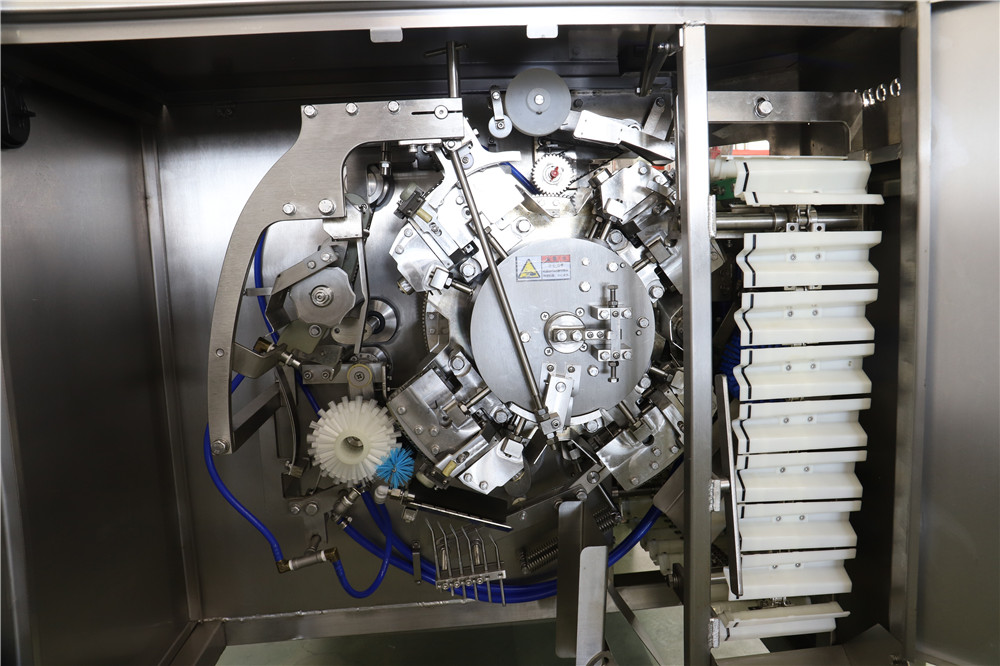

Hb320 Shrimp Peeling Machine

Shrimp Peeling Machine Typical Applications

- Shrimp Processing Plants – Industrial peeling operations for export-oriented factories

- Seafood Export Industry – Processing white shrimp, tiger shrimp, prawns for Europe, USA, Japan, and Asia

- Frozen Food Industry – Peeled shrimp ready for IQF freezing, packaging, and retail

- Catering & Retail Supply – Suppliers for restaurants, supermarkets, and hotels requiring large volumes of peeled shrimp

A Shrimp Peeling Machine is a seafood processing system designed to remove shrimp shells quickly, hygienically, and consistently. Traditional manual peeling requires large amounts of labor, is slow, and results in inconsistent quality. Soontrue’s automated peeling machine replaces manual labor with high-speed, reliable, and hygienic peeling technology, ensuring high yield and lower costs.

More than just a single-purpose tool, it forms a key part of a shrimp processing line alongside deheading, deveining, freezing, and packaging equipment, creating a fully automated shrimp processing workflow.

Why It Matters

- Labor Saving – Replaces dozens of workers with a single automated solution.

- Consistency & Quality – Ensures every shrimp is peeled cleanly with minimal damage.

- Flexibility – Handles multiple shrimp species and sizes with fast product switching.

- Scalability – Designed for medium to large shrimp processing factories targeting export markets.

How It Works

- Shrimp Feeding – Deheaded shrimp are loaded into the hopper or conveyor.

- Alignment & Separation – The system positions shrimp correctly for peeling.

