Top 10 Food Packaging Machine Problems and How to Fix Them for 2026

Packaging Knowledge Hub

If you're seeking packaging automation solutions, please contact us, and we'll be delighted to offer you the most tailored solution.

An essential resource for Food Processing Factories, Machinery Distributors, and Service Agents to maximize OEE and minimize waste.

Summary: The Cost of Downtime in Food Packaging

In the high-stakes world of food manufacturing, Overall Equipment Effectiveness (OEE) is the metric that matters. For a food processing factory, a packaging machine that stops for 10 minutes every hour due to film jamming or seal failures isn't just an annoyance—it is a massive leak in profitability. For packaging machinery agents and distributors, these issues represent warranty claims, frustrated clients, and a reputation risk.

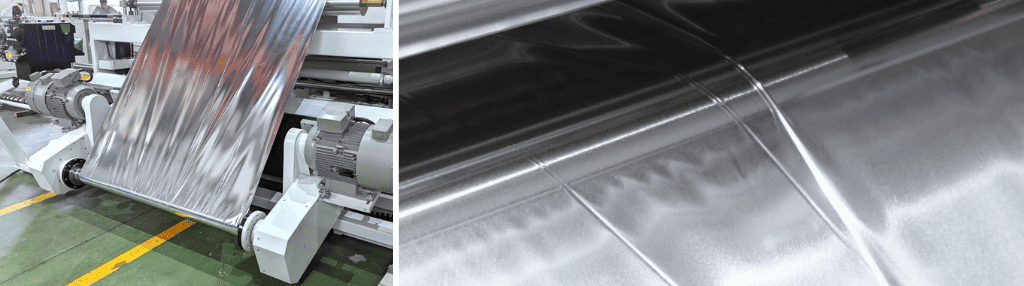

As we move into 2026, the complexity of packaging machinery—specifically Vertical Form Fill Seal (VFFS) Machine and Flow Wrapping Machine—has increased with the adoption of sustainable, thinner films and high-speed automation.

This guide provides a structured, technical breakdown of the top 10 packaging machine problems. It is written to serve as a "first response" manual, helping operators diagnose root causes and implement fixes before calling for expensive external support.

Quick Troubleshooting Lookup Table

| Problem / Symptom | Likely Root Cause |

|---|---|

| 1. Film Drifting / Off-Center | Roller misalignment; Spindle not centered; Dirty belts |

| 2. Film Snapping / Breaking | Excessive brake tension; Damaged film roll edges |

| 3. Wrinkling / Creases | Forming set wear; Misaligned rollers; High tension |

| 4. Weak or Leaking Seals | Low temp/pressure; Thermocouple failure |

| 5. Seal Contamination | Product "stringing"; Static electricity; Timing off |

| 6. Burnt / Melting Film | SSR failure (runaway temp); Worn Teflon tape |

| 7. Inconsistent Bag Length | Belt slippage; Dirty sensor lens; Loose encoder |

| 8. Dull Knife / Ragged Cut | Blade wear; Anvil wear; Product buildup in slot |

| 9. Date Code Missing/Faint | Low air pressure (<4 bar); Ribbon out; Signal timing |

| 10. Product Blockage / Jams | Tube too narrow; Frozen clumps; Flap gate failure |

Section 1: Film Tracking and Forming Issues

The most common source of unplanned downtime involves the "web" or film path. If the film doesn't behave, the machine cannot run.

1. Troubleshooting VFFS Film Tracking and Misalignment

The Problem: The film web drifts to the left or right as it travels over the forming shoulder, resulting in off-centre back seals or bags that are not square.

Symptom: The vertical seal is not centred on the back of the bag; the film edge is curling; the machine stops due to "film runout" errors.

Root Cause Analysis:

- Roller Misalignment: One of the carriage rollers is not parallel to the others.

- Uneven Pressure: The pull belts (friction belts) are exerting uneven pressure or speed on the film.

- Spindle Position: The film roll itself is not centered on the spindle.

The Fix:

Check the Spindle: Ensure the film roll is perfectly centred, and the core chucks are tight.

- Clean the Pull Belts: Dust from food products (like sugar or flour) can coat one belt, reducing friction. Clean both belts with alcohol.

- Adjust the Film Carriage: Use the machine’s handwheel or HMI (on automatic tracking systems) to shift the carriage. If the film tracks are left, move the carriage right.

2. Resolving Film Breakage and High Tension Errors

The Problem: The film snaps suddenly during operation, causing a hard stop and requiring a time-consuming re-threading process.

Symptom: A loud "snap" sound followed by a machine alarm; the film looks stretched or necked down at the break point.

Root Cause Analysis:

- Excessive Brake Tension: The unwind brake is set too high for the film gauge.

- Dancer Arm Issues: The dancer arm (which buffers tension) is bottoming out or sticking.

- Damaged Roll: The film roll has nicked edges from poor handling in the warehouse.

