sizes.

- Optional Vision System:Improves accuracy for irregular or randomly placed products.

- Integration Ready:Works with case erectors, conveyors, sealers, and palletizers.

- User-Friendly HMI:Multi-language touchscreen with recipe memory.

Application

Bag Type

Competitive Advantage

Compared with manual packing or conventional mechanical systems, the 2-axis robotic box packing machine delivers faster cycle times, fewer errors, and greater safety. Its ability to handle products up to 15kg gives it a wider application range than many competitor 2-axis systems limited to lightweight items.

While multi-axis robots are designed for complex motions, the 2-axis system provides an optimal solution for standard carton packing tasks, offering a reliable balance of payload, accuracy, and throughput.

Why Choose Soontrue?

Soontrue provides a full portfolio of end-of-line packaging solutions, ensuring the right fit for different industries and production needs. This 2-axis robotic case packer represents Soontrue’s commitment to delivering efficient, reliable, and globally supported automation. Buyers benefit from:

- Proven reliability for 15kg medium-weight product handling.

- Customizable grippers and optional vision systems.

- Seamless integration into case erecting, sealing, and palletizing lines.

- Worldwide service, training, and after-sales support.

By working with Soontrue, manufacturers gain a long-term partner dedicated to efficiency, safety, and strong ROI.

FAQ - 2-axis Robotic Box Packing Machine

Q1: What is the maximum payload capacity?

Up to 15kg per pick, suitable for medium-weight and standard products.

Q2: What product types can it pack?

It handles cartons, bottles, blister packs, trays, and pouches.

Q3: How accurate is the packing system?

The servo-driven 2-axis arm ensures precise placement and stable performance.

Q4: Can it adapt to different products?

Yes. With customizable grippers and optional vision systems, it adjusts to various product shapes and orientations.

Q5: How does it integrate with existing packaging lines?

It works seamlessly with case erectors, conveyors, sealers, and palletizers.

Q6: How does it improve workplace safety?

By automating heavy and repetitive lifting tasks, it reduces manual labor and minimizes injury risks.