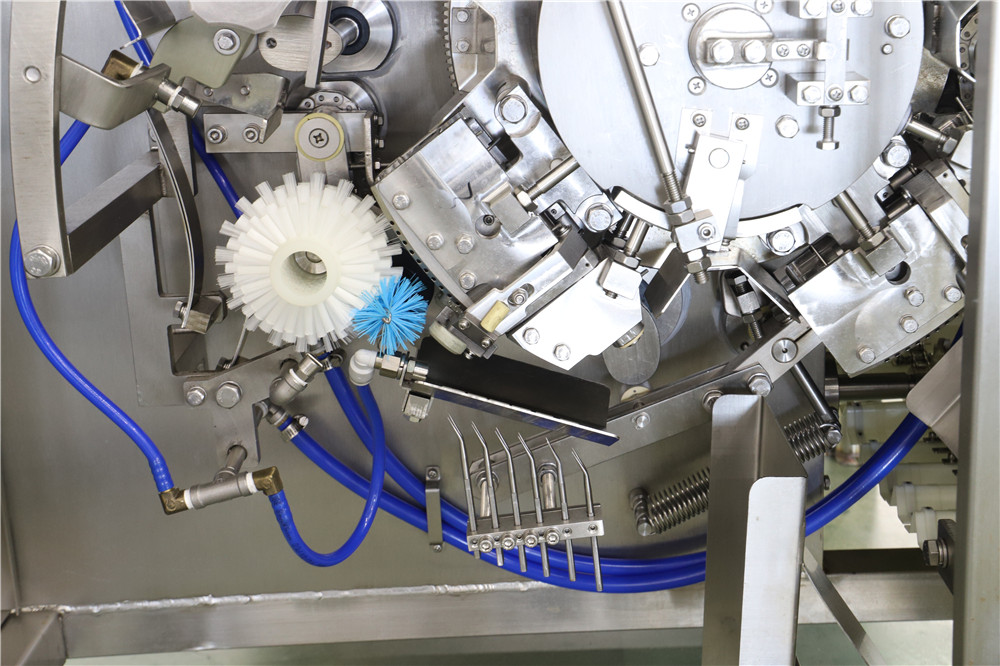

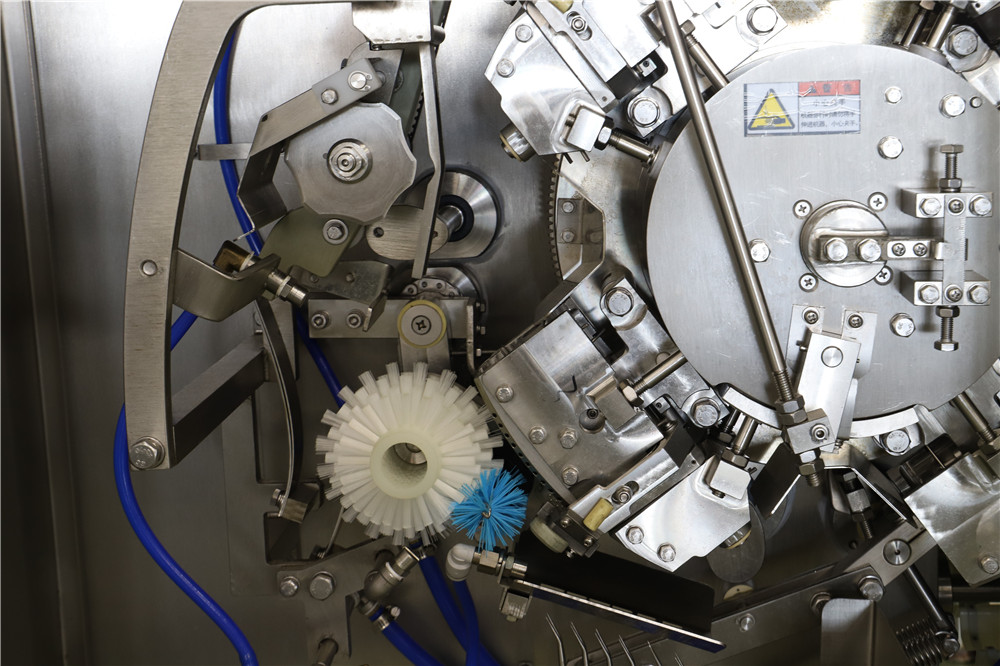

- Shell Removal – Precision rollers and peeling units separate the shells while protecting the meat.

- Washing & Cleaning – Peeled shrimp are rinsed to remove any remaining shell fragments.

- Output & Transfer – Clean shrimp are discharged to conveyors for freezing, grading, or packaging.

👉 In short, the machine turns raw deheaded shrimp into ready-to-cook peeled shrimp, at scale and with minimal human labor.