The Fix:

- Inspect the Roll: Check the sides of the film roll for cuts. A 1mm nick can cause a tear under tension. Remove the damaged layers.

- Calibrate the Brake: Lower the unwind tension settings on the HMI. The film should be taut but not "singing" like a guitar string.

- Lubricate Bearings: Ensure all idler rollers spin freely. A seized bearing acts like a brake.

3. Fixing Film Wrinkling and Creasing on Packages

The Problem: The finished bag looks sloppy, with creases or wrinkles in the seal areas, compromising the hermetic seal needed for food preservation.

Symptom: Diagonal wrinkles on the front of the bag; "tunnels" in the end seals where air can escape.

Root Cause Analysis:

- Forming Set Wear: The forming shoulder (collar) is worn or has product buildup.

- Roller Alignment: The rollers feeding the forming tube are not square.

- Temperature Differential: The film is threading through a path that is too hot or too cold, causing warping.

The Fix:

- Align the Forming Set: Ensure the forming tube is perfectly vertical and aligned with the film path.

- Adjust Roller Parallelism: Use a level to ensure all feed rollers are parallel to the forming tube.

- Reduce Tension: High tension often pulls the film into wrinkles. Reduce the vertical seal pressure slightly.

Section 2: Sealing Integrity and Food Safety

For food factories, a bad seal means spoilage, oxidation, and recalls. For distributors, it means the machine isn't performing to spec.

4. Diagnosing Weak or Leaking Heat Seals

The Problem: The bag opens during transport or fails a water-bath leak test. This is critical for MAP (Modified Atmosphere Packaging) applications.

Symptom: The seal peels apart easily; air leaks out when the bag is squeezed.

Root Cause Analysis:

- The "Three T's" Imbalance: Time (Dwell), Temperature, and Pressure are not optimized.

- Thermocouple Failure: The HMI reads 150°C, but the jaw is actually at 120°C.

- Jaw Misalignment: The sealing jaws are not closing parallel to each other.

The Fix:

- Verify Temperature: Use an external pyrometer to check the actual face temperature of the jaws. Replace faulty heater cartridges or thermocouples.

- Increase Pressure: Check the pneumatic air pressure (usually requires 6 bar/90 psi). Increase the mechanical jaw pressure if using a servo system.

- Check the Serrations: Inspect the jaw face. Worn serrations cannot grip the film to fuse it.

5. Preventing Product Contamination in the Seal Area

The Problem: Food particles (crumbs, powder, liquid) get trapped in the seal, preventing the plastic layers from fusing.

Symptom: The seal looks "dirty" or granular; the bag leaks specifically at the point of contamination.

Root Cause Analysis:

- Timing Issues: The jaws are closing before the product has fully fallen (Product "Stringing").

- Static Electricity: Dusty products (spices, coffee) cling to the film due to static.

- Overfilling: The bag is too small for the volume of product.

The Fix:

- Adjust "Stagger Dump": Delay the jaw closing time on the HMI to allow the product to settle.

- Install Static Eliminators: Use ionising bars near the forming tube to neutralize static charge.

- Clean the Jaws: Use a brass brush (never steel) to clean burnt product off the sealing jaws.

6. Correcting Overheating and Burnt Packaging Film

The Problem: The film is melting, shrinking excessively, or sticking to the jaws, causing jams.

Symptom: Smoke rising from the jaws; the seal is transparent or brittle; plastic residue builds up on the Teflon tape.

Root Cause Analysis:

- Runaway Temperature: A Solid State Relay (SSR) has failed in the "closed" position, sending continuous power to the heaters.

- Slow Speed: The machine speed was reduced, but the sealing temperature wasn't lowered to match.

The Fix:

- Check the SSR: If the heaters stay on even when the temperature setpoint is reached, replace the SSR.

- Replace Teflon Tape: Worn Teflon tape exposes the film to bare metal. Replace it regularly.

- Enable "Auto-Temp" Features: Many modern machines automatically adjust seal temp based on machine speed. Ensure this is active.

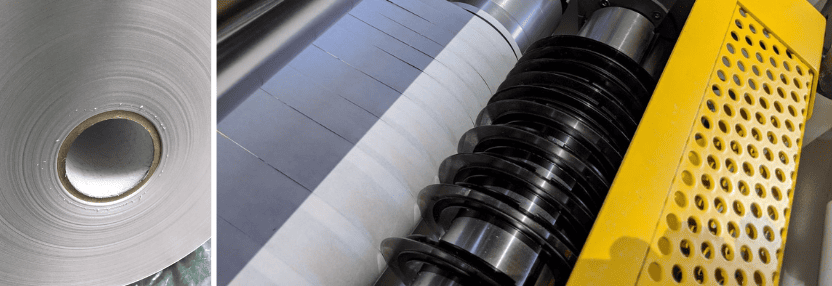

Section 3: Cutting and Dimensional Accuracy

Aesthetics matter. A bag that is cut poorly or is the wrong size affects shelf appeal and secondary packaging (boxing).

