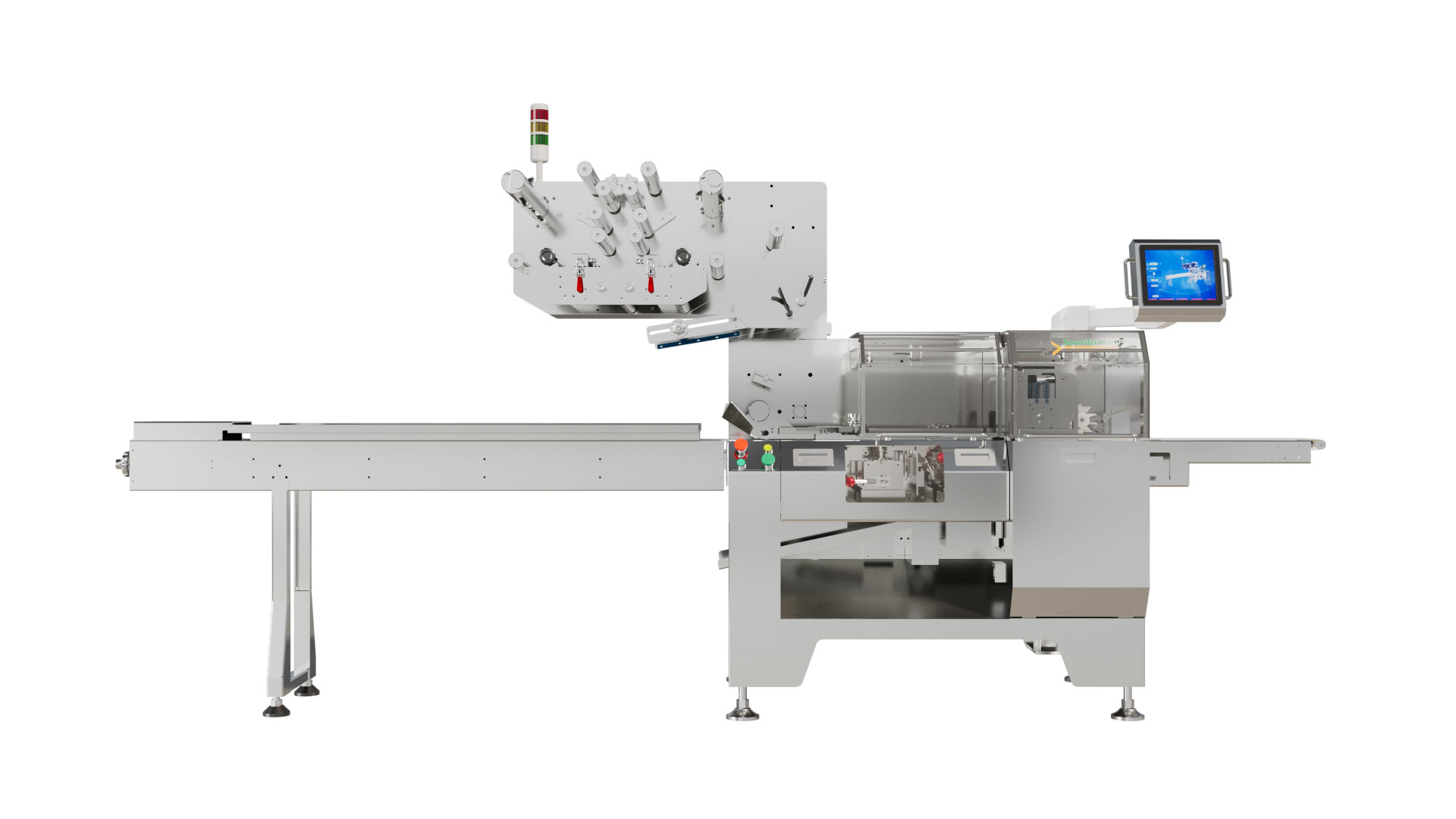

SZ590 High Speed Flow Packaging Machine

SZ590 High Speed Packaging Machine Typical Applications

- Snacks & Confectionery – Biscuits, chocolate bars, candy, energy bars, bakery snacks

- Medical & Pharmaceutical – Masks, bandages, small medical devices and healthcare items

- Daily Care Products – Soaps, toothbrushes, wet wipes, small household consumables

The SZ590 is a high-speed pillow packaging machine built for fast, reliable, and versatile performance. Unlike standard flow wrappers, the SZ590 is engineered to run not only traditional films (OPP/CPP, OPP/PE) but also special barrier films such as VMBOPP, VMCPP, and VMPET.

This capability allows manufacturers to extend product shelf life, improve barrier protection, and achieve premium packaging quality. Combined with its high-speed rotary sealing technology and advanced control system, the SZ590 is a preferred choice for frozen food, snacks, daily goods, and pharmaceutical packaging.

Why It Matters

- High-Speed Output – Designed for factories with large-scale production needs.

- Barrier Film Compatibility – Handles VMBOPP, VMCPP, VMPET for extended freshness.

- Premium Packaging Quality – Strong sealing with enhanced product protection.