Machine Parameters

| Specifications | HB320 | ||||

| Shrimp spec | From 21/25 to 71/90 | ||||

| Peeling speed | Max. 70 pcs/min | ||||

| Water consumption | 120 L/h | ||||

| Water pressure | 0.4 mpa | ||||

| Greneral power | 1.5 Kw | ||||

| Power suppky | 220v/1Ph/50hz | ||||

| Machine weight | 230 kg | ||||

| Machine size | 1186×832x1274 mm | ||||

Key Features

- IP65 Waterproof Design with Display Shield

Designed for high-moisture environments, our shrimp peeling machine features an IP65 waterproof design, ensuring durability and resilience. The display screen has a waterproof shield, allowing for easy operation even under wet conditions.

- Quick Processing Style Change via Advanced HMI

Unlike conventional machines that require extensive adjustments, taking 30 minutes or more to switch processing styles, our shrimp peeling machine allows for a quick and seamless transition. Simply select the desired processing style on the touch screen, and the machine automatically adjusts its settings. This reduces downtime and increases production flexibility, making it easy to adapt to diverse consumer preferences and market demands.

- Multiple Processing Styles

This machine offers a wide range of processing options, including E-Z peeling, tail-on or tail-off, butterfly split, and more. The versatility enables businesses to meet specific customer and export requirements, providing tailored products for different markets.

- Seamless Integration into Production Lines

Our shrimp peeling machine is designed to be modular and can be easily integrated into a complete shrimp processing line. By combining it with additional equipment, you can create a fully automated production line that streamlines every stage of shrimp processing—from peeling to packing. This reduces manual labor, maximizes efficiency, and enhances productivity for large-scale operations.

- Versatile Peeling Capability: Handles shrimp sizes ranging from 21/25 to 71/90, making it adaptable for various market needs. Capable of producing up to 70 peeled shrimps per minute, ensuring high output.

- Multiple Processing Styles: Supports various peeling styles, including E-Z Peeling, Tail-On (2 to 4), Tail-On Deep Cut, Butterfly Split, Gradual Cut, Tail-Off Completely Peel, Shell Split, and Tail-On Completely Split. This flexibility enables processors to meet diverse consumer and market preferences.

- Servo Control System: The servo control reduces mechanical transmission needs, simplifying the machine's maintenance and commissioning process while ensuring accuracy and reliability in the peeling process.

Competitive Advantage

Soontrue's shrimp peeling machine offers significant advantages over manual peeling and other suppliers' equipment:

- Versatility – Handles multiple shrimp species in one system.

- Faster Changeover – One-click shrimp type switching vs. competitors' manual adjustments.

- Better Usability – IP65 waterproof touchscreen for easy operation in demanding seafood factory environments.

- Higher Yield – Advanced peeling units reduce meat loss and keep shrimp intact.

- Global Reliability – Designed for large export factories, compliant with HACCP, CE, and FDA standards.

Why Choose Soontrue?

With decades of automation experience, Soontrue provides advanced seafood processing solutions to leading shrimp exporters worldwide. Our shrimp peeling machines are trusted by factories in Vietnam, Thailand, India, Ecuador, and Latin America.

Choosing Soontrue means:

- Industry Expertise – Proven success in global shrimp processing hubs.

- Turnkey Systems – From deheading to peeling, freezing, and packaging.

- Global Support – Overseas engineers, spare parts depots, and 24/7 service.

- Faster ROI – Reduced labor, higher throughput, and consistent product quality.

FAQ About Shrimp Peeling Machine

Q1: Can the machine handle different shrimp species and sizes?

Yes. The system supports white shrimp, tiger shrimp, prawns, and others, with adjustable settings.

Q2: How fast can I switch between different shrimp types?

With Soontrue's one-click switching function, it takes only seconds, while competitor machines require manual adjustments that increase downtime.

Q3: What is the peeling accuracy and yield?

The peeling rate reaches ≥95% with minimal meat loss, ensuring high yield and consistent quality.

Q4: How much labor can it save compared to manual peeling?

One machine can replace dozens of workers, reducing labor costs by up to 70%.

Q5: Will peeling damage shrimp meat?

No. The peeling system is designed for gentle handling, preserving shrimp meat integrity.

Q6: Is the touchscreen suitable for seafood processing environments?

Yes. The IP65 waterproof touchscreen is durable, user-friendly, and designed to withstand wet factory conditions.

Q7: Can the machine integrate with other shrimp processing equipment?

Yes. It connects seamlessly with deheading, deveining, freezing, and packaging systems.

Q8: What about hygiene and cleaning?

The stainless steel design is food-safe, easy to clean, and compliant with HACCP, FDA, and CE standards.