7. Solving Inconsistent Bag Length Variations

The Problem: The bags vary in length by 5mm to 20mm, causing the design to drift and the machine to miss the "Eye Mark."

Symptom: The registration mark (black spot) moves up and down on the finished bag; the machine cuts through the logo.

Root Cause Analysis:

- Belt Slippage: The pull belts are worn or glazed and are slipping on the film.

- Sensor Glitch: The photo-eye sensor lens is dirty or not calibrated to the contrast of the film.

- Encoder Coupling: The encoder measuring film length is loose.

The Fix:

- Clean/Replace Belts: If belts are shiny or smooth, replace them.

- Teach the Sensor: Perform a "Teach" function on the registration sensor so it clearly distinguishes the dark mark from the background.

- Check Film Path Tension: If the film is too loose, the encoder cannot measure it accurately. Increase dancer tension.

8. Fixing Dull Knife and Ragged Cut Issues

The Problem: The bag separation is not clean. The cut edge is jagged, or bags remain attached to each other (chaining).

Symptom: "Hanging" threads of plastic; the machine makes a loud "thud" when cutting; bags don't drop.

Root Cause Analysis:

- Dull Blade: Packaging knives wear out, especially when cutting abrasive paper films or thick laminates.

- Anvil Wear: The opposing slot (anvil) where the knife enters is worn out.

- Spring Failure: The springs that fire the knife are fatigued.

The Fix:

- Rotate or Replace Knife: Most industrial knives are disposable. Do not sharpen; replace.

- Shim the Knife: If the blade isn't extending far enough, adjust the shims or cam settings.

- Clean the Slot: Product buildup in the knife slot prevents the blade from fully extending.

Section 4: Coding and Product Flow

The "Brain" and "Stomach" of the operation. Ensuring compliance and flow.

9. Troubleshooting Date Code Printer Failures

The Problem: The Expiry Date or Batch Code is missing, faint, or placed in the seal area (where it can't be read).

Symptom: Faded text; ribbon breaking; printer error alarms.

Root Cause Analysis:

- Ribbon/Ink Out: Simple consumable exhaustion.

- Air Pressure: Thermal Transfer Overprinters (TTO) require air pressure to press the printhead against the film.

- Signal Timing: The "Print Go" signal is sent at the wrong time in the machine cycle.

The Fix:

- Check Air Supply: Ensure the printer has at least 4 bars of pressure.

- Clean Printhead: Use an isopropyl alcohol wipe to clean the printhead pixels.

- Adjust Delay: Change the print delay setting in the HMI to move the code position away from the seal.

10. Clearing Product Blockages and Bridging

The Problem: The machine is running, but the bags are empty (or light), or the product jams inside the forming tube.

Symptom: "Empty Bag" detection alarm; product spilling onto the floor; inconsistent weights.

Root Cause Analysis:

- Bridging: Sticky or large products (like frozen broccoli or gummy candies) clump together in the tube.

- Tube Diameter: The forming tube is too narrow for the product size.

- Flap Gate Failure: The gate that catches the product before the dump is stuck.

The Fix:

- Use a Poker/Vibrator: Install a pneumatic vibrator on the forming tube to keep the product moving.

- Check Product Prep: Ensure frozen foods are individually quick frozen (IQF) and not clumped before entering the hopper.

- Inspect Transition Chutes: Ensure the Teflon coating on the chutes is intact to reduce friction.

Section 5: Preventive Maintenance

To prevent the "Top 10" problems listed above, a proactive maintenance schedule is essential. Food processing factories should implement the following checklist:

|

Frequency |

Maintenance Task |

Target Issue Prevented |

|

Daily |

Clean sealing jaws with brass brush |

Burnt seals, Leaks |

|

Daily |

Clean pull belts and vacuum drive |

Film tracking, Bag length errors |

|

Weekly |

Inspect Teflon tape and cutting knife |

Ragged cuts, Film sticking |

|

Monthly |

Lubricate bearings and check chain tension |

Mechanical jams, Noise |

|

Quarterly |

Calibrate temperature and pressure sensors |

Seal integrity, Safety compliance |

Conclusion: Empowering the Food Packaging Line

For Food Processing Factories, understanding these 10 common faults transforms the operator from a passive button-pusher into an active problem solver. It reduces the "Mean Time to Repair" (MTTR) and protects the bottom line.

For Distributors and Agents, sharing this knowledge builds trust. When you help a client fix a film tracking issue over the phone using this guide, you aren't just a vendor; you are a partner in their production success.

Key Takeaway for 2026: The future of packaging is automated, fast, and sustainable. However, the fundamentals of heat, time, pressure, and tension remain unchanged. Master these variables, and you master the machine.

While mastering troubleshooting is essential, starting with reliable equipment is the ultimate preventive measure. This is why many factories partner with Soontrue, relying on our stable mechanical structures, precise servo controls, and long-term cost efficiency to minimize these common disruptions from day one.