- Wide Industry Use – Covers food, pharma, frozen products, and daily care items.

How It Works

- Film Feeding – Film (90–400mm wide) is automatically pulled and positioned.

- In-feed Conveyor – Items are aligned and conveyed into the forming area.

- Wrapping & Forming – Film wraps around the product into a pillow-style pack.

- Sealing & Cutting – Rotary jaws seal the pack ends and cut individual packs.

- Out-feed Conveyor – Finished packages exit for secondary packing or direct distribution.

👉 In short, the SZ590 combines speed, flexibility, and film versatility, delivering reliable packaging for demanding industries.

Machine Parameters

| Specifications | SZ-590 | SZ-580 (double cutter) | SZ-580 (double cutter) | SZ-580 (Triple cutter) |

| Center distance | 105 mm | 132 mm | 90 mm | |

| Bagging size range | L60-350 mm | L60-400 mm | L60-500 mm | L45-300 mm |

| W35-160 mm | W35-130 mm | W35-160 mm | W35-80mm | |

| Product size range | H 5-60 mm | H 5-40 mm | H 5-60 mm | H 5-30 mm |

| Packing speed | 30-350 bags/min | 30-350 bags/min | 30-350 bags/min | 30-500 bags/min |

| Packing film width | 90-400 mm | 90-400 mm | 90-400 mm | 90-400 mm |

| Power supply | 220V/1Ph/50Hz | 220V/1Ph/50Hz | 220V/1Ph/50Hz | 220V/1Ph/50Hz |

| General power | 8.5 KW | 6.9 KW | 7.3 KW | 6.6 KW |

| Machine weight | 920 kg | 450 kg | 450 kg | 450 kg |

| Machine dimensions | 4420x1010x1940mm | 4200x970x1640mm | 4200x970x1640mm | 4200x970x1640mm |

| Packing material | OPP/CPP, PT/PE, KOP/CPP, VMBOPP, VMCPP, VMPET | PP, PVC, PS, EVA, PET, PVDC+PVC, OPP/CPP, etd. | ||

| View Machine | ||||

📌 Reference: Internal test data by Soontrue R&D Lab (2024)

Key Features

- High-Speed Performance – Efficient rotary sealing for large-scale production.

- Barrier Film Compatibility – Runs VMBOPP, VMCPP, VMPET to extend shelf life and product protection.

- Flexible Film Width – Handles packaging films from 90–400mm.

- Versatile Product Range – Ideal for snacks, frozen dumplings, medical items, and daily goods.

- Stable Sealing Technology – Strong, airtight seals across multiple film types.

- User-Friendly Interface – Touchscreen control with recipe memory for quick changeovers.

- Durable Stainless Steel Construction – HACCP, CE, and FDA compliant.

- Integration Ready – Works with upstream feeders and downstream cartoning/boxing systems.

Application

-

Biscuit & Cookie Packaging Solutions

-

Bread & Bakery Packaging Solution

-

Disposable Goods Packaging Solutions

-

Candy Packaging Solutions

-

Chocolate Packaging Solutions

-

Noodle Packing Solutions

-

Hardware Packaging Solutions

-

Household & Hotel Goods Packaging Solutions

-

Medical Supplies Sterile Packaging Solutions

Bag Type

Competitive Advantage

Compared with conventional pillow packing machines, the SZ590 offers:

- More Film Options – Runs premium barrier films (VMBOPP, VMCPP, VMPET) that many machines cannot handle.

- Better Shelf Life – Barrier packaging improves freshness and storage stability.

- Faster Throughput – High-speed design reduces cost per pack and increases productivity.

- Market Differentiation – Premium packaging improves consumer appeal and brand positioning.

- Flexible Production – Suitable for a wide range of industries within 90–400mm film width.

Why Choose Soontrue?

Soontrue is a global leader in packaging automation, trusted by food and consumer goods manufacturers worldwide. With the SZ590, you gain:

- Advanced Sealing Technology – Proven rotary sealing system for high-barrier films.

- Custom Solutions – Tailored to your product size and packaging needs.

- Global Service Network – Installation, training, and 24/7 technical support.

- Long-Term ROI – Improved efficiency, reduced waste, and premium packaging quality.

FAQ - SZ590 High Speed Packaging Machine

Q1: What products can the SZ590 pack?

It is designed for small-to-medium items within 90–400mm film width, such as snacks, frozen dumplings, soap, and medical items.

Q2: Can it run both standard and barrier films?

Yes. It supports OPP/CPP, OPP/PE as well as VMBOPP, VMCPP, and VMPET.

Q3: Does barrier film packaging affect speed?

No. The SZ590 maintains high speed while sealing barrier films securely.

Q4: Why use barrier films?

Barrier films extend product shelf life, protect against moisture and oxygen, and provide premium packaging quality.

Q5: How easy is film changeover?

Very easy — touchscreen recipe memory enables quick switching between film types and product sizes.

Q6: Can it integrate with feeding and boxing systems?

Yes. It integrates seamlessly with upstream product feeders and downstream cartoning/palletizing lines.